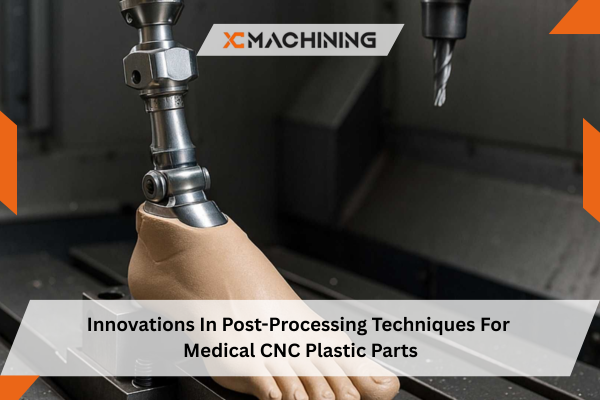

The medical device industry operates under some of the most stringent quality and safety requirements of any manufacturing sector. As medical CNC machining continues advancing, producing increasingly complex plastic components for surgical instruments, diagnostic equipment, implantable devices, and drug delivery systems, the post-processing techniques applied after initial machining have become equally critical to final part performance. While CNC machining for medical industry creates precise geometries and maintains tight tolerances, innovative post-processing methods transform raw machined parts into biocompatible, sterile, and functionally optimized medical components. Understanding these evolving post-processing innovations helps medical device manufacturers, engineers, and procurement professionals working with CNC machining parts suppliers make informed decisions that enhance product quality, regulatory compliance, and patient safety.

Índice

The Critical Role of Post-Processing in Medical CNC Machining

CNC médico turning and milling operations produce plastic parts with excellent dimensional accuracy, but the machined surface characteristics, internal stresses, surface energy properties, and sterilization compatibility often require enhancement through specialized post-processing. Unlike industrial or consumer applications where cosmetic appearance might drive finishing decisions, medical device CNC machining post-processing focuses on critical functional requirements including biocompatibility, bacterial resistance, sterilization durability, tribological performance, and optical properties.

Modern innovations in post-processing techniques address several key objectives specific to CNC machining medical devices:

Enhanced biocompatibility: Surface treatments that reduce adverse tissue reactions and improve integration with biological systems.

Improved sterilization resistance: Processes that enable parts to withstand repeated sterilization cycles without degradation or dimensional changes.

Optimized surface properties: Techniques creating specific surface energies, roughness profiles, or chemical characteristics required for medical applications.

Stress relief and dimensional stability: Methods eliminating machining-induced internal stresses that could cause warping or failure.

Functional surface modifications: Treatments adding antimicrobial properties, drug-eluting capabilities, or specific mechanical characteristics.

Advanced Surface Finishing Innovations

Surface finish quality directly impacts medical device performance, affecting bacterial adhesion, tissue compatibility, optical clarity, and cleanability. Recent innovations have expanded surface finishing capabilities beyond traditional polishing and buffing.

Automated Robotic Polishing Systems

Robotic polishing systems equipped with force-feedback sensors and adaptive programming now handle complex geometries in medical CNC plastic parts with unprecedented consistency. These systems address the variability inherent in manual polishing while achieving surface finishes down to 0.1 Ra (micrometers) on medical-grade plastics like PEEK, Ultem, and polycarbonate.

Advantages of robotic polishing for medical device CNC machining:

- Absolute repeatability across production runs eliminating operator-dependent variations

- Consistent pressure application preventing over-polishing or inadequate finishing

- Documentation and traceability of finishing parameters for regulatory compliance

- Reduced contamination risk compared to manual handling

- Complex geometry capability including internal passages and curved surfaces

Medical CNC machining facilities implementing robotic polishing report 40-60% reduction in finishing time for complex components while simultaneously improving finish consistency and reducing rejection rates.

Vapor Polishing Technology

Vapor polishing exposes plastic parts to controlled chemical vapor environments that selectively melt surface layers, creating exceptionally smooth, optically clear finishes without dimensional changes or introducing contaminants. This innovation particularly benefits optical medical devices, diagnostic equipment housings, and implantable components requiring pristine surfaces.

The process works by suspending parts in chambers containing solvent vapors calibrated to specific plastic types. PMMA (acrylic), polycarbonate, and polysulfone parts achieve optical clarity rivaling injection molding while maintaining the tight tolerances of CNC machining medical applications.

Recent innovations include:

- Multi-zone vapor systems providing differential finishing on single parts

- Real-time monitoring ensuring process consistency and documentation

- Environmentally friendly solvent alternatives reducing VOC emissions

- Automated handling systems preventing contamination during processing

Micro-Abrasive Flow Finishing

For internal passages, complex geometries, and features inaccessible to traditional finishing methods, micro-abrasive flow finishing forces abrasive-laden media through part features under controlled pressure. This innovation particularly benefits medical CNC turning operations producing cannulas, catheter components, and fluid handling devices where internal surface quality affects performance.

