Prototyping Manufacturing Services for Every Industry

XCMachining’s provides the best prototyping manufacturing services, trusted by Engineers, Designers, and Product Teams Worldwide. We deliver fast, reliable, and precise plastic and metal prototypes to clients across the United States and around the world.

- On-demand manufacturing with flexibility.

- Rapid prototyping for custom designs.

- Transforming concepts into real products.

- All uploads are secure and confidential

Our Prototype Manufacturing Capabilities

XC Machining provides a wide range of prototype manufacturing services to help you create prototypes and produce parts in any quantity, from small batches to large runs. With our advanced equipment and reliable partners, we deliver complex, high-quality parts quickly and accurately.

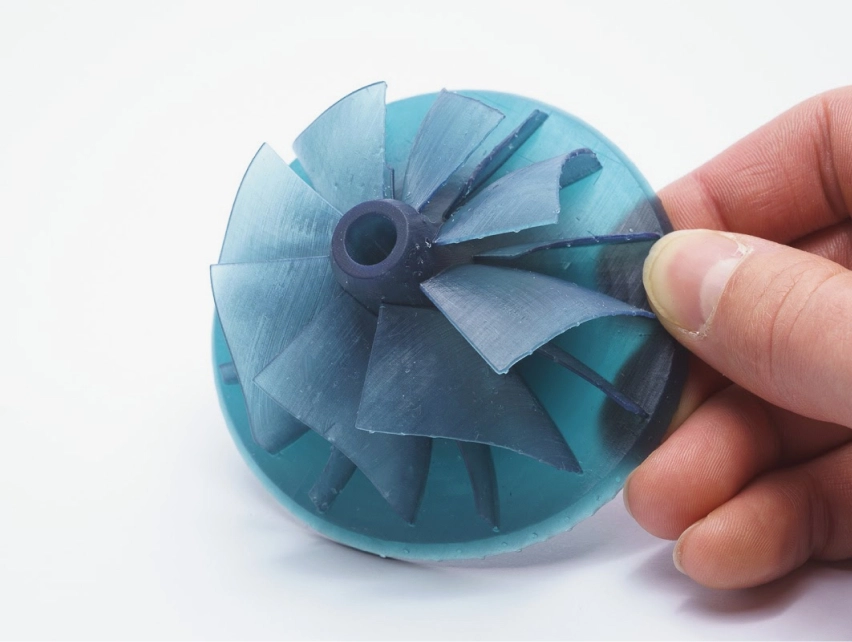

Get reliable vacuum casting services for high-quality prototypes and production parts at competitive prices. XinCheng offers highly detailed casting parts with consistent quality.

Sheet metal fabrication uses cutting, bending, and forming techniques to create precision metal components for industrial, commercial, and manufacturing applications.

Leverage our injection molding services for high-quality prototypes and custom parts, with expert support, competitive pricing, and faster production cycles for reliable, efficient results.

Custom and specialized die casting services for all types of metal parts as well as customized products. High-Precision die casting parts to meet your needs. Request to get a quote today!

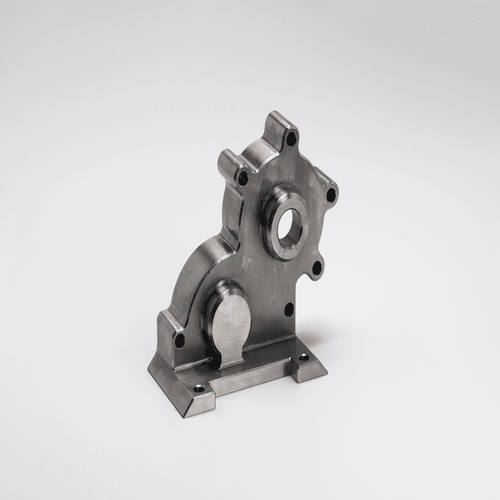

With 3, 4, and 5-axis CNC machining services, we can produce complex prototypes and parts with precise tolerances. More than 60+ materials are available for you to choose from.

Get high-quality custom 3D printing services for prototype and production parts. Whether SLS or SLA, we deliver efficient solutions to meet your design and production goals without limitations.

Your Trusted Prototype Manufacturers

For over 15 years in the prototype manufacturing industry, we’ve established ourselves as trusted prototype manufacturers, supporting product innovators in the USA, Europe, and global markets with high-quality prototypes and manufacturing solutions.

Whether you’re refining a medical CNC device, testing aerospace components, or launching a new consumer product, XCMachining offers the expertise and technology to ensure your parts meet exact specifications.

