.

What This Guide Covers

Understanding overmolding vs two shot molding is crucial when you’re designing products that combine multiple materials or colors. Both processes create multi-material parts, but they use fundamentally different approaches that affect your costs, design options, production speed, and product quality.

In this comprehensive guide:

- Clear explanation of overmolding and two shot molding processes

- Detailed comparison of overmolding vs two shot molding

- Pros and cons of each manufacturing method

- When to choose each process for optimal results

- Real-world examples and cost considerations

- Design guidelines for both approaches

Whether you’re developing consumer electronics with soft-touch grips, automotive components with integrated seals, or medical devices requiring multiple materials, understanding the overmolding vs two shot molding decision will help you choose the most effective manufacturing approach for your specific application.

Índice

Understanding Overmolding

After 12 years working with injection molding processes, I’ve guided dozens of clients through the overmolding vs two shot molding decision. Last quarter, a medical device company came to me wanting two shot injection molding for their new product. After reviewing their requirements, I explained why overmolding would actually save them $45,000 in tooling costs while delivering the exact functionality they needed. They went with overmolding and launched successfully within budget.

Overmolding is a two-step injection molding process where you first mold a substrate (base part), then place that substrate into a second mold where additional material is molded over or around it.

Cómo funciona el sobremoldeo

Step 1: Create the substrate

- Mold the first component (typically rigid plastic)

- Part fully ejects from the mold

- Allow part to cool completely

- Inspect and potentially store substrates

Step 2: Overmold the second material

- Manually or robotically load substrate into second mold

- Close mold around positioned substrate

- Inject second material (often TPE or silicone)

- Second material bonds to substrate

- Eject completed multi-material part

Key characteristic: The substrate physically moves from one mold to another between molding operations.

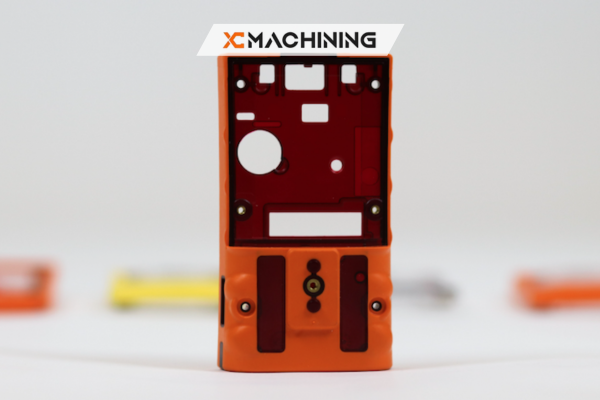

Common Overmolding Applications

Consumer products:

- Tool handles with rubber grips

- Toothbrush handles

- Phone cases with soft bumpers

- Kitchen utensil handles

Industrial equipment:

- Power tool grips

- Control knobs and handles

- Protective bumpers and seals

- Hand tool components

Real example: I worked on a power tool handle where we overmolded TPE onto a rigid nylon substrate. The two-step process allowed us to use different molding machines optimized for each material—a large press for the structural nylon handle and a smaller press for the TPE grip. This flexibility saved the client $28,000 annually in production costs compared to requiring a specialized two shot machine.

Understanding Two Shot Molding

Two shot molding (also called two shot injection molding or 2K molding) is an injection molding process where two different materials are molded sequentially in a single machine cycle without removing the part between shots.

How the Two Shot Injection Molding Process Works

Step 1: First shot

- Inject first material into the first cavity

- Part remains in mold (does not eject)

- Partial cooling occurs

Step 2: Mold rotation or core rotation

- Mold rotates to second position, OR

- Part transfers to second cavity position, OR

- Core rotates bringing first shot to second cavity

Step 3: Second shot

- Second material injects around or onto first shot

- Both materials are in the mold together

- Complete part cools as single unit

- Eject finished two-material part

Key characteristic: The part never leaves the machine between material injections. Everything happens in one continuous automated cycle.

