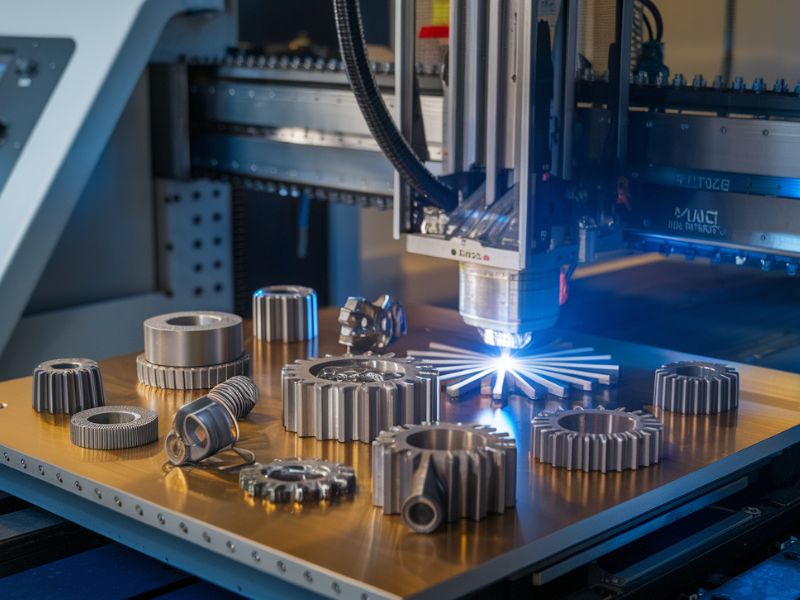

At XC Machining, we use state-of-the-art SLM machines to produce metal parts with exceptional precision. The SLM printing process involves several critical steps, each designed to ensure the highest quality results:

Design and CAD Preparation

The process begins with creating a 3D model of the part using CAD (Computer-Aided Design) software. The model is converted into an STL (stereolithography) file, which is compatible with 3D printing. The file is then sliced into thin layers that guide the SLM machine in building the part layer by layer.

Auswahl des Materials

SLM 3D printing can use a wide variety of metal powders, including stainless steel, titanium, aluminum, cobalt-chrome, and Inconel. The choice of material depends on the part’s requirements, such as mechanical strength, weight, heat resistance, and corrosion resistance. XC Machining offers a wide range of metal materials to meet the needs of various industries.

Laser Melting

The SLM machine spreads a thin layer of metal powder over the build platform. A high-powered laser then scans the surface of the powder, selectively melting it in the shape of the first layer of the part. The laser moves in a precise pattern dictated by the 3D model, and as the powder melts, it fuses together to form a solid layer.

Layer-by-Layer Construction

Once the first layer is complete, the build platform lowers slightly, and another layer of powder is spread over the previous one. The laser then melts the new layer, bonding it to the layer beneath it. This process continues until the part is fully built. The part’s geometry is constructed one thin layer at a time, allowing for the creation of highly complex features that are difficult or impossible to achieve with traditional manufacturing methods.

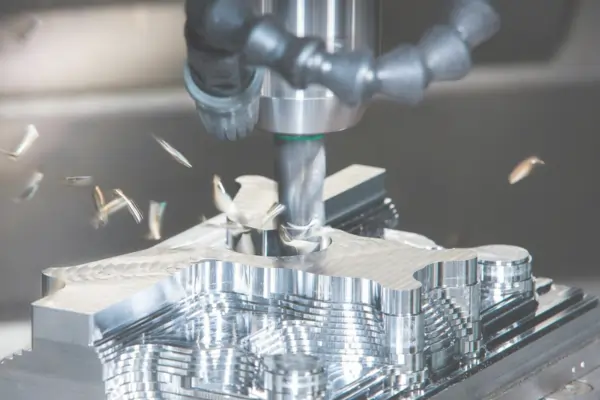

Nachbearbeitung

After the part is printed, it is allowed to cool. The next step is to remove the excess metal powder from the part, a process known as powder removal. Depending on the part’s requirements, additional post-processing steps may be required, such as heat treatment, surface finishing (e.g., polishing, sanding, or bead blasting), or machining to achieve the desired final properties and finish.

Perks of SLM 3D Printing at XC Machining

High Precision and Complex Geometries

SLM 3D printing is ideal for creating parts with intricate geometries and fine details that would be difficult or impossible to manufacture using traditional methods. This includes parts with internal channels, lightweight structures, and complex features that require high accuracy. SLM allows designers to produce parts that are lightweight yet strong, thanks to the ability to create lattice structures and optimized designs.

Fully Dense, High-Performance Parts

Unlike other additive manufacturing methods, SLM produces parts that are fully dense and possess mechanical properties comparable to those produced by traditional metalworking processes, such as casting or machining. This means the parts are strong, durable, and suitable for end-use applications where high strength and reliability are required.

Materialeffizienz

SLM is an additive process, which means it only uses the material necessary to build the part, reducing waste. The unused powder can be reused in subsequent print runs, making SLM a cost-effective and sustainable option for metal parts production.

Customization and Rapid Prototyping

One of the key benefits of SLM is its ability to quickly produce highly customized parts with complex geometries. Whether you need a one-of-a-kind prototype or a custom-designed part, SLM enables rapid iteration and design flexibility. You can create unique features without the need for expensive tooling or molds, making it perfect for rapid prototyping and small-batch production.

Shorter Lead Times for Low-Volume Production

SLM is particularly useful for low-volume and small-batch production runs, as it eliminates the need for costly and time-consuming mold creation. Whether you’re producing just a few custom parts or a limited production series, SLM provides a fast turnaround without the typical lead times associated with traditional manufacturing methods.

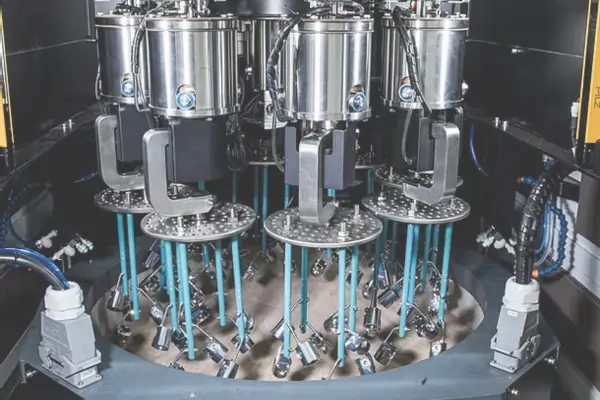

Choose XC Machining for SLM 3D Printing Services

XC Machining is the forefront of additive manufacturing and offers world-class SLM 3D printing services that cater to industries requiring high-performance metal parts. Our advanced SLM technology and skilled team of engineers ensure that every part we produce meets the highest standards of quality and precision.

Whether you need prototypes, custom parts, or low-volume production, XC Machining is the trusted partner for your SLM 3D printing needs. Our state-of-the-art SLM technology, combined with our expert team, ensures that we can meet your specific requirements and help you bring your ideas to life.

Contact us today to learn more about our SLM 3D printing services and how we can assist you with your next project. Whether you need rapid prototyping, custom parts, or low-volume production, XC Machining is here to help you achieve your manufacturing goals.