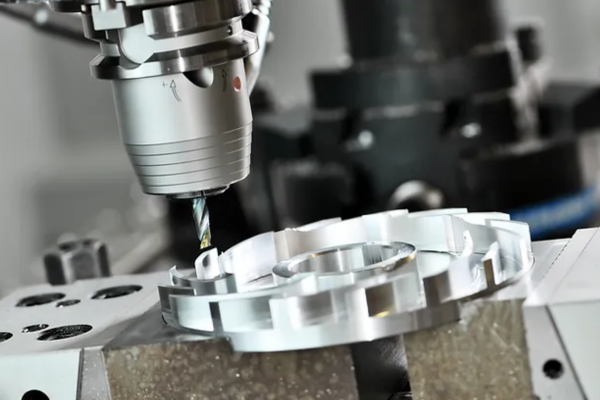

There are several types of surface finishing processes available, including polishing, which gives parts a smooth, high-gloss finish; anodizing, which enhances the corrosion resistance of metals like aluminum; brushed finishes, which add a uniform texture to metal parts; powder coating, which provides a durable, weather-resistant finish; and deburring, which removes sharp edges and rough spots from the part. Each process serves a different purpose depending on the material, application, and required finish.