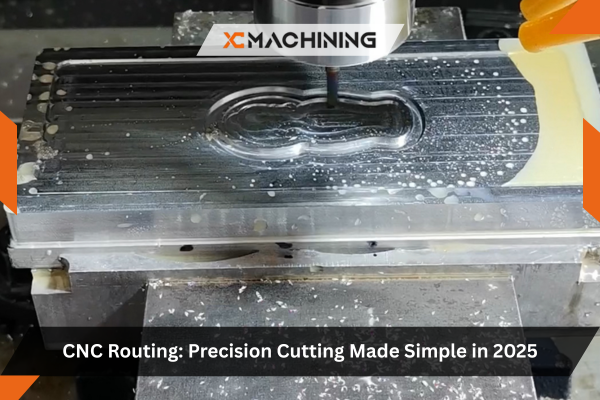

Laser cutting is known for its high accuracy, achieving tolerances as tight as ±0.1 mm, depending on the material and thickness. The accuracy of laser cutting is one of its most significant advantages, as the process can be used to create very detailed parts and fine features that would be difficult or impossible to achieve with other methods. The narrow laser beam allows for small, precise cuts, and the automated nature of the process ensures consistent results throughout a production run. For applications requiring tight tolerances and high repeatability, laser cutting is an excellent choice.