The technology removes burrs, smooths surfaces, and creates consistent finishes in areas where mechanical tools cannot reach. Recent developments incorporate:

- Non-embedded abrasives preventing particle contamination concerns

- Bio-compatible media formulations suitable for medical applications

- Programmable pressure profiles optimizing finishing for different geometries

- Real-time flow monitoring ensuring consistent processing

Innovative Sterilization-Compatible Treatments

Medical devices must withstand sterilization processes—autoclave steam, ethylene oxide gas, gamma radiation, or electron beam—without degradation. Innovations in post-processing now enhance plastic materials’ sterilization resistance while maintaining dimensional stability.

Radiation-Resistant Surface Modifications

Gamma and e-beam sterilization can degrade many engineering plastics through chain scission and oxidation. New surface treatment innovations create protective barriers or modify surface chemistry to resist radiation damage:

Plasma surface treatment: Low-pressure plasma processes modify surface layers without affecting bulk properties, improving oxidation resistance during radiation sterilization. Medical CNC facilities report 30-50% improvement in radiation resistance for PEEK and polysulfone components after plasma treatment.

Silicone-based barrier coatings: Ultra-thin silicone coatings applied through vapor deposition protect underlying plastics from radiation-induced oxidation while maintaining biocompatibility. These innovations enable plastics previously unsuitable for gamma sterilization to withstand multiple cycles without yellowing or embrittlement.

Antioxidant surface infusion: Controlled diffusion processes introduce antioxidants into surface layers, scavenging free radicals generated during radiation exposure. This technique extends the sterilization life of medical CNC plastic parts by 2-3 times compared to untreated materials.

Heat Stabilization Treatments

Autoclave sterilization subjects parts to 121-134°C saturated steam, challenging for many medical-grade plastics. Innovative heat stabilization post-processing expands autoclave compatibility:

Controlled annealing protocols: Precisely controlled thermal cycles relieve machining stresses while promoting crystallinity optimization, improving heat deflection temperatures by 10-20°C and enhancing autoclave resistance.

Cross-linking surface treatments: Chemical or radiation cross-linking of surface layers increases heat resistance without affecting bulk properties, enabling autoclave sterilization of components previously limited to lower-temperature methods.

Biocompatibility Enhancement Innovations

Beyond basic biocompatibility of raw materials, innovative post-processing techniques actively enhance biological compatibility and reduce adverse reactions.

Plasma-Enhanced Biocompatibility

Atmospheric and low-pressure plasma treatments modify surface chemistry and energy without altering bulk material properties. Different plasma chemistries create specific surface characteristics:

Recent innovations include atmospheric plasma systems enabling inline processing without vacuum chambers, reducing cycle times and costs while maintaining treatment effectiveness for CNC machining medical device components.

Antimicrobial Surface Treatments

Healthcare-associated infections drive demand for inherently antimicrobial medical device surfaces. Innovative post-processing techniques now incorporate antimicrobial properties into CNC machined plastic parts:

Silver nanoparticle incorporation: Controlled diffusion or ion implantation embeds silver nanoparticles in surface layers, providing durable antimicrobial activity without leaching concerns. This innovation particularly benefits surgical instruments, diagnostic equipment housings, and patient-contact surfaces.

Copper ion implantation: Ion beam technologies implant copper ions into plastic surfaces, creating long-lasting antimicrobial properties. Unlike coating methods, implantation ensures permanence through surface wear.

Quaternary ammonium surface modification: Chemical grafting attaches quaternary ammonium compounds to plastic surfaces, providing contact-kill antimicrobial properties. Recent innovations create covalent bonds ensuring permanence through cleaning and sterilization cycles.

Photocatalytic surface treatments: Titanium dioxide nanocoatings activated by ambient light provide continuous antimicrobial activity on CNC medical equipment housings and enclosures.

Stress Relief and Dimensional Stability Innovations

Mecanizado CNC médico introduces internal stresses that can cause dimensional changes during sterilization or service life. Advanced stress relief post-processing innovations ensure long-term stability.

Precision Thermal Conditioning

Traditional annealing processes have evolved into precisely controlled thermal conditioning protocols optimized for specific medical-grade plastics and geometries:

Multi-zone controlled cooling: Parts undergo heating followed by cooling at different rates in different zones, optimizing stress relief in thick and thin sections simultaneously. This innovation particularly benefits complex medical device CNC machining components with variable wall thicknesses.

