Custom Injection Molding Services

Take advantage of our extensive range of injection molding services for high-quality plastic prototypes and custom parts. Get professional engineering support for custom injection molding of any size and complexity at competitive pricing and faster cycle time.

- No Minimum Order Quantity requirement

- 24/7 engineering support

- Instant quotes and fast lead times

Our Injection Molding Processes

From rapid prototyping to mass production, XinCheng offers an extensive range of injection molding capabilities for high-quality, precision-molded parts. Each injection molding process includes expert consultation on mold design, material, and surface finish selection. We ensure that every plastic molded part meets your unique specifications.

Rapid Injection Molding

Our plastic injection molding service employs precise molding tools to ensure a smooth manufacturing process. XinCheng delivers injection molded parts of varying sizes and complexities that meet your specific requirements.

Overmolding and Insert Molding

Get specialized overmolding and insert molding capabilities to create complex plastic parts. We combine high-quality substrates and plastic materials to give finished products with improved durability, functionality, and aesthetics.

Injection Molding

Get high-quality and accurate custom injection molds to create excellent plastic components. Our dedication to quality, prompt output, and reasonable pricing will help you improve your business results.

Why Choose XinCheng for Custom Injection Molding Services?

XinCheng is a professional custom injection molding service provider with extensive manufacturing capabilities and cutting-edge technologies. We combine our strong manufacturing facilities with experienced engineering teams to make superior and consistent quality components.

-

Expert Engineering SupportWe support your development goals through professional teams from design to shipping. XinCheng is committed to providing superior results while helping your save time and money.

-

Reliability and High QualityWith certified injection molding facilities, you can be sure of strict in-process inspection, dimensional verifications, and functional testing. XinCheng injection molding services include an extensive quality management system for molding consistent, high-quality plastic parts.

-

No Minimum Order Quantities (MOQs)We allow you to procure on-demand molded pars without MOQs. This ensures lower injection molding costs and speeds up the production of plastic molded parts from design to production.

-

Instant Quotations and Fast Lead TimesGet injection molding quotes within hours and molded parts within days! Our quotation system provides fast and accurate pricing to reduce the product development cycle and hasten parts production.

Custom Injection Molding Services: How it Works?

Custom injection molding in simple steps! See how our expert technicians and management system process your orders from quotation to production.

1. Upload Your Part Design

Upload your 3D CAD file to request injection molding quotes. Within 24 hours, our dedicated engineer will respond to get you ready to kickstart your project.

2. DFM Analysis Report

To ensure we create functional custom injection molds, we provide feasibility reviews of your design to meet requirements before beginning production.

3. Mold Flow Analysis

Make changes using predictive modeling software to examine how molten material behaves and moves inside the mold, which is necessary for machinability.

4. Mold Tooling Production

Our experts handle the complexities of mold tooling production. We use the most suitable materials and finishes to develop custom injection molds.

5. Sample Verification

Once the injection molding prototypes are ready, we will send samples to you to review to ensure quality and precision before volume production.

6. Start Part Production

After prototyping and functional testing, we move on to low-volume production. Our advanced machining techniques help us produce parts effectively.

7. Strict Quality Assessment

A strict assessment of the function, appearance, and dimensions ensures that the parts are of high quality and satisfy the desired specifications.

8. Shipping Products

After careful assessment, we will send your injection molding parts as soon as possible while ensuring their safety.

Injection Molding from Prototyping to Production

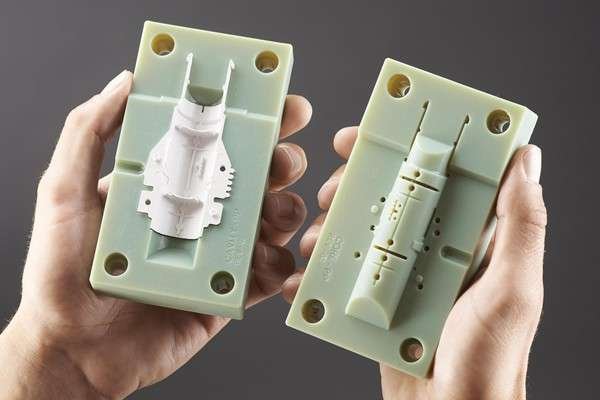

Prototype Injection Molding

Use high-quality prototype tooling to get quick design feedback and validation. Create high-quality injection molding prototypes for limited batches of plastic components. We are experts at producing prototype molds rapidly to guarantee you conduct functional tests and confirm market interest.

