Brushed finishes vary in texture, grain direction, and coarseness. Each type creates a distinct aesthetic and functional effect, making it important to choose the right style based on application requirements.

Straight-Grain Finish

The No. 4 straight-grain finish is one of the most recognized brushed patterns, widely used on appliances, elevators, and consumer electronics. It forms long, parallel lines created by consistent motion across the surface. This finish offers a clean, modern appearance and is excellent for parts that require a professional, uniform look.

Cross-Brushed Finish

Cross-brushing combines horizontal and vertical abrasion patterns to create a textured, multi-directional grain. This finish is often used for industrial components or artistic applications where a unique aesthetic is required. It also helps hide surface imperfections more effectively than single-direction brushing.

Satin Finish

A satin brushed finish is finer and smoother than standard brushing. It uses higher-grit abrasives to achieve a soft, elegant matte surface. Satin finishes reduce glare and reflectivity, making them ideal for consumer goods, interior vehicle parts, and high-end decorative hardware. XC Machining produces satin finishes that maintain uniformity even on complex geometries.

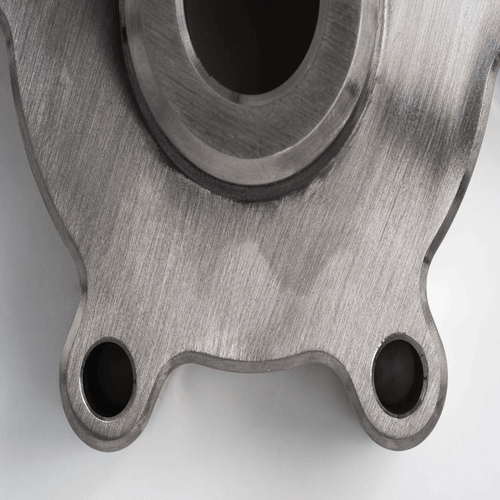

Coarse Brush vs Fine Brush Options

The coarseness of the grain can be adjusted based on application needs. Coarse brushing produces bold, deeper lines suited for rugged or industrial parts, while fine brushing creates delicate, subtle lines for premium visual aesthetics. XC Machining controls abrasive grit, feed direction, and brushing pressure to deliver precise grain texture.

Custom Grain Designs for Branding or Premium Appearance

Some projects require unique visual patterns for branding or luxury aesthetics. XC Machining can create diagonal, circular, randomized, or flowing grain directions depending on design specifications. These custom textures elevate the appearance of CNC-machined parts used in consumer electronics, jewelry, architectural panels, and specialty product lines.