Vacuum thermal processing: Stress relief occurs in vacuum environments preventing oxidation while enabling higher temperatures for thermally sensitive materials. Medical CNC facilities report 50% reduction in post-sterilization dimensional changes using vacuum thermal conditioning.

Rapid thermal annealing: Short-duration high-temperature exposure relieves surface stresses without affecting core material properties, ideal for thin-walled components where traditional annealing causes unacceptable dimensional changes.

Cryogenic Stress Relief

Innovative cryogenic processing—exposing parts to -80°C to -196°C—provides alternative stress relief mechanisms particularly effective for certain medical plastics:

Benefits of cryogenic post-processing:

- Relieves machining stresses through thermal contraction/expansion cycling

- Enhances crystallinity in semi-crystalline polymers improving mechanical properties

- Improves dimensional stability during subsequent sterilization cycles

- Reduces residual monomer content in some materials enhancing biocompatibility

Recent implementations combine cryogenic treatment with controlled warming cycles, optimizing stress relief while preventing thermal shock damage. Torneado CNC médico operations producing precision components report 30-40% improvement in long-term dimensional stability.

Optical Enhancement Innovations

Medical devices increasingly incorporate optical features—lenses, light pipes, viewing windows, diagnostic sensors—requiring exceptional optical clarity and specific light transmission characteristics.

Advanced Optical Polishing Systems

Beyond achieving surface smoothness, innovative optical polishing for medical CNC plastic parts addresses:

Birefringence reduction: Stress-induced optical distortions are minimized through optimized polishing sequences combined with thermal conditioning, critical for diagnostic imaging equipment and optical surgical instruments.

Controlled surface geometry: Diamond turning followed by specialized polishing maintains optical prescription accuracy while achieving necessary surface quality. This innovation enables CNC machining for medical industry optical components previously requiring molding.

Anti-fog and anti-reflection treatments: Plasma treatments and nano-coatings applied post-machining provide functional optical properties. Recent developments create durable treatments withstanding repeated sterilization.

Laser Surface Texturing

Ultrafast laser systems create controlled micro-textures on optical surfaces, producing:

- Anti-glare properties for viewing windows and displays

- Controlled light diffusion for diagnostic illumination systems

- Hydrophobic surfaces preventing fogging in endoscopic applications

- Directional light transmission for fiber optic coupling components

This innovation enables functional optical features impossible to machine conventionally, expanding capabilities of medical device CNC machining for sophisticated optical applications.

Surface Energy Modification for Assembly and Bonding

Medical devices often require adhesive bonding, ultrasonic welding, or coating application. Innovative surface energy modification post-processing optimizes these assembly processes.

Atmospheric Plasma Treatment for Adhesion

Inline atmospheric plasma systems treat CNC machined plastic parts immediately before bonding or coating operations, ensuring optimal surface energy:

Applications in medical device assembly:

- Enhanced adhesive bonding strength for hermetic seals in implantable devices

- Improved ultrasonic welding quality in drug delivery systems

- Better coating adhesion for antimicrobial or lubricious surface treatments

- Consistent printing quality for patient information and regulatory markings

Recent innovations include real-time surface energy monitoring confirming treatment effectiveness and integration with automated assembly lines for seamless processing.

Chemical Etching Innovations

Controlled chemical etching creates microscopic surface textures enhancing mechanical interlocking for adhesives while introducing functional groups improving chemical bonding. New etching chemistries specifically formulated for medical-grade plastics provide:

- Biocompatible etchant formulations leaving no harmful residues

- Selective etching affecting only surface layers without dimensional changes

- Uniform treatment even on complex geometries from medical CNC turning operations

- Rapid processing times compatible with production throughput requirements

Contamination Control and Cleaning Innovations

Medical device cleanliness requirements exceed most other industries. Innovative post-processing cleaning techniques ensure CNC machined plastic parts meet stringent contamination limits.

Supercritical CO2 Cleaning

Supercritical carbon dioxide cleaning systems remove machining oils, particulates, and organic contaminants without leaving residues or requiring drying. This innovation addresses limitations of solvent and aqueous cleaning:

Advantages for medical CNC machining:

- Zero residue eliminating contamination concerns

- Penetrates complex geometries and blind holes thoroughly

- Environmentally benign with no hazardous waste generation

- Compatible with all medical-grade plastics without degradation

- Verifiable cleanliness through inline monitoring

Medical device manufacturers report achieving cleanliness levels meeting ISO 13485 and FDA requirements consistently while reducing cleaning cycle times by 40-50% compared to traditional methods.

