Aluminum extrusion is a process used to melt down dense metal billets into the accurate continuous profiles via pressing and heating and refined shaping methods.

Billet Preparation

The procedure begins by using aluminum billets which are metallic cylindrical blocks of aluminum that are scrutinized and cut into the stipulated length. These billets are frequently subjected to a process called homogenization, whereby the heat treatment balances out the distribution of alloy in the structure. This process enhances the mechanical properties of the metal, making it strong and consistent and easily flowing through the extrusion process.

Preheating

The next step is to heat the billet to a certain degree i.e. against 800degrees F to 925 degrees F (427degrees C to 496degrees C ) in case of hot extrusion. This mutes the aluminum but does not melt it making it push easier through the die. At this step proper temperature is important to avoid defects on the surface and to have extrusions of the same quality.

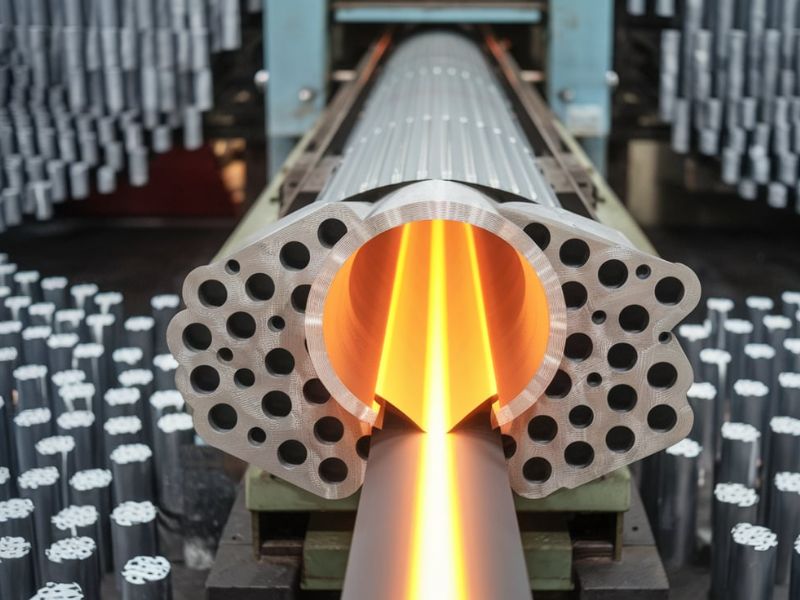

Extrusion

The hot billet gets put into the extrusion-press and under a hydraulic ram there is a tremendous pressure between 500-9000 tons which forces the billet through a profiled steel die. The aluminum runs through and assumes the exact shape of the die opening and creates parts with constant cross-sections.

Refroidissement

After the aluminum profile is pushed out of the die, it is almost red hot, and must be rapidly cooled or the shape and qualities will be lost. Usually this is accomplished by the use of air fans or water quenching. Controlled cooling keeps the metal mechanically strong and at the same time warp-free or dimensionally precise.

Stretching and Cutting

When cooled the profiles extruded may be off centre with slight twists and bends caused as a result of release of pressure. They are straightened by passing through special equipment in an attempt to straighten and relax the tensions inside. The material is then cut into standard lengths or as per the requirements of the concerned customer.

Finition

Finally, aluminum profiles are subjected to coating and finishing processes that improve performance and appearance, durability. Common methods are anodizing to produce corrosion protection, powder coating to produce a color finish and precision machining to produce exact sizes. This process makes the product ready to use for its intended application, including construction frames and in automobile parts.

What are The Advantages of Aluminium Extrusion?

Aluminum extrusion fulfills high strength-to-weight ratio components and has infinite design capabilities. It is a dependable, affordable, industry-standard from construction to aerospace.

Lightweight with High Strength

Compared to aluminum, extrusions can be up to 66 percent lighter than steel and still have the ability to move great weight through it. It is particularly useful in industries where weight loss can increase fuel efficiency and performance such as automotive and aerospace without decreasing safety, such as on an aircraft.

Résistance à la corrosion

This aluminum automatically develops a coating of thin oxide that makes its surfaces resistant to rust and corrosion, even within extreme conditions. This qualifies extruded profiles to be used in outdoor structures, marine and architectural uses, which most often need minimal to no protective covering on them.

Rapport coût-efficacité

Extrusions are made to near-net shape hence they have little or no machining. This minimizes dissipation of materials and cuts down the costs of production. Moreover, extrusion dies are cheaper than molds required by casting or injection molding processes and the technique is not only economical when it comes to a small number of products characterized by a large production run.

Excellent Thermal and Electrical Conductivity

Aluminum extrusions have good heat and electricity-carrying capacity and are also excellent in use as heat sinks, bus bars, and electronic cases. Some alloys can approach 60 percent the conductivity of pure copper with much lighter weight and greater ease of working.

100% Recyclable Without Property Loss

Aluminum can be recycled any number of times without experiencing a loss of its mechanical or physical properties. Recycling of aluminum consumes 95 percent less energy compared with the manufacture of aluminum using raw material, hence extrusions are a sustainable option in times when environmental restrictions are on the rise.