Common Two Shot Injection Molding Applications

Automotive components:

- Dashboard components with soft-touch surfaces

- Interior trim with integrated seals

- Multi-color emblems and badges

- Door handle assemblies

Medical devices:

- Syringe bodies with integrated seals

- Multi-component diagnostic devices

- Surgical instruments with grips

Consumer electronics:

- Multi-color phone cases

- Remote controls with rubber buttons

- Computer mouse housings

- Game controller grips

Real application: A automotive supplier I consulted with produces 500,000 dashboard knobs annually using two shot injection molding. The automated process creates a rigid polycarbonate base with soft TPE surface in 45 seconds per part. Switching to overmolding would have required manual substrate loading, doubling cycle time and requiring additional labor.

Overmolding vs Two Shot Molding: Direct Comparison

Here’s how these processes compare across critical factors:

| Factor | Sobremoldeado | Two Shot Molding | Winner |

|---|---|---|---|

| Coste de utillaje | $15,000-$40,000 (two simple molds) | $60,000-$150,000 (complex rotating mold) | Overmolding (60-75% less) |

| Machine Cost | Standard machines ($80K-$200K) | Specialized two shot machines ($300K-$600K) | Sobremoldeado |

| Duración del ciclo | Slower (manual loading adds time) | Faster (fully automated) | Two Shot Molding |

| Labor Required | Higher (manual substrate loading) | Minimal (fully automated) | Two Shot Molding |

| Production Volume Suitability | Low to medium (under 100K parts/year) | Medium to high (over 100K parts/year) | Depends on volume |

| Flexibilidad de diseño | More flexible (can change processes easily) | Limited (committed to specific mold design) | Sobremoldeado |

| Part Quality | Excellent (good material bonding) | Excellent (superior bonding) | Tie (both excellent) |

| Compatibilidad de materiales | Wide range of combinations | Specific compatible material pairs | Sobremoldeado |

| Opciones de color | Unlimited (change substrate colors easily) | Limited to mold configuration | Sobremoldeado |

| Complejidad de la instalación | Simple (standard machines) | Complex (specialized equipment) | Sobremoldeado |

| Plazos de entrega | Shorter (simpler tooling) | Longer (complex mold fabrication) | Sobremoldeado |

Overmolding: Detailed Pros and Cons

Advantages of Overmolding

Lower tooling investment:

- Two separate, simpler molds cost less than complex rotating molds

- Easier to modify or repair individual molds

- Can prototype first material before committing to overmold tooling

Machine flexibility:

- Use standard injection molding machines

- Don’t need specialized two shot equipment

- Can use different machine sizes for each material

- Greater manufacturing flexibility

Design iteration:

- Easy to change substrate design without affecting overmold

- Can modify overmold without changing substrate mold

- Faster design iterations during development

- Lower cost for design changes

Compatibilidad de materiales:

- Wider range of material combinations possible

- Easier to bond dissimilar materials

- Can use surface treatments between shots if needed

- More forgiving material selection

Color and variant flexibility:

- Easy to produce multiple color combinations

- Can run different substrate colors through same overmold

- Low-cost way to offer product variants

- Good for customization and small batch variations

Real advantage: A consumer products client offered their handle in 6 color combinations. With sobremoldeo, they simply molded substrates in different colors and ran them all through the same overmold. Doing this with two shot molding would have required six different molds or complex color-change procedures.

