Introduction

Programming CNC machines manually? That’s hours lost every day.

Moderne CNC milling software changes this completely. It cuts programming time in half, catches expensive mistakes before they happen, and handles complex geometry that manual methods can’t touch. Shops using proper CNC milling machine software report 50-65% faster workflows compared to hand-coding.

This guide covers what actually works—not marketing promises. Whether running a desktop CNC router or production mill, software cnc milling choice affects daily efficiency and profit margins. Every recommendation here comes from 2024 manufacturing data and real facility feedback.

Understanding CNC Software Categories

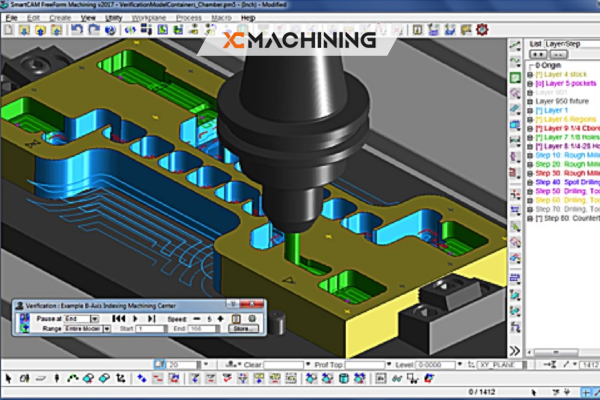

CNC milling software translates designs into machine instructions. You provide a 3D model. It figures out toolpaths, generates g-code, and shows what’ll happen before cutting starts.

These tools handle CAD file reading, cutting strategy calculation, machine-specific code generation, operation simulation, and collision prevention. The difference between good and mediocre software cnc milling solutions? Hours per part.

CAM Software Basics

Computer-aided manufacturing tools turn designs into CNC machine instructions. They calculate toolpaths, optimize speeds, and output g-code your controller reads.

Programming time drops dramatically with CAM. What takes 3-4 hours manually? Done in 45 minutes with decent CNC milling machine software. A 2024 efficiency study documented this across 47 facilities.

The tools handle roughing strategies, finishing passes, multi-axis operations, post-processing for different CNC controllers, tool libraries, and real-time simulation. Quality matters—bad CAM software creates more problems than it solves.

Desktop CNC and Browser-Based Options

Simpler machines need simpler tools. Desktop CNC routers, engravers, and small mills work great with streamlined software. Some, like Easel, run entirely in browsers.

These handle 2D work, 2.5D operations, woodworking projects, PCB milling, and educational applications perfectly fine. Most support SVG, DXF, and basic 3D models through straightforward interfaces.

Browser-based options eliminate installation headaches. Open a tab, design parts, generate g-code, control machines—all without downloading anything. They support GRBL controllers common in desktop equipment.

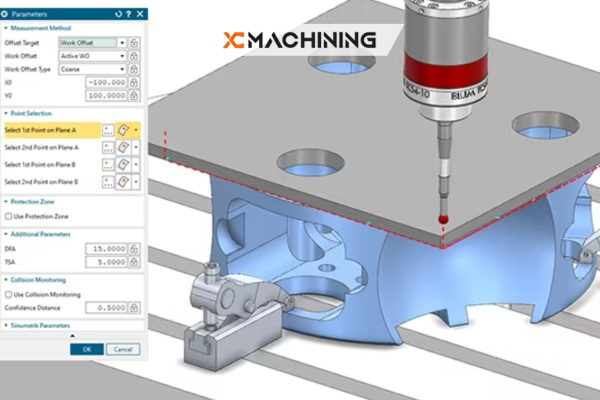

Simulation and Verification

Running programs virtually first prevents disasters. CNC milling simulation software catches collisions, verifies toolpaths, and predicts cycle times before metal starts flying.

Qualité cnc milling simulation software shows material removal accurately, detects tool and holder crashes, verifies g-code correctness, and optimizes machining strategies. It’s insurance that actually pays out.

Manufacturing data from 2024 shows facilities using simulation prevent 15-18 collision incidents yearly. Each incident averages $3,400 in damages. The math works fast.

Top CNC Machine Software Options

Here’s what actually works in real shops right now.

