China, a manufacturing powerhouse on a worldwide range, has emerged as a major force in the CNC machining industry. Today, China is home to many CNC machining businesses offering rapid prototyping and product parts. These businesses serve both the domestic and international manufacturing sectors.

Although China’s CNC machining has come a long way in its relatively short history, which dates back to the late 1970s and early 1980s, the advancements have been astounding, especially in numerical control systems, spindles, software, servo drives, and tools. Nowadays, Chinese CNC machining has also increased its market share and diversified its product lines to include a variety of machine tools, such as turning centers, milling, drilling, and grinding machines.

Here, we’ll discuss common machining services in China, the numerous benefits of outsourcing to China, and how to find a reliable CNC machine shop.

Common Machining Services You Can Choose in China

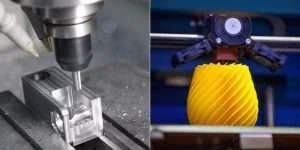

Chinese companies offer a wide range of CNC machining services to various industries. These services include:

CNC Milling

Computer-controlled milling, or CNC milling, is the common machining technique known as milling. Milling involves utilizing a spinning tool to cut materials like wood, metal, or plastic. It is important to note that in CNC milling, the computer controls all parameters, including the feed rate and spindle RPM, the order in which the tools are utilized, and the toolpath for each cutter.

CNC milling can produce intricate forms and features with extreme precision and accuracy. In China, they offer CNC milling services with various materials, including metal alloys, plastics, glass, and ceramics.

CNC Drilling

CNC drilling is a cutting-edge manufacturing method that has changed the manufacturing and production sectors. This process has made it possible for producers to make incredibly precise and repeatable holes in various workpiece materials, including metals and polymers.

Additionally, CNC drilling makes producing numerous hole diameters, depths, and angles possible. Also, most Chinese CNC companies offer drilling services for various markets and industries, including aviation, military, optical communication, healthcare, and more.

CNC Turning

In CNC turning, it rotates the workpiece while employing a cutting tool to create cylindrical or circular shapes. Consequently, with CNC turning services, it is possible to manufacture parts with precise tolerances, accuracy, and excellent surface finish. Companies in China offer turning services for various goods and components, including fixed pin accessories, mechanical apparatus, and automotive equipment.

Wire EDM

With wire EDM, electrical current is transferred between an electrical source and an electrically conductive base material using a thin copper or brass wire. The current generates sparks that can cut materials according to predetermined patterns.

Nonetheless, the material is immersed in deionized water to avoid overheating or warping, enabling clean and accurate cuts. Wire EDM is beneficial for producing incredibly intricate shapes, elaborate designs, and geometric angles that are challenging or impossible to produce using other manufacturing techniques.

Why Outsource CNC Machining Services to China?

Chinese manufacturers have significantly boosted their use of CNC machining tools over the past two decades. As a result, they have emerged as the preferred option for many companies worldwide.

Due to various factors, including low labor costs and low costs of raw materials, China’s CNC machining services, like XinCheng, provide pricing far lower than those of most Western manufacturing enterprises. Here are some benefits of outsourcing CNC machining services to China.

Reduction in Production Cost

The undeniable primary reason and advantage for businesses to outsource to China is that it is cost-effective in many ways. China offers many chances to save money, increase revenues, and gain access to a wealth of local talent in various industries. Having cheaper access to raw materials and finished goods and workers with basic or specialized skill sets are further advantages.

In other words, outsourcing CNC machining to Chinese machining companies presents businesses with a unique opportunity to eliminate production costs associated with human labor totally or in part.

Gain Access to An Expanding Customer Market

China is the most populous nation on earth, giving businesses direct access to one of the world’s biggest and fastest-growing consumer marketplaces.

Additionally, China’s strategic location provides additional market entrance advantages if companies want to launch items in other Asian and European countries.

Better Quality Control

For parts and finished goods to perform correctly, they must be accurately machined. You may not have trouble receiving first-rate results if you hire another business to complete this task. To help ensure that the products are precise and available for use, most Chinese CNC machining follow extensive quality control procedures in place.

How to Find a Reliable CNC Machine Shop in China?

Due to its cost-effectiveness and high-quality manufacturing, China has become a more attractive destination for firms looking to outsource their CNC machining needs. To ensure the best outcomes, it is essential to consider some criteria before deciding to outsource your CNC machining requirements to China.

