Surface finishing methods can be classified into three categories namely mechanical, chemical and thermal finishing which are designed to attain various surface properties from enhanced aesthetic effects to improved wear resistance.

Mechanical Surface Finishing

Mechanical finishing is based on physical abrasion or deformation to change a surface. It is widely used as a smoothing, texturing agent or base for coatings.

Mechanical methods include:

- Grinding: The high precision and smoothness is realized using abrasive wheels to grind.

- Polishing & Buffing: Produces shine that is reflective like mirrors; you can find this surface in decorative metals and stainless steel.

- Sandblasting: Blasts abrasive media to assist in cleaning and texturing surfaces which enhances the adhesion of coating to surface.

- Shot Peening: Shocks the surface using spherical objects, which are smaller, to strengthen the fatigue capability in parts such as springs and gears.

Chemical Surface Finishing

Chemical finishing involves a reaction between the surface of the material and aqueous solutions to modify the properties of corrosion properties, adhesion, or appearance.

Chemical methods include:

- Pickling: Dissolves oxides, scale and contaminants of metals with acid based solutions.

- Passivation: Improves resistance to corrosion, by improving the protective layer of oxidation particularly on stainless steel.

- Electropolishing: Melt away microscopic prominences to impart a microscopically smooth shiny surface which enhances hygiene and aesthetics.

- Conversion Coatings: It includes processes such as phosphating and chromating, which form a corrosion resistant base on which painting can be done.

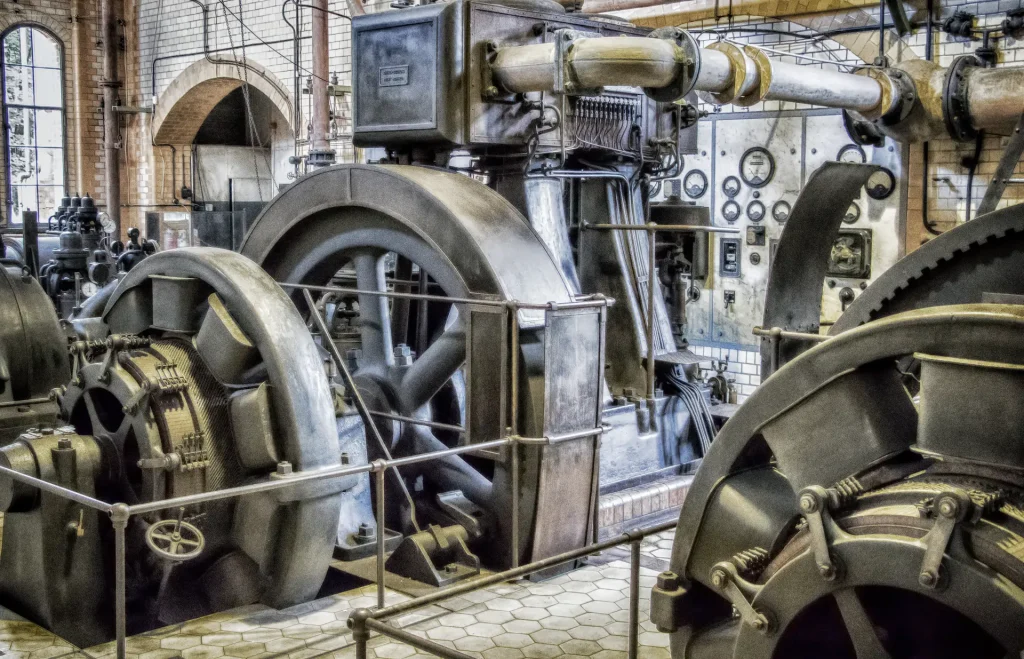

Thermal Surface Finishing

Heat treatment is applied and formed by means of defined warmness to alter the micro structure of a surface, or use specialized covering. These may greatly increase hardness, wear resistance, thermo-stability.

Thermal methods include:

- Thermal Spraying: It is used to deposit molten or semi-molten material to a surface to form a layer of protection, in turbines and aerospace parts.

- Heat Treatment: It modifies surface strength and hardness and does not modify core material characteristics.

- Laser Surface Treatment: It hardens or manipulates the surface layer using targeted laser beams with utmost accuracy.

- Plasma Coating: Uses ionized gas to deposit high-density, high-performance unlimited depositions of coatings suitable in extreme conditions.

What Are the Common Challenges in Surface Finishing And How Are They Solved?

Surface finishing plays a crucial role in product quality and the undertaking of the same is faced with technical, environmental and economic challenges each with a need to find smart and innovative solutions to address them.

Achieving Consistent Quality

Challenge: Gloss, thickness and surface texture are hard to control and keep equal on high-volume runs, particularly where very complex shapes and different materials are used.

Solution: Sensor driven automated finishing systems that are AI guided, give consistent results and statistical process controls keep deviations to within tight tolerances.

Environmental and Regulatory Compliance

Challenge: The use of hazardous chemicals, extensive use of water, emission of VOCs using traditional processes make them impossible to comply with the contemporary environmental standards.