Why Choose Our Prototyping Manufacturing Services?

XC Machining develops rapid prototypes and parts through efficient manufacturing design and prototyping services, combining deep manufacturing expertise with advanced equipment. We are a reliable on-demand production company and ensure our products meet exacting tolerance specifications and quality standards.

Strong Manufacturing Capabilities

In our facility, you have a variety of machines for part production, including CNC turning lathes, milling machines, injection molding equipment, state-of-the-art 3D printing technology, and more.

Flexible Material Selection

At XC Machining, we try to ensure your choice is not limited, which is why we offer over 60 materials for you to choose from for your prototypes and products.

24/7 Engineering Support

In-depth service engineers with the knowledge to address your manufacturing inquiries are available from XC Machining. Our engineers are always on the ground to offer valuable advice.

Choice of Custom Finishes

We offer a range of surface treatments and custom finishes on solid metal and plastic parts, including anodizing, spray painting, vapor polishing, sandblasting, silk screening, etc.

From Prototype to Production—Scale with Confidence

We don’t stop at prototypes. Our integrated cnc prototyping and manufacturing services let you move seamlessly into low volume production. Whether you need a bridge solution before full-scale tooling or a short-run batch to meet demand, we have the capabilities to scale at your pace.

Our Production Services Include:

- All uploads are secure and confidential

in metal & plastic prototype and part manufacturing.

Customer Served

How to work with US?

Upload File

Submit your CAD files (STEP, IGES, STL, or PDF). Our engineering experts will review your design and provide recommendations if needed.

Get Quote 10 Hours

Choose the best materials and machining methods for your needs. Our team will support you in making optimal technical choicesc.

Approve and Production

Once we review your files and preferences, we’ll send a detailed, competitive quote typically within 24 hours.

Delivered

Approve the quote to move forward. Upon confirmation, we begin machining immediately to meet your delivery timeline with precision.

Industry Expertise at XC Machining

Having produced millions of parts, XC Machining holds deep knowledge in numerous applications. We excel particularly in industries requiring precise and intricate component fabrication. Trust us to deliver expertise and quality, no matter the complexity.

Discover the genuine experiences of our customers. Their words carry more weight than our claims. Explore how we’ve exceeded expectations and fulfilled unique requirements.

innovative-design-solutions

XC Machining has been an outstanding partner for our product development. Their team provided best design solutions that helped us improve our parts and reduce costs. The prototypes were delivered on time and exceeded our quality expectations

Edward Starc

Quality and Dependability

“Great quality, excellent service! XC Machining’s prototyping solutions streamlined our production timelines without sacrificing quality. I recommend them for precise, custom manufacturing.”

Mark D.

Speed and Precision

“XC Machining’s quick quotes and attention to detail were exceptional. Their expertise brought our design to life promptly. A dependable partner for innovative projects.”

Sophia L.

Impressive Material Options

“The materials and finishes available at XC Machining are top-notch. Their DFM analysis greatly improved our design, and the pricing was excellent. Highly recommended!”

Liam T.

Seamless, Quick Service

“Exceptional service! XC Machining delivered quality prototypes quickly, and their support team was highly responsive. I highly recommend them for reliable, custom manufacturing solutions.”

Emma R.

Exceeds Expectations Always

“XC Machining exceeded our expectations in both precision and speed. The team ensured our specifications were met, making them our trusted partner for rapid prototyping and manufacturing.”

John S.

Get in Touch

Bring Your Designs to Life with XC Machining

- Expertise Shared Widely

- Market Reach Expanded

- Advanced Technology Integrated

- Collaborative Innovation Opportunities

- All uploads are secure and confidential

Get In Touch

Prototyping Manufacturing FAQs

Do you ship internationally?

Yes, we work with clients around the world and offer fast, reliable international shipping to the USA, Europe, and beyond.

Can you help improve my design for manufacturing?

Absolutely. Our team offers design-for-manufacturing (DFM) feedback to help you optimize your parts for better performance, cost-efficiency, and faster production.

How fast can I get a prototype made?

Lead times depend on the complexity of your part and the chosen manufacturing method, but we typically deliver prototypes within 3–7 business days.

Do you support both low-volume and high-volume production?

Yes, we support everything from one-off prototypes to high-volume manufacturing. Our flexible production setup allows us to meet the needs of startups and large-scale enterprises alike.

What types of manufacturing services does XC Machining offer?

We offer a wide range of services including CNC machining, 3D printing, injection molding, sheet metal fabrication, and more. Whether you need a prototype or full-scale production, we can handle it.