Engineers rely on 420 stainless for precision, strength, and durability across critical applications.

High Hardness and Wear Resistance

Stainless Steel 420 is renowned for its ability to achieve exceptional hardness levels through heat treatment, reaching up to 50–52 HRC. This makes it ideal for tools and components exposed to friction, abrasion, or repetitive motion. Once hardened, the steel delivers excellent edge retention and dimensional stability, ensuring parts like blades, dies, and molds maintain their cutting or shaping precision even under continuous industrial use.

Moderate Corrosion Resistance

Containing 12–14% chromium, 420 stainless forms a self-healing oxide film that provides resistance to moisture, steam, and mild chemical exposure. While not as corrosion-resistant as austenitic grades like 304 or 316, it performs reliably in controlled industrial or atmospheric environments. This property makes it suitable for applications where durability is critical, but aggressive chemical exposure is minimal.

Excellent Machinability in Annealed State

Before hardening, Stainless Steel 420 machines with exceptional ease due to its moderate carbon content (0.3%–0.4%) and uniform microstructure. In its annealed form, it allows tight-tolerance machining and intricate detailing without excessive tool wear or chatter. XC Machining takes advantage of this stage to create complex geometries, threads, and pockets before final heat treatment.

Strong Mechanical Stability

With a tensile strength of approximately 700–850 MPa, Stainless Steel 420 exhibits impressive mechanical stability. It resists deformation and maintains precision under heavy mechanical stress, impact, or vibration, an essential trait for aerospace, defense, and automotive systems. The alloy’s martensitic microstructure gives it high stiffness while retaining adequate elasticity to prevent cracking.

Versatilidad en todos los sectores

Stainless Steel 420 is a material that bridges performance and practicality. It can be machined, hardened, polished, and coated to suit multiple industrial needs—from medical scalpels and dental tools to automotive valve components and industrial blades. The alloy’s combination of aesthetic appeal, wear resistance, and formability allows manufacturers to use it in both functional and decorative applications.

How Is Stainless Steel 420 Applied Across Different Industries?

Stainless Steel 420 plays a vital role across multiple industries thanks to its exceptional combination of hardness, strength, and polishability.

Medical and Surgical Instruments

420 stainless is the material of choice for surgical instruments because it can be heat-treated to high hardness while retaining excellent polishability. This enables the creation of razor-sharp edges and mirror finishes, crucial for scalpels, scissors, and orthopedic tools that must cut cleanly and resist corrosion during sterilization cycles. XC Machining’s precision CNC and polishing processes ensure that medical-grade components meet ISO and FDA cleanliness and finish standards, combining sharpness with safety.

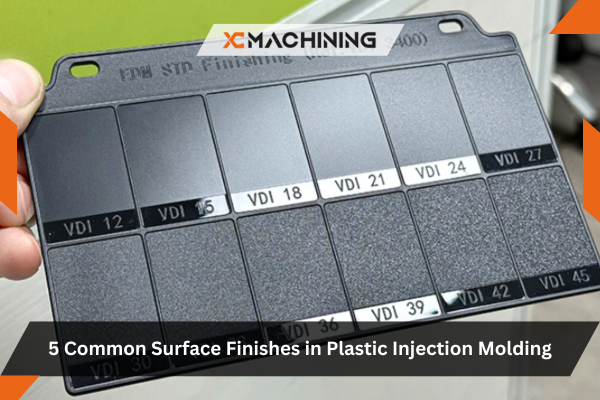

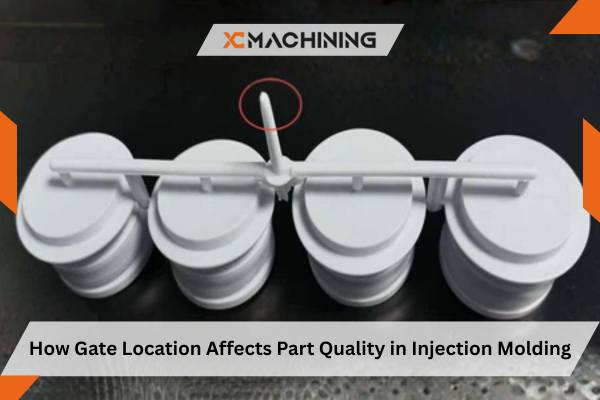

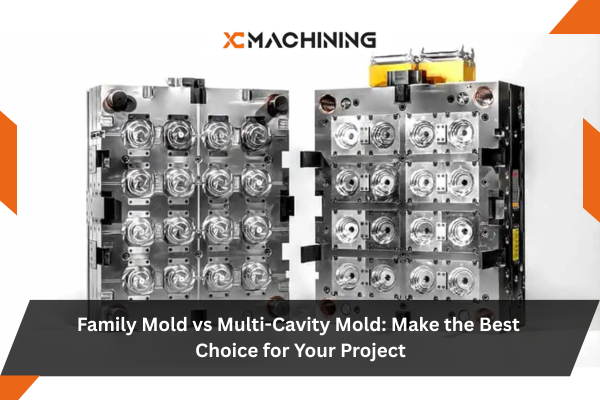

Tooling, Molds, and Dies

With its ability to achieve both hardness and high surface gloss, Stainless Steel 420 is widely used in injection molds, stamping dies, and cutting tools. The material resists surface wear and deformation, extending mold life even under continuous production. At XC Machining, we utilize controlled quenching and finishing to deliver molds with superior cavity smoothness and dimensional stability, minimizing maintenance and improving part ejection performance. It’s the go-to choice where precision meets longevity.

Aerospace and Defense Components

In aerospace and defense systems, 420 stainless provides an ideal balance between strength, weight, and corrosion resistance. It’s used for actuator shafts, control housings, locking pins, and precision fasteners that endure vibration, stress, and thermal fluctuation. The alloy’s ability to hold tolerances under dynamic load ensures mechanical reliability in mission-critical conditions. XC Machining’s aerospace-grade quality control ensures every 420 parts are produced to exact specifications and certified for demanding service environments.

Automotive and Mechanical Systems

In automotive and general machinery, Stainless Steel 420 plays a vital role in pump shafts, valve components, bushings, and bearings. Its resistance to friction, wear, and fuel corrosion allows it to operate reliably in lubricated and high-heat environments. XC Machining produces these parts with micro-finish surfaces that enhance oil film retention and reduce frictional loss, improving mechanical efficiency and component life. The result: fewer replacements and higher system uptime.

Consumer and Industrial Equipment

For products that require both durability and a polished aesthetic, such as knife blades, measurement tools, and optical housings, 420 stainless offers the perfect combination of form and function. Its ability to achieve a brilliant mirror finish enhances visual appeal while ensuring resistance to scratching and wear. XC Machining’s expertise in surface finishing and passivation helps transform raw 420 steel into premium-grade consumer and industrial parts that perform as beautifully as they look.