CNC Turning Services

Get high-performing CNC turned parts with professional turning experts. Efficient CNC turning services with competitive pricing and fast lead times from prototyping to production runs.

- Tight tolerances

- Prototypes and parts within days

- Instant quote and DFM feedback

What is CNC Turning?

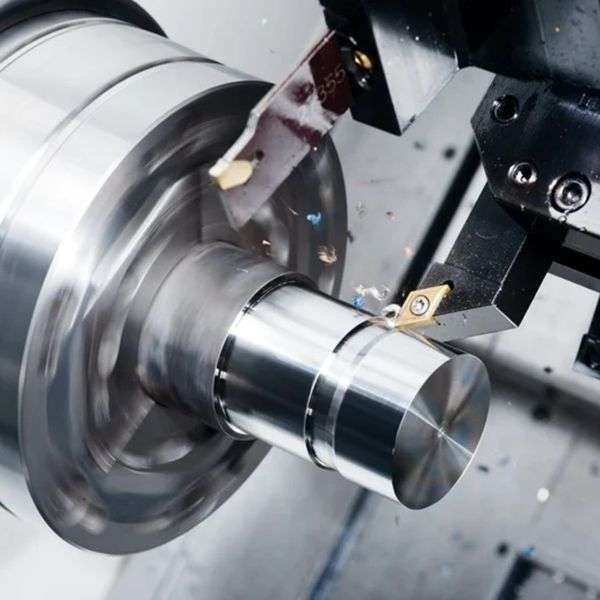

CNC turning is a subtractive method that involves the use of rotating chucks and stationary cutting tools to shape parts. It is particularly suitable for creating symmetrical parts along their center axis. In CNC turning, a blank bar of material is loaded into the chuck of the lathe’s spindle. The spindle holds the workpiece in place while it rotates. Once the spindle reaches its desired speed, a stationary cutting tool is brought into contact with the workpiece, gradually removing material until the desired shape is achieved.

After all machining operations are completed, the finished part is cut from the stock material for further processing. The CNC lathe can then repeat the operation with minimal setup time. The main objective of CNC turning is to machine parts with shapes that can be formed by cutting into a rotating bar of raw material.

Why Choose XinCheng for CNC Turning Services?

XinCheng is your reliable CNC turning company, delivering high-quality CNC turning services for various applications. We are committed to delivering superior prototypes and custom turning parts that meet your requirements.

-

High-Quality Turned PartsOur commitment to quality management systems ensures a consistent and exceptional standard for our products. Rigorous inspections guarantee the delivery of precision machined CNC turning parts.

-

24/7 Engineering SupportOur 24/7 engineering support is always available for you. XinCheng’s experienced engineers are ready to provide the most suitable solutions for part production, material selection, surface finishing options, and more.

-

Fast Lead TimeOur one-stop CNC turning capabilities help us improve the production of your prototypes or parts. With instant quotes and rapid production, you can significantly reduce cycle times by up to 50%!

-

Efficient Manufacturing CapabilitiesAt XinCheng, we integrate skilled technicians with cutting-edge technologies to achieve optimal manufacturing outcomes. Our team of experts also collaborates with you throughout the prototyping and production process.

CNC Turning Materials

Our CNC lathe services are compatible with an extensive range of materials. With 60+ engineering metals and plastics, we can create precise prototypes and CNC turning products.

Metals

Get a diverse selection of CNC turning metals that meet the needs of various uses and industries. Our metal machining materials include:

- Aluminum

- Brass

- Cast Iron

- Bronze

- Copper

- Steel

- Stainless Steel

- Titanium

- Zinc

- Magnesium

Plastics

Our extensive range of high-quality plastics is perfectly suited for producing rapid prototypes and precise turning plastic parts. Some of them include:

- Acrylic

- ABS

- Delrin

- PEEK

- HDPE

- Polycarbonate

- Polypropylene

- PA+GF

- ULTEM

CNC Turning Surface Finishes

At XinCheng, we offer an extensive range of surface finishes that can significantly enhance the quality of your products. Our surface finishing options for CNC turned parts are designed to improve the visual appeal and various functional aspects.

| Name | Description | Materials | Color | Texture |

|---|---|---|---|---|

| Anodizing | It increases wear resistance, hardness, and corrosion resistance while also preserving the metal's surface. | Aluminum | Gold, blue, clear, black, red, grey | Matte smooth finish |

| Bead Blasting | This finishing improves the visual appeal and is compatible with many other surface treatments. | Steel, Stainless steel, Aluminum, ABS | N/A | Matte |

| Brushing | Smoothens the part's surface, prevents rust formation, and can remove surface flaws from CNC turning parts | Aluminum, Stainless Steel, Steel, Brass, ABS | N/A | Satin |

| Electroplating | Electroplating enhances the durability and conductivity of products. It also improves their functionality and aesthetic appeal. | Stainless Steel, Steel, Aluminum | Black, Grey, Clear, Gold, Blue, Red | Glossy, smooth finish |

| Polishing | Polishing not only improves the component's appearance but also prevents contamination and reduces wear and tear. | Steel, Brass, Stainless Steel, Aluminum | N/A | Glossy |

| Powder Coating | It increases the durability and aesthetic quality of CNC turned parts. The corrosion resistance ability also further enhances longevity. | Steel, Stainless Steel, Aluminum | Black, Pantone number, or RAL code | Semi-glossy or glossy |

| Black Oxide | It enhances corrosion resistance and minimizes light reflection on the material surface. | Stainless Steel, Steel | Black | Smooth |

CNC Turning Tolerances & Standards

XinCheng is an ISO 9001-certified company dedicated to machining CNC turning parts to meet tolerance requirements. Depending on your design, our CNC metal lathe services can achieve different tight tolerances for you

| Metals, PEEK, and ULTEM | Other Plastics | |

|---|---|---|

| Linear Dimensions | +/- 0.01 mm +/- 0.0003 inch | +/- 0.05 mm +/- 0.002 inch |

| Hole Diameters(Not Reamed) | +/- 0.008 mm +/- 0.0003 inch | +/- 0.05 mm +/- 0.002 inch |

| Shaft Diameters | +/- 0.004 mm +/- 0.00016 inch | +/- 0.05 mm +/- 0.002 inch |

Applications Of CNC Turned Parts

XinCheng’s reliable and cost-effective CNC turned parts find extensive applications in industries such as automotive, aerospace, electronics, medical, and more. They are used in the production of complex and precise components, including shafts, bolts, nuts, connectors, fittings, and threaded parts. Our CNC turning services create intricate parts with tight tolerances, ensuring the consistency and reliability of these turned parts.

CNC Turning FAQs

In CNC turning, a computer program controls the CNC machine, which moves the cutting tool along the rotating workpiece. The program specifies the toolpath, cutting speed, and other parameters to create the desired part.

Yes, CNC turning can handle complex geometries by using specialized tooling and multi-axis machines. It can create features such as threads, grooves, and intricate contours with high precision.

CNC turning centers provide the flexibility to incorporate rotating cutters like end mills or drills. This feature allows the machine to handle asymmetrical features in parts, increasing machining freedom. CNC lathe machining also ensures ease of achieving radial symmetry, superior precision, and the ability to achieve a smooth surface finish.

When selecting a CNC turning service provider, consider factors such as their experience, equipment capabilities, quality control processes, lead times, and pricing. It's also important to review their portfolio and customer reviews to assess their reliability and quality of work.