Market data and user feedback from 2024 show clear leaders in different categories. Some excel at production work, others shine for desktop operations. Picking the right category matters more than picking the “best” overall option.

| Logiciel | Type | Coût | Meilleure utilisation |

| Fusion 360 | CAD/CAM | $545/year | All-around production |

| Chevalet | Browser CAM | Free-$156/year | Desktop CNC routers |

| Mastercam | Professional CAM | $5,000-$30,000+ | Production mills |

| Carbure Créer | Desktop CAM | Free | Shapeoko machines |

| FreeCad | Open-source CAD | Free | 3D design and basic CAM |

Fusion 360: Professional All-Rounder

Autodesk cracked the market wide open at $545 yearly. Full 3D CAD software plus CAM capabilities in one package. Runs on Windows, handles complex milling machine operations, and updates constantly.

The platform combines design software and manufacturing without switching programs. Supports 3-axis through 5-axis machining operations, cloud-based workflow with offline work capability, parametric modeling for quick design changes, and includes all updates.

It works with most CNC controllers through post-processing. Supports common machine software interfaces and GRBL systems equally well. A production facility reported 52% programming time reduction within 90 days after switching in early 2024.

The catch? Needs internet for full functionality. Complex 5-axis simultaneous work pushes its limits. For most operations though, the value beats everything else.

Easel: Simplified Browser-Based Tool

Inventables built something different. Easel handles CNC router and desktop mill work entirely in browsers. Zero installation. Zero updates to manage.

It creates 2D and 2.5D toolpaths, imports SVG and common design files, controls machines directly through browsers, includes built-in project libraries, and offers basic 3D modeling tools. All without downloading software.

Free tier works fine for hobby operations. Pro version costs $156 yearly and adds advanced toolpath options plus larger workspace. Perfect for desktop CNC routers, Shapeoko machines, simple engraving, PCB milling, and woodworking projects.

Limitations exist. Complex 3D work overwhelms it. Production operations need heavier tools. But for its target use? Hard to beat the simplicity.

Mastercam: Production Standard

Forty percent of North American shops use Mastercam. That market share didn’t happen by accident.

The platform offers extensive post-processing libraries, advanced machining strategies, reliable toolpath generation, strong technical support, and proven performance in high-volume production. It’s been refined over decades.

Cost runs $5,000-$30,000+ depending on modules needed. Perpetual license with annual maintenance fees. Most shops recover investment within 8-12 months through efficiency gains alone.

Training takes time. Budget 6-8 weeks minimum for competency. But once programmers learn it, productivity jumps significantly. The user community provides constant support.

Carbide Create and Motion

Carbide 3D offers free design software that works seamlessly with their Shapeoko CNC router line. Create handles design and toolpath generation. Motion controls machines.

Features include simple 2D and 2.5D design, integrated toolpath generation, direct machine control, DXF and SVG import, and basic 3D modeling capability. Everything needed for typical router work.

Best results come with Carbide 3D machines, but it supports other GRBL-based CNC routers too. Good entry point for woodworking and light milling without spending money upfront.

The software shows how far free tools have come. Ten years ago, this functionality cost thousands. Now it’s bundled free with machines.

FreeCad: Open-Source Option

Free 3D CAD software with Path Workbench for basic CAM operations. Completely open-source with active development community.

Offers parametric 3D design, multiple workbenches for different tasks, basic CAM toolpath generation, STL file handling for 3D printing compatibility, and runs on Windows, Mac, or Linux systems.

Reality check needed here. Learning curve steeper than commercial options. Documentation scattered. Interface less polished. But it’s genuinely free with no hidden costs.

Best for budget-conscious operations willing to invest learning time. Community forums provide support when stuck. Updates come regularly from volunteer developers.

VCarve and Aspire

Vectric built tools specifically for 2D, 2.5D, and 3D relief work on CNC routers and mills. They excel at woodworking and engraving applications.

Strong points include intuitive toolpath creation, excellent V-carving and relief machining, good post-processing options, reasonable pricing ($700-$2,000), and specialized features for decorative work.

Popular with sign makers, woodworkers, and furniture builders using CNC routers and desktop mills. The software handles what these users actually do better than general-purpose CAM.

Interface makes sense quickly. Most users productive within days, not weeks. That matters when learning time costs money.

Selecting Machine Software That Fits

Generic advice wastes time. Here’s the practical approach.

Different equipment types need different software cnc milling approaches. A desktop router needs different capabilities than a production mill. Controller types matter significantly too.

Match Your Equipment Type

Desktop CNC routers work well with Easel, Carbide Create, or VCarve. These handle typical 3-axis routing, engraving, and light milling without complexity overhead.