Solution: Ultra clean chemistries, closed loop water recycling and low-emission technology such as powder coating, can enable the most stringent environmental regulations as well as minimizing waste.

Managing High Energy and Resource Costs

Challenge: Power-heavy solutions like thermal spraying and furnace finish, increase operational costs of large scale facilities by a very large degree.

Solution: Energy recovery systems, fine temperature control and implementation of laser-based finishing eliminate power consumption and decreased cost of the entire process.

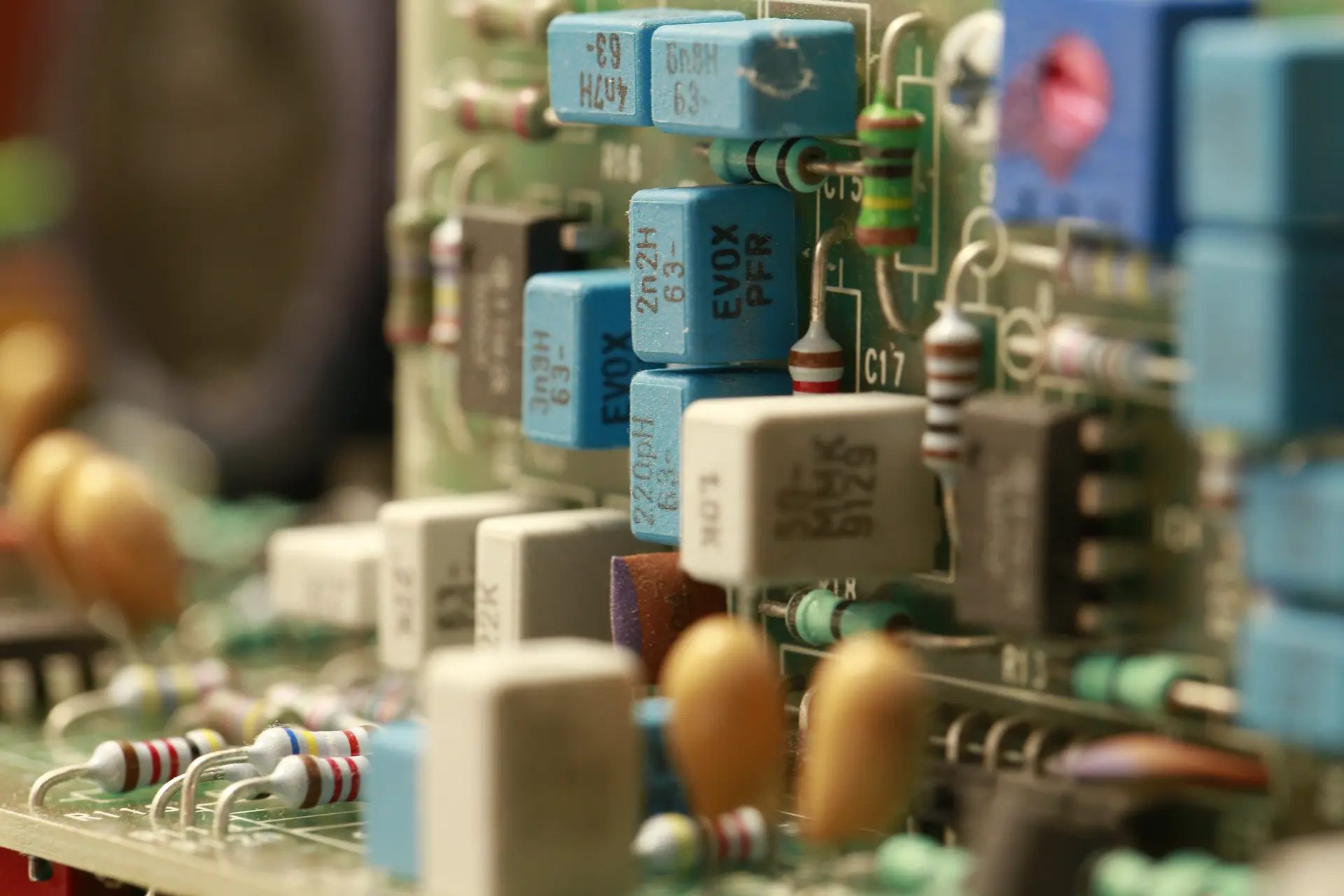

Dealing with Complex Parts

Challenge: Microminiaturization or delicate components calls for the most serious processes of control that may not lead to structural repairs during finishing.

Solution: Use non-abrasive methods such as electropolishing and plasma cleaning as well as robotic micro-processing that provide non destructive finishes without altering the integrity of the part.

Balancing Speed with Quality

Challenge: Meeting high production demands while maintaining superior surface quality can strain resources and workflow efficiency.

Solution: Inline finishing systems and digital twin simulations can speed up the process by reducing lead times and at the same time provide consistent defect-free finishes.