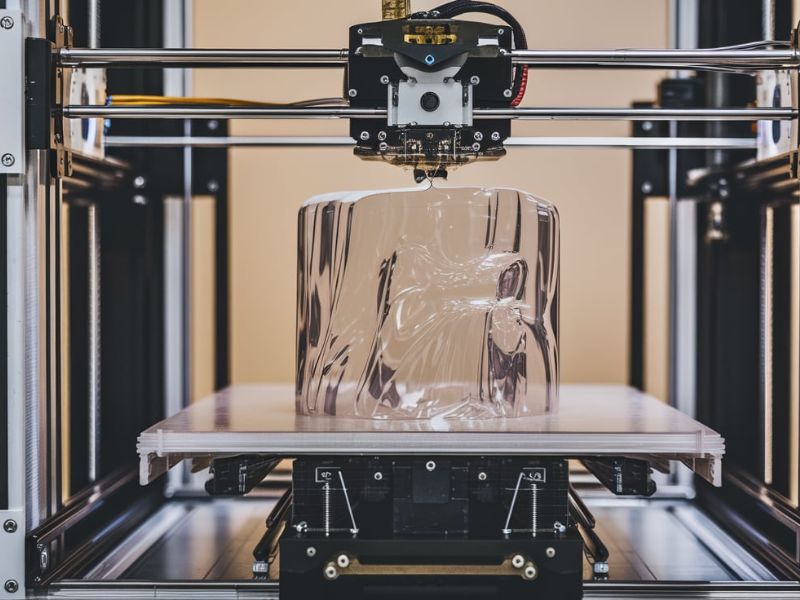

Stereolithography (SLA) is a 3D printing technology that utilizes a laser to cure a liquid resin, layer by layer, to build solid parts with exceptional accuracy. The process begins with the creation of a 3D model that is sliced into thin layers. A laser beam then selectively cures the resin, solidifying it at each layer. The build platform lowers after each layer is completed, and the process repeats until the part is fully formed. SLA is particularly known for its ability to produce parts with extremely fine details and smooth surface finishes, making it ideal for high-precision applications such as dental models, jewelry, and medical devices.