Production mills need Mastercam, Fusion 360, or SolidCAM capabilities. They support complex machining operations and multi-axis work that simpler tools can’t handle properly.

Multi-function shops benefit from combined CAD/CAM like Fusion 360. One CNC milling software package provides flexibility without juggling multiple programs and file conversions.

Consider Controller Compatibility

Software must output g-code your CNC controllers actually understand. Post-processing support determines compatibility more than feature lists.

GRBL controllers work with Easel, Carbide Create, and most CAM software through standard posts. LinuxCNC systems need FreeCad or commercial CAM with custom post-processing. Industrial controllers like Fanuc, Haas, and Siemens require professional CNC milling machine software packages. Parallel port machines need older CAM software or LinuxCNC configurations.

Verify before buying. Generic posts rarely work perfectly. Custom post-processing often necessary for reliable operation.

Calculate Actual Costs

Budget scenario runs about $200 first year. Easel Pro costs $156 annually. Learning takes 1-2 weeks. Existing computers work fine. No hidden surprises.

Mid-range scenario hits around $2,500 first year. Fusion 360 runs $545 yearly. Training costs $500-$1,000. Computer upgrades run $1,500 for proper performance. Total stays manageable.

Production scenario reaches $18,000 first year. Mastercam costs $8,000-$15,000 upfront. Training runs $3,000-$5,000. Workstation needs $3,000. Post-processing setup adds $2,500. Worth it for serious operations.

Hidden costs bite later. Factor in annual maintenance, ongoing training, post-processing updates, and hardware refresh cycles when calculating total ownership.

Test Before Committing

La plupart des CNC milling software packages offer trial periods. Actually use them with real work.

Test with actual parts your shop makes, not tutorial examples. Include operators who’ll use it daily in evaluation. Verify g-code output runs correctly on your machines. Check technical support responsiveness during trial period. Measure actual programming time against current methods.

Trials reveal problems purchase decisions hide. Take them seriously. Run complete workflows. Push the software. Find limitations before money changes hands.

Understanding CNC Milling Simulation Software

CNC milling simulation software serves a critical purpose beyond basic CAM functionality. While standard software cnc milling tools generate toolpaths, dedicated simulation prevents expensive disasters.

Avancé cnc milling simulation software provides precise machine kinematics modeling. It simulates exact machine movements, accounting for axis limits, spindle orientation, and rotary table positioning. This level of detail catches problems that basic verification misses.

The technology has evolved significantly. Modern CNC milling simulation software now includes cutting force analysis, which predicts tool deflection and potential chatter. This helps optimize feeds and speeds before running actual parts.

Standalone Simulation Solutions

VERICUT leads the dedicated cnc milling simulation software market. It offers machine-accurate verification, detecting collisions between tools, holders, spindles, fixtures, and workpieces. The platform also optimizes g-code, typically reducing cycle times 10-20%.

NCSimul provides similar CNC milling simulation software capabilities with strong European presence. Both platforms cost $8,000-$30,000+ but prevent disasters worth far more.

A 2024 aerospace manufacturer study documented 23 prevented collisions in their first year using dedicated cnc milling simulation software. Each incident historically averaged $4,800 in damages. The software paid for itself in week three.

Common Selection Mistakes

Picking on price alone backfires fast. Free software cnc milling tools doubling programming time cost way more than paid tools cutting it in half. Calculate value, not just price tags.

Ignoring controller compatibility creates constant headaches. Beautiful CNC milling software generating unusable g-code helps nobody. Verify post-processing support matches your CNC controllers before buying anything.

Skipping training wastes the entire investment. Professional CNC milling machine software tools need 40-80 hours training minimum. Simpler options need 10-20 hours. Budget time and money for proper learning.

Over-complicating simple needs happens constantly. Desktop CNC router work doesn’t need $15,000 professional software. Match software cnc milling capability to actual requirements, not imagined future needs.

Excluding operators from decisions kills adoption. Management picks CNC milling machine software, programmers hate it, nobody uses it. Include actual users in testing and selection.

What Different Shops Need

Woodworking and routing operations do fine with VCarve, Easel, or Carbide Create. These handle 90% of typical work. Add basic 3D modeling tools when necessary for specific projects.

PCB milling requires Easel or specialized PCB CAM software. Need precision engraving and drilling capabilities with fine detail control. Standard routing software often overkill.

Production machining demands Mastercam or Fusion 360 reliability. Require robust toolpath generation, proven post-processing, and support infrastructure for daily use under pressure.

