Bead blasting is a precision surface-finishing technique where fine spherical media, glass or ceramic beads are propelled onto the surface of a part to smooth it, clean it, or create a uniform matte texture. XC Machining uses controlled bead blasting systems to achieve consistent, repeatable results across metals and plastics.

Media Selection Based on Material & Finish

The process begins with choosing the appropriate bead media. Glass beads create a soft matte finish, ceramic beads are used for tougher metals, and plastic media are selected for delicate or thin-walled components. XC Machining evaluates material hardness, geometry, and the desired texture before selecting the ideal media.

Pressurized Delivery System

The blasting machine uses compressed air to accelerate the beads toward the surface. The pressure between 40–80 psi depending on the material—is precisely controlled. Lower pressure is used for plastics and thin metals, while higher pressure is reserved for durable alloys. XC Machining calibrates pressure settings for perfect consistency.

Surface Impact & Micro-Peening Action

As the beads strike the surface, they create millions of tiny, evenly distributed impacts. This micro-peening process smooths sharp edges, removes light burrs, and eliminates machining marks without removing significant material. The spherical shape of beads ensures non-destructive finishing, unlike angular abrasives.

Coverage & Pattern Control

Technicians maintain consistent nozzle movement and angle to ensure uniform coverage. Overlapping passes produce a balanced matte texture with no streaks or over-blasted zones. XC Machining trains its finishing team to use controlled sweeping motion for evenness across flat, curved, and complex surfaces.

Final Cleaning & Quality Inspection

After blasting, parts are cleaned to remove residual media using compressed air, ultrasonic cleaning, or rinsing (for metals). XC Machining inspects each part for uniformity, protected areas, and surface quality before moving to final packaging or post-processing (such as anodizing or coating).

What Surface Texture Does Bead Blasting Create?

Bead blasting is valued for producing elegant, subtle, and uniform surface textures that enhance both aesthetics and functionality. The texture depends on bead size, pressure, and the hardness of the base material.

Soft, Uniform Matte Finish

The most recognizable result of bead blasting is a smooth matte surface that removes shine and glare. This texture is popular for consumer electronics, aerospace housings, medical tools, and premium aluminum components. XC Machining achieves a perfectly consistent matte appearance, even on complex geometries.

Satin-Like Texture With Fine Diffusion

Bead blasting creates a gentle satin surface that diffuses light evenly. Unlike coarse sandblasting, bead blasting does not bite into the metal aggressively. This makes it ideal for cosmetic parts where a refined, premium feel is essential.

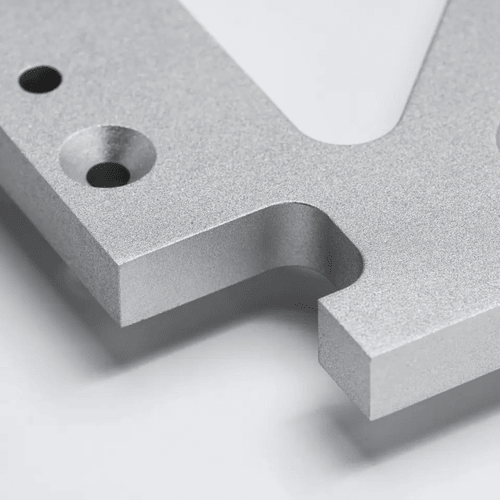

Smooth Surface With Reduced Machining Marks

The process eliminates light tool marks, minor scratches, and small burrs created during CNC machining. While it does not remove deep scratches, it dramatically improves the overall surface quality. XC Machining often uses bead blasting as a pre-anodizing treatment for aluminum to ensure clean, uniform color absorption.

Micro-Texture With Controlled Roughness (Ra)

Bead blasting typically results in surface roughness values between Ra 1.5–3.5 µm depending on bead size and pressure. Smaller beads create smoother surfaces, while larger beads make slightly more textured finishes. XC Machining adjusts media size and blasting parameters based on functional and cosmetic requirements.

Blended Surface Appearance With No Sharp Edges

Instead of leaving directional scratches, bead blasting blends the surface uniformly in all directions, creating a soft, tactile feel. Edges become slightly smoother, improving handling and safety without altering part dimensions significantly.

What Materials Are Suitable for Bead Blasting?

Bead blasting is compatible with a wide range of engineering materials. XC Machining carefully selects bead types and pressures to avoid over-blasting soft materials or damaging precision surfaces.

Aluminum Alloys (6061, 7075, 2024, etc.)

Aluminum responds exceptionally well to bead blasting and produces a beautiful matte texture. It is widely used for aerospace parts, electronic housings, and automotive components. Bead blasting is often followed by anodizing to create clean, uniform coloration. XC Machining uses fine glass beads for optimal results on aluminum.

Stainless Steel (304, 316, 17-4PH)

Stainless steel withstands bead blasting very well and results in a clean satin texture that hides fingerprints and minor imperfections. It is common in medical devices, food equipment, and industrial components. Ceramic beads are often used for harder steels to maintain consistency and avoid embedding.

Titanium (Grade 1–5)

Titanium develops a premium matte finish when bead blasted. The process reduces glare and enhances appearance without compromising corrosion resistance or mechanical strength. XC Machining uses low-pressure, fine beads to maintain tight tolerances on titanium medical and aerospace parts.

Mild Steel, Carbon Steel & Tool Steel

Bead blasting removes light oxidation, machining marks, and scale from steels. However, because steels can rust, blasting is often followed by coating, plating, or painting. XC Machining provides blasting plus post-treatments such as powder coating, black oxide, and galvanizing.

Engineering Plastics (Nylon, ABS, POM, PC)

Certain rigid plastics can be bead blasted to create a uniform matte surface. Soft plastics, however, may deform or absorb media. XC Machining tests each plastic grade to determine suitability before processing.

Materials to Avoid

Highly soft plastics, rubber-like materials, or pre-coated surfaces may not respond well to bead blasting. XC Machining evaluates the design and material to recommend the safest finishing method.