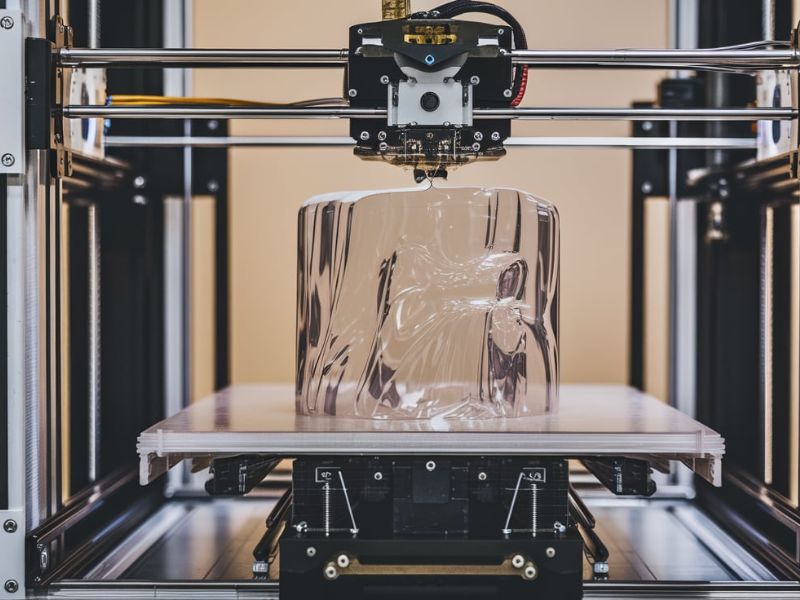

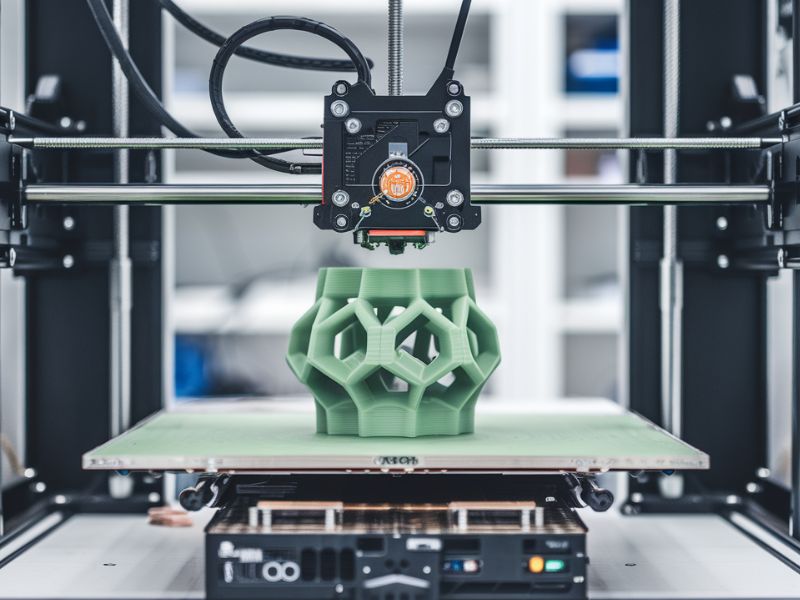

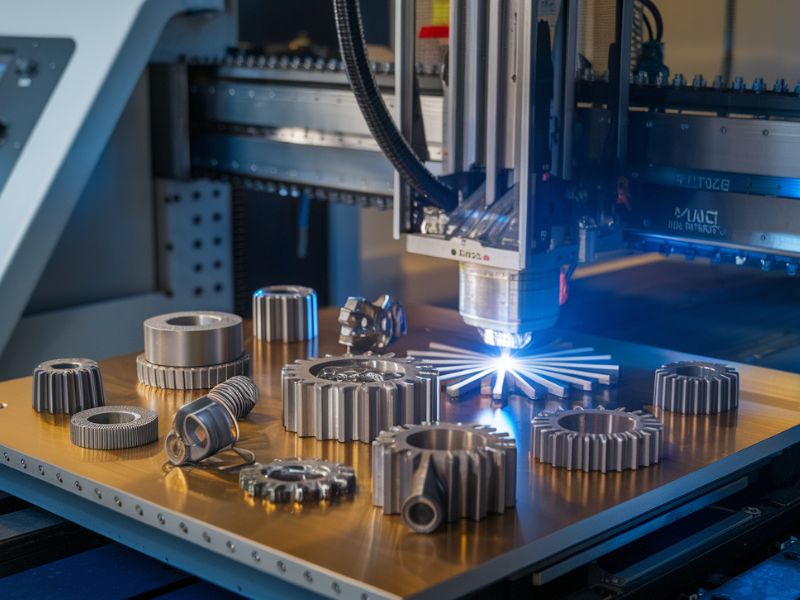

3D printing encompasses various technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS). Each method uses different materials and processes to create objects, offering distinct benefits such as speed, precision, and material versatility. Choosing the right technology depends on the part’s complexity, material requirements, and production volume.