In the world of additive manufacturing, Fused Deposition Modeling (FDM) is one of the most widely used and versatile 3D printing technologies.

At XC Machining, we specialize in offering FDM 3D printing services that help businesses turn their ideas into tangible, functional parts. Whether it’s for rapid prototyping, custom parts production, or low-volume manufacturing, FDM 3D printing provides an efficient and cost-effective solution for industries across the board.

What is FDM 3D Printing?

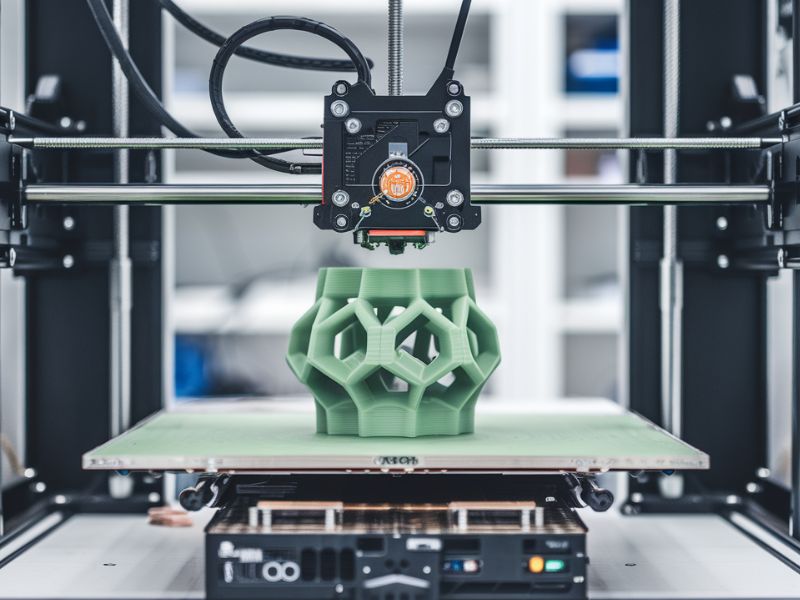

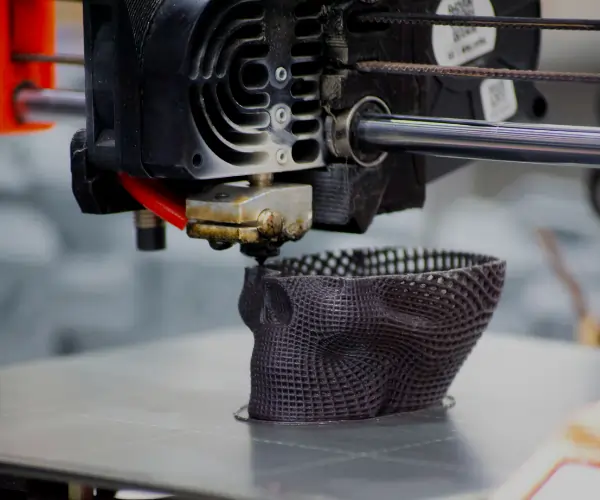

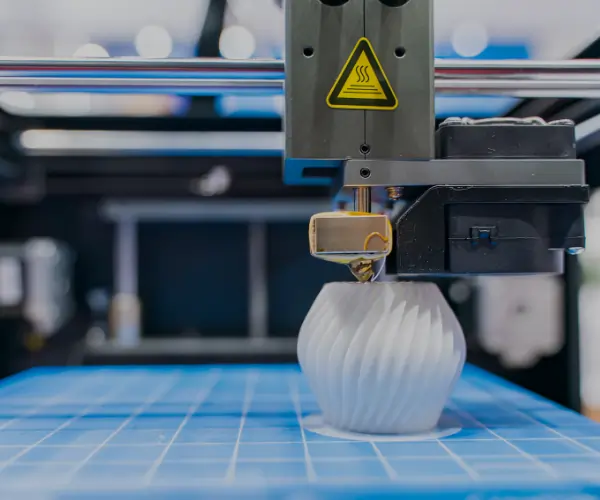

Fused Deposition Modeling (FDM) is a 3D printing process that uses a thermoplastic material, such as ABS, PLA, or PETG, which is heated and extruded through a nozzle to build a part layer by layer.