Disadvantages of Overmolding

Higher labor costs:

- Requires manual or robotic substrate loading

- More handling increases contamination risk

- Labor costs multiply over high volumes

- Additional quality control steps needed

Slower cycle times:

- Substrate must be loaded between shots

- Total process takes longer than two shot

- Transfer time adds to overall production time

- Lower parts per hour output

Substrate handling challenges:

- Parts can get dirty or damaged during handling

- Requires careful positioning in overmold

- Misalignment can cause defects

- Storage and logistics between processes

Bond strength concerns:

- Substrate may cool completely, affecting bonding

- Surface contamination can prevent proper adhesion

- May require surface treatment for optimal bonding

- Quality depends on substrate cleanliness and positioning

Two Shot Molding: Detailed Pros and Cons

Advantages of Two Shot Injection Molding

Faster production:

- Fully automated process

- No manual handling between shots

- Higher parts per hour output

- Optimal for high-volume production

Superior bonding:

- First shot still warm when second shot applies

- Chemical bonding at molecular level

- Stronger material interface

- More durable finished parts

Consistent quality:

- Automated process reduces variation

- Perfect positioning every cycle

- No handling-related defects

- Better repeatability

Lower labor costs at volume:

- Minimal operator intervention

- One operator can run multiple machines

- Labor cost per part drops significantly at high volumes

- Automated quality control possible

Reduced contamination:

- Part never exposed between shots

- No handling contamination

- Cleaner production process

- Better for medical and food applications

Real benefit: A medical device manufacturer produces 2 million syringe components annually using the two shot injection molding process. The automated process ensures sterile production with zero handling contamination—impossible to achieve with overmolding.

Disadvantages of Two Shot Injection Molding

High tooling investment:

- Complex rotating or sliding molds expensive to build

- Difficult and costly to modify

- Long lead times for mold fabrication

- Higher financial risk if design changes needed

Specialized equipment required:

- Need dedicated two shot injection molding machines

- Machines cost 2-3x more than standard presses

- Not all manufacturers have this equipment

- Higher maintenance requirements

Limited design flexibility:

- Committed to specific mold configuration

- Design changes require expensive mold modifications

- Color changes may require new molds

- Less adaptable to product variations

Material restrictions:

- Materials must be chemically compatible

- Temperature requirements must align

- Not all material combinations work

- More testing needed to validate material pairs

Higher minimum volumes:

- Need high volumes to justify investment

- Break-even point typically 50,000-100,000+ parts

- Not economical for low-volume production

- Long-term production commitment required

When to Choose Overmolding

Based on analyzing hundreds of projects, choose overmolding when:

Production volumes are low to medium:

- Under 50,000-100,000 parts annually

- Product lifecycle uncertain

- Testing market before scaling

- Limited production runs

Budget constraints exist:

- Limited capital for tooling investment

- Need to minimize upfront costs

- Prefer to spread investment over time

- Startup or new product line

Design may evolve:

- Product still in development

- Likely to need design changes

- Want flexibility for iterations

- Testing different configurations

Multiple variants needed:

- Offering color options

- Different material combinations

- Customization requirements

- Producción de pequeños lotes

Existing equipment available:

- Already have standard molding machines

- Don’t want to invest in specialized equipment

- Using contract manufacturers with standard machines

- Flexible manufacturing strategy

Real decision: A startup developing ergonomic hand tools chose overmolding for their initial 15,000-unit production run. The lower tooling cost ($32,000 vs. $95,000 for two shot) allowed them to launch with less capital investment. After proving market demand, they can consider two shot molding for future high-volume production.

When to Choose Two Shot Injection Molding

Choose the two shot injection molding process when:

High production volumes:

- Over 100,000 parts annually

- Multi-year production commitment

- Stable, mature product

- Long-term volume projections

Labor costs are significant:

- High labor rates in your region

- Automation priority

- Running lights-out manufacturing

- Labor availability challenges

Quality consistency critical:

- Medical device applications

- Aerospace components

- Automotive safety parts

- Zero-defect requirements

Speed matters:

- Short cycle times required

- Maximum throughput needed

- Capacity constraints

- Just-in-time manufacturing

Design is finalized:

- Product design locked

- No anticipated changes

- Proven in market

- Committed to configuration

Real decision: An automotive tier-1 supplier producing 800,000 door handles annually invested $120,000 in two shot injection molding tooling. At their volume, the automated process saves $0.45 per part in labor costs compared to overmolding—a $360,000 annual savings that paid back the tooling investment in 4 months.