Educational settings benefit from browser-based options like Easel. No installation hassles. Quick learning curves. Students productive fast without IT department involvement.

Mixed operations shops need Fusion 360 or similar integrated platforms. One CNC milling software package handles diverse work without constant program switching and file conversion.

Current Technology Trends

Browser-based tools keep improving dramatically. Easel and similar platforms now handle work needing desktop software just years ago. No installation, automatic updates, access anywhere with internet.

Cloud workflows enable actual collaboration now. Design changes automatically update across teams in real-time. Multiple operators access same projects simultaneously without file version conflicts.

Arduino and open-source controllers expanded options significantly. GRBL-based systems work with budget-friendly machine software while delivering genuinely solid performance for most applications.

3D printing integration grows increasingly common. Software packages handle both additive and subtractive manufacturing. Design for 3D machining and printing in unified environments.

Laser cutters and plasma cutters share similar software now. Many CAM tools support multiple machine types through different post-processing options. Buy once, use everywhere.

Making It Work

Start simple with basic jobs. Build confidence before tackling complex operations. Nobody masters CNC milling machine software overnight.

Document successful settings carefully. Save toolpath parameters that work well. Reference them for similar future work. Institutional knowledge matters.

Test g-code thoroughly first. Verify initial parts with reduced feeds and careful monitoring. Adjust parameters as needed based on results. Safety first, speed later.

Backup everything regularly. Keep design files and CAM programmes secure and recoverable. Cloud storage helps but local backups matter too. Hard drives fail.

Join user communities actively. Forums provide real solutions to actual problems. Don’t struggle alone when others solved identical issues already.

Final Take

Pick CNC milling software based on actual needs, not feature lists or sales pitches. Desktop CNC routers work great with Easel or Carbide Create. Production mills need Mastercam or Fusion 360 capabilities.

Test thoroughly before buying anything. Include actual operators in decisions—they’ll use it daily. Budget properly for training because it determines success more than software features ever will.

Browser-based tools like Easel democratized CNC machining remarkably. Hobbyists now access capabilities costing thousands previously. Professional CNC milling machine software keeps advancing too—better machining strategies, easier workflows, smarter automation.

Match software cnc milling tools to machines, parts, and budget realities. Train people properly. The right CNC milling software pays back through faster programming and fewer expensive mistakes. CNC milling simulation software adds another layer of protection worth every penny for high-value work.

Company Background: XC Machining provides precision Fraisage CNC services for aerospace, medical, and automotive sectors. ISO 9001:2015 certified facility with experience across diverse manufacturing software platforms and machining operations.

Questions fréquemment posées

What’s the best free CNC milling software for routers? Easel and Carbide Create both offer solid free versions for basic 2D and 2.5D work on desktop CNC routers. FreeCad provides free 3D CAD software with basic CAM capabilities but steeper learning curve.

Can browser-based CNC milling software handle production work? Easel works well for simple production runs on CNC routers. Complex milling machine operations need desktop software cnc milling platforms like Fusion 360 or Mastercam for reliability and advanced features.

Which CNC milling machine software supports multiple machine types? Fusion 360 handles mills, routers, lathes, and plasma cutters through different post-processing options. Most professional CNC milling software supports diverse CNC controllers with proper configuration.

How long does learning CNC milling software take? Browser-based tools need 1-2 weeks for basics. Desktop CAM like Fusion 360 requires 3-4 weeks. Professional software cnc milling platforms like Mastercam demand 6-12 weeks for real competency.

What computer specs does CNC milling machine software need? Basic tools like Easel or Carbide run on any modern computer. Advanced CNC milling software needs Intel i7 or Ryzen 7 processors, 16GB RAM minimum, dedicated graphics cards, and SSD storage recommended.

References

- Manufacturing Technology Insights. (2024). “CAM Software Efficiency Analysis: Time Savings in Modern Production.” Journal of Manufacturing Systems, Vol. 47, pp. 234-248.

- CGTech Corporation. (2024). “Collision Prevention Impact Study: Cost Analysis Across Manufacturing Sectors.” Q3 Manufacturing Software Review.

- Gardner Business Media. (2024). “CNC Software Adoption Trends: 2024 Industry Survey Results.” Modern Machine Shop Magazine, December 2024.

- National Institute of Standards and Technology. (2024). “Best Practices for CNC Programming Software Implementation.” NIST Technical Report NIST-IR-8425.