The material is deposited in thin layers, one on top of the other, and fused together to form a solid object. This process allows for the creation of parts with high accuracy, mechanical properties, and flexibility in design.

FDM is often referred to as “additive manufacturing” because it builds up the part from nothing, layer by layer, as opposed to subtractive manufacturing methods like milling or turning.

Benefits of FDM 3D Printing at XC Machining

Rentabilité

FDM is one of the most affordable 3D printing technologies available, especially for low to medium-volume production. The material costs are relatively low, and there is no need for expensive molds or tooling, making FDM an ideal choice for cost-effective prototyping, small batch production, and custom part manufacturing.

Quick Turnaround Times

The ability to produce parts rapidly is one of the most significant advantages of FDM 3D printing. At XC Machining, we can quickly take your designs from concept to reality, enabling faster product development cycles and reducing time-to-market. Whether you need a single prototype or a series of functional parts, our FDM 3D printing service delivers timely results.

Flexibilité de la conception

FDM 3D printing offers exceptional design freedom, allowing the creation of complex geometries that would be difficult or impossible to manufacture using traditional methods. You can create parts with internal structures, intricate details, or customized features without the constraints of molds, dies, or tooling.

Wide Material Selection

With FDM, you have access to a wide variety of thermoplastic materials that offer various mechanical properties. Whether you need strong and durable parts, flexible components, or parts that are resistant to high temperatures or chemicals, FDM provides a material for nearly every application.

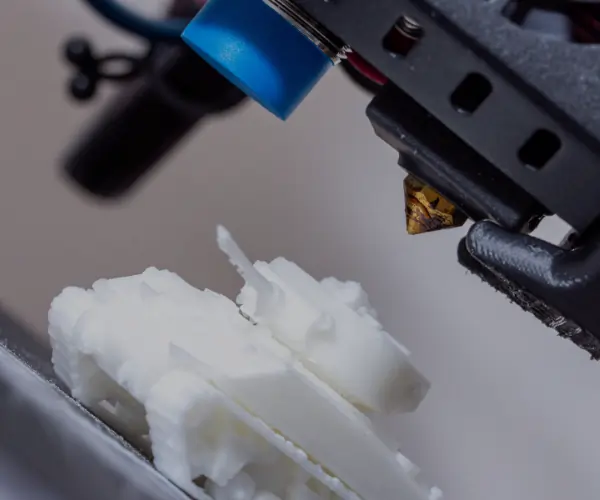

Prototypage rapide

FDM 3D printing is ideal for rapid prototyping, allowing designers and engineers to quickly produce functional prototypes for testing and validation. With FDM, you can test and iterate on designs in real-time, making adjustments based on testing results and customer feedback.

Low Waste Production

Unlike subtractive manufacturing methods, where material is cut away from a larger block, FDM 3D printing only uses the material necessary to create the part, resulting in minimal waste. This is a more sustainable approach to manufacturing, especially for industries focused on reducing their environmental footprint.

Applications of FDM 3D Printing Services

FDM 3D printing is widely used across many industries for a variety of applications, including:

Prototypage

FDM is most commonly used for rapid prototyping, allowing designers to quickly test and refine their ideas. With the ability to iterate designs rapidly and cost-effectively, FDM plays a key role in product development.

Custom Parts Production

FDM technology is perfect for producing custom parts that need to meet specific design criteria or functionality. Whether it’s a custom bracket, housing, or other component, FDM allows for the creation of bespoke parts without the need for tooling or molds.

Small Batch Production

For low-volume or small-batch production, FDM 3D printing is an ideal solution. Since it eliminates the need for expensive tooling, it is an affordable and efficient option for producing small quantities of functional parts, especially when custom features or geometries are required.

End-Use Parts

FDM can also be used to produce durable end-use parts, especially when low-to-medium strength materials are sufficient. Applications in industries such as automotive, consumer goods, and aerospace often leverage FDM for producing functional end-use components.

Get in Touch with XC Machining for Your FDM 3D Printing Needs!

We work closely with our clients to understand their specific needs, offering personalized service and ensuring that each project is completed on time and within budget. Whether you need rapid prototyping, custom parts, or small-batch production, our FDM 3D printing services are designed to meet your unique requirements and exceed your expectations.

Contact us today to discuss your project and discover how we can bring your ideas to life with FDM 3D printing.