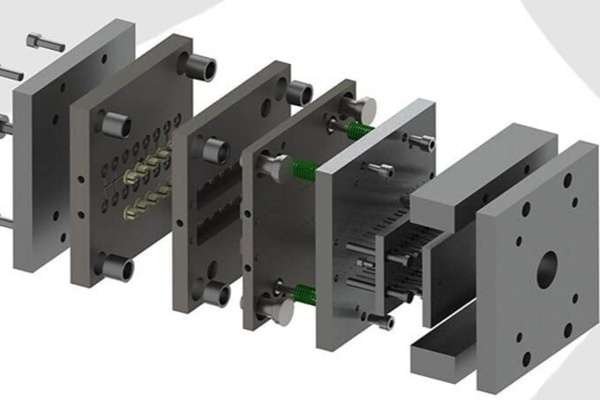

Production Tooling

XinCheng produces top-notch production molds for the manufacturing of plastic parts in large quantities. Our production tooling uses long-lasting aluminum or tool steel. We can also change the materials and production techniques depending on your particular needs.

Materials for Custom Injection Molding

Being at the forefront of plastic injection molding companies, XinCheng has an extensive selection of thermoplastics and thermosetting plastics to suit your requirements. We also help you select the best tooling materials for superior molding results.

Plastic Injection Molding Materials

The injection molding process is compatible with a wide range of plastic materials. XinCheng provides more than 60 plastic materials for your project, you can be sure of getting the most suitable plastic material for your project.

Acrylic (PMMA), acrylonitrile butadiene styrene (ABS), nylon (polyamide, PA), polycarbonate (PC), polyethylene (PE), polyoxymethylene (POM), polypropylene (PP), polystyrene (PS), thermoplastic elastomer (TPE), thermoplastic polyurethane (TPU).

Tooling Materials

We use high-quality tooling mold in low-volume or high-volume injection molding processes. Our material choices ensure the molds are durable enough to withstand long production runs. These are some of the common materials we use:

- Aluminum: 5052, 6061, 7075

- Stainless Steel: 301, 303, 304, 316, 316L, NAK80, 420

- Tool Ssteel: 718, 718H, 738, H13, NAK80, S7, P20, S136, S136H

Surface Finishes for Injection Molding

XinCheng offers a comprehensive list of secondary finishing operations to improve the mechanical and aesthetic appearance of your product. We will work with you to choose the suitable finishing option for your part’s application.

| Name | Description |

|---|---|

| Glossy (A) | This finish is made of diamond buffing and produces glossy and shiny surfaces on injection molded parts. |

| Semi-glossy (B) | This is a B-grade surface finish with a slightly rougher finish due to the use of grit sandpaper. Custom-molded plastic parts with this finish will have matte textures. |

| Matte (C) | A C-grade finish that produces rough and uneven surfaces with grit sanding stones. They also have matte surface textures. |

| Textured (D) | D-grade finishes use dry glass beads and grits to create a rough textured surface. Products can have a satin or dull finish depending on the material used. |

Advantages of Injection Molding

-

Efficiency and QualityAfter mold development, the injection molding process can operate at a remarkable speed, with fast cycle times. It is particularly beneficial for medium to high-volume production runs.

-

Large Material ChoiceInjection molding is compatible with a lot of materials, and they’re customizable. You can choose materials flexibly depending on the specific applications of your final part.

-

Excellent Surface FinishInjection mold tooling is carefully CNC milled and finished, giving the parts an excellent surface. Typically, the parts produced require little post-processing.

-

Scalability and RepeatabilityInjection molding is the cost-effective method for specialized manufacturing runs of 500 to more than 500,000 parts. It ensures the repeated production of identical products.

Injection Molding FAQs

Injection molding is a plastic production technique where plastic polymers are melted to create desired components. The molten plastic resins are solidified under pressure in mold tooling that has been pre-machined in the shape of the desired part. Custom injection molding can create thousands of parts with the same shapes and complexities.

We create injection mold tooling with production-grade steel or aluminum materials using CNC machining to ensure high accuracy and precision. Therefore, it is typically possible to achieve tolerances of up to +/- 0.005 inches for injection molded parts. Some machines can even achieve more restrictive tolerances.

You will get injection molding quotes after our platform has considered several variables, such as the component’s size, the complexity of the mold, the number of injection cavities, the materials, the requirements for post-processing, etc.

Injection molding is a highly versatile manufacturing process used in various industries. These include the aerospace, medical, electronics, and energy industries. Injection molding also helps produce consumer goods, including housewares, kitchen appliances, and cosmetic packaging. Toys and game manufacturers rely on injection molding to produce intricate, complex, customizable parts.

It takes approximately 35 days to design and create the mold and another three to five days to produce the molded parts after you make your order.

Yes, we offer production tooling for the on-demand manufacturing of custom plastic parts. This tooling option ensures multi-cavity capabilities, longer production runs, and a cost-effective molding process.

It takes approximately 35 days to design and create the mold and another three to five days to produce the molded parts after you make your order.