Cost Analysis: Overmolding vs Two Shot Molding

Break-even analysis example:

Assumptions:

- Part requires rigid substrate + TPE overmold

- Annual volume: 50,000 parts

- 5-year production life

Overmolding costs:

- Tooling: $35,000 (two simple molds)

- Cycle time: 90 seconds (includes loading)

- Labor: $0.75 per part (substrate loading)

- Machine cost: Standard equipment

Total 5-year cost: $222,500

Two shot molding costs:

- Tooling: $95,000 (complex rotating mold)

- Cycle time: 55 seconds (automated)

- Labor: $0.15 per part (minimal)

- Machine cost: Specialized equipment

Total 5-year cost: $202,500

Analysis: At 50,000 parts annually, two shot molding saves $20,000 over 5 years despite higher tooling costs. However, if volume drops below 35,000 parts annually or product life is under 3 years, overmolding becomes more economical.

Key insight: The overmolding vs two shot molding decision often comes down to volume and production timeline. Higher volumes and longer production runs favor two shot injection molding. Lower volumes and shorter runs favor overmolding.

Consideraciones sobre el diseño

For Successful Overmolding

Substrate design:

- Add undercuts or mechanical interlocks for grip retention

- Design smooth surfaces for consistent overmold bonding

- Consider substrate placement and alignment features

- Allow for substrate dimensional variation

Overmold design:

- Ensure adequate material thickness (typically 0.5-2mm minimum)

- Design for even material flow

- Plan gate locations carefully

- Account for different shrink rates

For Successful Two Shot Injection Molding

First shot design:

- Must remain stable during second shot injection

- Design for proper positioning in mold

- Account for thermal effects

- Create mechanical bonding features

Second shot design:

- Ensure material compatibility

- Match processing temperatures

- Design appropriate shot sizes

- Balance fill patterns

Compatibilidad de materiales

Common successful combinations:

Overmolding:

- PP substrate + TPE overmold

- ABS substrate + TPE overmold

- Nylon substrate + TPE overmold

- PC substrate + silicone overmold

Two shot injection molding:

- PP + TPE (same family materials)

- ABS + TPU

- PC + TPE

- Nylon + TPE (with proper grades)

Key principle: Two shot molding typically requires materials from compatible families that bond chemically. Overmolding is more forgiving and can accommodate a wider range of material combinations through mechanical bonding.

Conclusión

The overmolding vs two shot molding decision isn’t about which process is “better”—it’s about which approach best fits your specific project requirements, production volumes, and business constraints.

After 12 years of plastics manufacturing engineering, I’ve learned that overmolding excels for low-to-medium volumes, design flexibility, and lower capital investment. It’s ideal for startups, new products, customization, and applications where you need multiple variants. The manual substrate loading adds labor cost but provides manufacturing flexibility that’s valuable during product development and market testing.

Two shot injection molding dominates high-volume production where automation, speed, and consistency justify the higher tooling investment. It’s the right choice for mature products with stable designs, high volumes (typically over 100,000 parts annually), and long production runs. The automated process delivers superior bonding, faster cycle times, and lower per-part costs at volume.

Key decision factors in the overmolding vs two shot molding comparison:

- Under 50,000 parts/year: Overmolding usually wins

- Over 100,000 parts/year: Two shot injection molding typically more economical

- Design still evolving: Choose overmolding for flexibility

- Design locked, high volume: Invest in two shot molding

- Multiple color/material variants: Overmolding offers better flexibility

- Quality consistency critical: Two shot injection molding process advantages

The best approach is to calculate total cost of ownership over your expected production life, considering tooling, equipment, labor, cycle time, and volume. Sometimes a hybrid approach works—start with overmolding for market testing and initial production, then transition to two shot molding once volumes justify the investment.

Work closely with your manufacturing partners early in design. Whether choosing overmolding or two shot injection molding, their experience can guide design decisions that optimize your chosen process, reduce costs, and ensure manufacturing success.