Plasma Cleaning and Sterilization

Low-pressure plasma systems now provide combined cleaning and sterilization in single processes. Oxygen or hydrogen peroxide plasma removes organic contaminants while simultaneously providing low-temperature sterilization suitable for heat-sensitive medical CNC plastic parts.

Recent innovations include:

- Continuous monitoring validating both cleaning and sterilization effectiveness

- Automated documentation for regulatory compliance

- Reduced cycle times through optimized plasma chemistry

- Material compatibility verification preventing polymer degradation

Quality Verification Innovations

Post-processing effectiveness must be verified through advanced inspection techniques ensuring medical device performance and regulatory compliance.

Non-Contact Surface Metrology

Optical profilometers and confocal microscopes now measure surface roughness, texture, and form on medical CNC plastic parts without contact, preventing contamination while providing comprehensive 3D surface characterization. These systems document surface finish quality for regulatory submissions and quality management.

Surface Chemistry Analysis

Portable X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) systems verify surface treatments and cleanliness levels, confirming biocompatibility and contamination control. Integration with manufacturing execution systems enables real-time verification and documentation.

Automated Optical Inspection

AI-powered optical inspection systems identify surface defects, contamination, and post-processing inconsistencies with sensitivity exceeding human visual inspection. Machine learning algorithms trained on medical device quality standards flag potential issues for review, reducing escaped defects while accelerating throughput.

Regulatory Considerations and Documentation

Innovations in post-processing must align with regulatory requirements. Modern systems integrate comprehensive documentation:

Process validation protocols: Automated data collection demonstrating process consistency and capability meeting FDA and international regulatory standards.

Traceability systems: Unique part identification linked to specific post-processing parameters, materials, and verification results enabling complete traceability for regulatory audits.

Change control management: Digital systems documenting post-processing modifications, ensuring proper validation and regulatory notification when processes change.

Selecting CNC Machining Parts Suppliers with Advanced Post-Processing

When sourcing medical CNC machining services, evaluating post-processing capabilities proves as critical as assessing machining competence. Key considerations include:

Cumplimiento de la normativa: ISO 13485 certification and FDA registration demonstrate quality system maturity for medical device manufacturing including post-processing controls.

Process capabilities: Verify specific post-processing technologies align with your component requirements—sterilization resistance, optical clarity, biocompatibility enhancement, or antimicrobial properties.

Validation documentation: Request process validation protocols, demonstrating post-processing consistency and capability for your applications.

Material expertise: Confirm experience with your specific medical-grade plastics and knowledge of appropriate post-processing techniques for those materials.

Quality systems: Assess inspection equipment and documentation practices ensuring post-processing verification and regulatory traceability.

Conclusión

Innovations in post-processing techniques for medical CNC plastic parts have expanded what’s possible in medical device manufacturing, enabling components with enhanced biocompatibility, improved sterilization resistance, optimized surface properties, and superior functional performance. From robotic polishing and plasma treatments to antimicrobial surface modifications and stress relief innovations, these advanced techniques transform machined parts into medical devices meeting the industry’s rigorous performance and regulatory requirements.

As medical device complexity increases and regulatory scrutiny intensifies, partnering with CNC machining parts suppliers offering cutting-edge post-processing capabilities becomes increasingly important. The convergence of precision CNC machining medical components with innovative finishing techniques creates opportunities for medical devices with improved patient outcomes, extended service lives, and enhanced safety profiles. Understanding these innovations empowers medical device manufacturers to specify appropriate treatments, evaluate supplier capabilities effectively, and ultimately deliver superior medical products serving patient health and safety.

Preguntas frecuentes

¿Cuál es la forma más segura de alisar accesorios de ABS impresos en 3D para uso médico?

El alisado por vapor en una cámara sellada elimina las crestas sin polvo de lijado; seguido de un enjuague compatible con rayos gamma.

¿Afecta el tratamiento con plasma a la resistencia mecánica?

No; el plasma sólo cambia los nanómetros superiores, dejando intacta la resistencia del grueso.

¿Se pueden volver a aplicar los nanorrevestimientos después de renovar los aparatos?

Sí, siempre que la capa original se elimine con plasma suave o disolvente, y después se vuelva a aplicar y curar.

¿Cómo puedo saber si mi ventana PET necesita un revestimiento duro UV?

Si la pieza se somete a repetidas limpiezas desinfectantes o a la exposición al láser, un recubrimiento UV con clasificación 3H evita el empañamiento y los arañazos.

¿Son más difíciles de esterilizar las superficies texturizadas por láser?

No si las ranuras son submicrónicas; de hecho, reducen la carga biológica al limitar las zonas planas de aterrizaje para los microbios.