Plastic injection molding is one of the most common and versatile manufacturing methods used to produce plastic parts with high precision and consistency. This process involves injecting molten plastic material into a mold, where it cools and solidifies into the desired shape. The versatility of this technique allows manufacturers to create a wide range of plastic products, from simple components to intricate, complex designs.

At XC Machining, we specialize in offering servicios de moldeo por inyección de plásticos that ensure high-quality production for a variety of applications. Our advanced machinery and skilled team ensure that your project is handled with the utmost care, delivering consistent results on time and within budget.

Our Plastic Injection Molding Service Process

Plastic injection molding is a complex process that requires precision at every step to ensure high-quality production. Here’s a breakdown of the key stages involved in plastic injection molding:

Selección de materiales: The process begins with selecting the appropriate plastic material based on the part’s requirements. Common materials include thermoplastics like polyethylene, polypropylene, polystyrene, and ABS. The choice of material is based on factors such as strength, flexibility, and chemical resistance.

Mold Design and Creation: The next step is designing the mold, which is a critical component in achieving the desired shape and dimensions. The mold is typically made of steel or aluminum and consists of two parts that fit together to form the cavity where the plastic will be injected.

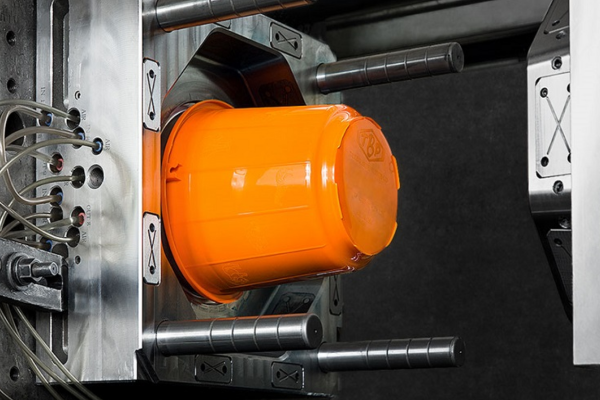

Injection of Plastic: The plastic material is heated until it becomes molten, allowing it to flow easily. The molten plastic is then injected into the mold cavity under high pressure, filling the mold completely.

Cooling and Solidification: Once the mold is filled, the plastic is allowed to cool and solidify. Cooling time is crucial, as it ensures that the plastic retains its shape and dimensions, minimizing defects.

Ejection of the Part: After the plastic has cooled and solidified, the mold is opened, and the part is ejected. Depending on the design, additional steps such as trimming excess material may be required.

Inspection and Quality Control: Every part produced goes through rigorous quality control testing to ensure that it meets the required specifications and is free of defects.

What Are The Advantages of Plastic Injection Molding?

Plastic injection molding offers numerous benefits that make it the preferred choice for producing plastic parts in high volumes. Here are some of the key advantages:

High Precision and Consistency: Once the mold is created, each part produced is virtually identical. This consistency ensures that the parts meet the exact specifications required, which is crucial for high-volume production.

Geometrías complejas: Plastic Molding Company allows for the production of parts with intricate designs and complex geometries that would be difficult or impossible to achieve using other manufacturing methods.

Eficacia y rapidez: The process is fast and efficient, allowing manufacturers to produce large quantities of parts in a short amount of time. This makes plastic injection molding an ideal solution for high-volume production.

Rentabilidad para la producción en serie: While the initial mold creation can be costly, the cost per unit decreases significantly as production volume increases, making plastic injection molding highly cost-effective for large-scale manufacturing.

Plastic Injection Molding Technologies

At XC Machining, we employ cutting-edge technology to enhance our plastic injection molding capabilities. Some of the advanced techniques we use include:

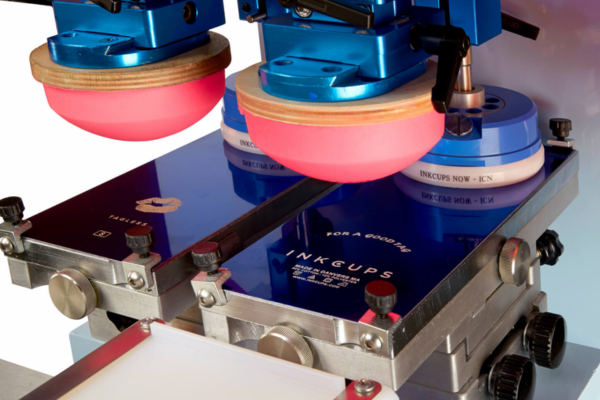

Multi-Shot Molding: This technique involves injecting different materials into the same mold, allowing us to create parts with multiple material properties in one cycle. This is ideal for parts that require different hardness or flexibility in different areas.

Moldeo por inserción: Insert molding involves placing metal or other inserts into the mold, allowing plastic to be injected around them. This creates strong, durable parts that combine plastic and metal in a single, efficient manufacturing process.

Gas-Assisted Injection Molding: This method uses gas to create hollow parts, reducing the material usage and weight of the final product. It also enhances the strength-to-weight ratio, which is ideal for certain applications.

These technologies enable us to produce high-quality plastic parts that meet the exact needs of our clients, whether the requirement is for a complex, multi-material part or a lightweight, durable component.

Get Started with XC Machining’s Plastic Injection Molding Services

If you’re looking for high-quality, efficient, and reliable moldeo por inyección de plástico services, XC Machining is here to help. Whether you need a prototype or high-volume production, our experienced team and cutting-edge technology ensure that your project is executed with precision and care.

Contact Us Today to learn more about how our plastic injection molding services can help bring your ideas to life! Let us help you achieve the highest standards in plastic manufacturing, ensuring quality, durability, and cost-effectiveness for your business.