Communication

When hiring Chinese companies to perform CNC machining, effective communication is essential. Join forces with a business that is adept at intercultural and linguistic communication. Make sure the business you choose has a committed group of project managers who can keep open lines of contact with you during the entire process, from design to manufacturing.

Examining Cost

Even while it is frequently less expensive to outsource CNC machining to China than to produce them domestically, examining all associated costs, such as those for quality assurance and communication, is crucial before committing resources.

Production Management

Quality is an important aspect of any manufacturing endeavor as it often determines market acceptability. This is why it is often best to look for companies like XinCheng that implement strict production management when outsourcing CNC machining to China.

Capacity and Experience

If you’re looking for a Chinese quick prototyping company, verify that it has the machines and production capacities necessary to complete your order, such as CNC milling and turning machines, multi-axis machining systems, and more.

Ensure the company has good working experience with the type of material you demand, whether metal, plastic, or another substance. Also, ensure they have the right professionals to produce your order successfully.

Intellectual Property Protection Guarantee

Protecting your intellectual property is crucial when you contact CNC machining service in China. Verify the company’s strong intellectual property protection methods before choosing it. This entails executing non-disclosure agreements (NDAs) and preventing the leaking of your ideas and specifications to outside parties.

Certifications

This is one of the most crucial factors in selecting a CNC machining company in China to produce your parts. Whether you are outsourcing for quick prototyping and production, examine their credentials to determine whether they fit to produce your parts.

Additionally, it is best to ensure the Chinese company you are outsourcing to is ISO 9001:2015 certified, as this ensures they meet industry standards.

Future of Outsourcing CNC Machining to China

As more businesses and product engineers understand the benefits of CNC machining, outsourcing CNC machining to China is a trend that will likely continue to gain traction in the coming years.

High Quality and Technological Advancements

China’s CNC machining services have invested in cutting-edge technology, machinery, and software, including CNC software, hardware, networks, and automation. This investment is timely as it guarantees these machining companies can help companies increase the quality and innovation of their products and services. Chinese businesses also adhere to international standards and certifications like ISO, CE, and RoHS to safeguard their quality and reputation.

Growing Market

China is the world’s largest consumer and producer of CNC machined parts, with a sizable production potential. Considering that the market for CNC machined products is growing rapidly, they can provide businesses with access to a sizable and expanding market and demand.

The need for CNC machining in China is fueled by the government’s support of investments in the sector and demand from various industries, including the automotive, aerospace, shipbuilding, and 3C industries. China has a convenient and effective logistics network and a strong partnership with foreign-funded businesses, which may assist businesses in increasing their worldwide reach and competitiveness.

Why Choose XinCheng Machining Services in China?

Xincheng provides various CNC machining services, including milling, turning, wire EDM, and more. At XinCheng, we combine our 3-axis, 4-axis, and 5-axis CNC machines with our experts and cutting-edge equipment to produce CNC machined parts using various materials, including metal and plastic.

We are a reliable and experienced CNC machining manufacturer and supplier in China, whether you require CNC machining services for simple or complex designs or small or huge quantities.

We also guarantee reduced costs, and better quality, and increase your worldwide competitiveness. To get a free quote and begin your CNC machining project with China, contact us today.

Read More: Cost of CNC Machining

Conclusion

We have discussed the different facets of Chinese CNC machining services, from their development and influence to their benefits, prospects, and future. Besides, we have offered some helpful advice and details on outsourcing CNC machining tasks to China and what to anticipate from the typical machining services Chinese businesses give.

FAQs

Are Chinese CNC machining services of high quality?

Yes, a lot of Chinese CNC machining businesses are ISO-certified, demonstrating that their procedures adhere to global norms. To produce products of a high caliber, they employ advanced machinery and qualified workers.

How does outsourcing CNC prototyping to China work?

Finding a trustworthy partner, talking about your project needs, and sending them design files are all necessary steps in outsourcing CNC prototyping to China. The Chinese manufacturer will then use its CNC machinery to create a prototype, and you’ll get the finished product to evaluate.

Are there any challenges when outsourcing CNC machining to China?

Competition, growing costs, and being current with technological improvements are potential difficulties when outsourcing CNC machining to China. You can overcome these obstacles by developing a strong relationship with your Chinese partner and keeping yourself informed.