Einführung

CNC-Bearbeitungsdienstleistungen cut solid plastic and metal blocks into final parts with exceptional precision. Whether you need a single prototype or multiple parts for production, computer-controlled machine tools deliver the accuracy modern manufacturing demands.

The global CNC machine market reached $95.29 billion in 2024 and continues climbing toward $195.59 billion by 2032 Fortune Business Insights. Industries worldwide rely on precision CNC machining services because it produces parts on time with consistent quality.

XC Machining operates ISO 9001:2015 certified facilities with advanced CNC machine capabilities. Our online CNC machining service lets you upload your CAD file and get an instant quote within hours. From aerospace components to custom manufacturing projects, we deliver machined parts in as fast turnaround times the industry offers.

What Are CNC Machining Services?

CNC-Bearbeitungsdienstleistungen use computer numerical control to manufacture custom parts from metal and plastic materials. The CNC machine follows programmed instructions—cutting, drilling, and milling with precision impossible through manual methods.

The machining process starts with your design. Upload your CAD file to an online CNC machining service, and the system converts it into machine-readable code. The CNC machining services then removes material from solid blocks, creating custom CNC parts matching exact specifications.

Machining services handle diverse projects: prototypes for design validation, end-use parts for production, and custom threads for specialized assemblies. Whether you need machine parts with cylindrical features or complex geometries requiring 5-axis capabilities, modern CNC equipment handles the challenge.

Understanding CNC Machining Service Cost

Smart manufacturers understand what drives cnc machining costs before requesting quotes. Material selection hits budgets hardest—aluminum machines quickly and costs less, while titanium demands specialized tooling and slow feeds.

Machine Time and Tolerance Requirements

Precision machining takes longer than standard work. A simple bracket might machine in 30 minutes on a 3-axis mill. Complex parts requiring tight tolerance specifications can run hours. Advanced CNC machine controllers captured 41% of the component market in 2024 by optimizing tool paths and reducing cycle times Mordor Intelligence.

Standard tolerance of ±0.005″ comes included in base pricing. Tightening to ±0.001″ adds 30-60% premium. Specify tight tolerances only where parts mate—reducing the cost of CNC machining services parts significantly.

Quantity Economics and Instant CNC Quote

Setup costs stay constant whether producing one part or one hundred. Get an instant CNC machining services quote online to see how quantity affects pricing:

- Single prototype: $200-$800

- 10 custom parts: $60-$300 each

- 100 production parts: $25-$150 each

Online quote systems at quality shops calculate costs instantly when you upload designs. This transparency helps plan budgets accurately.

Optionen für die Oberflächenausführung

As-machined surfaces work perfectly for internal components. The cnc machining surface shows tool marks—acceptable for structural parts. Secondary finishes add cost: bead blasting ($10-$40), anodizing ($15-$80), or powder coating ($20-$120) per part.

Key Advantages of Precision CNC Machining

Precision CNC Machining Services operations deliver benefits traditional machining cannot match. Computer control eliminates human error, producing identical parts whether making the first piece or the thousandth.

Unmatched Accuracy for Machine Parts

Medical devices, aerospace components, and automotive assemblies demand exact specifications. CNC lathe machines held 30% market share in 2024 because of precision capabilities in shaping metal parts Market.us. That accuracy means parts fit correctly on first assembly—reducing rework costs.

Custom CNC machining handles complex geometries impossible through manual methods. Multi-axis equipment creates features from metal rod stock, machines custom threads, and produces intricate contours in single setups.

Material Versatility for Custom Manufacturing

A quality network of CNC machining shops stocks diverse materials. Aluminum alloys for high strength and low weight. Stainless grades for corrosion resistance. Engineering plastics like PEEK for chemical resistance. Each material selected for specific mechanical properties without manufacturing limitations.

Speed for Prototypes and Production Parts

The CNC milling market reached $15.67 billion in 2024 with manufacturers reporting 15% efficiency improvements through automation Global Growth Insights. Standard projects deliver within 5-10 days. Rush services provide quick-turn parts in 48-72 hours.

CNC milling and turning centers run continuously—maximizing capacity through lights-out manufacturing. What required multiple shifts of operators now runs automatically overnight.

CNC Machining Process: From Design to Finished Parts

Understanding the Bearbeitungsverfahren helps optimize designs and communicate effectively with manufacturing services.

Upload CAD File and CAM Programming

Every project starts with your design file. Online CNC machining service platforms accept standard formats—STEP, IGES, or native CAD files. The system reviews geometry, identifies potential issues, and generates tool paths automatically.

Computer-Aided Manufacturing software determines optimal cutting strategies, selects appropriate mill capabilities to machine parts efficiently, and sequences operations for fastest cycle times.

Machine Setup and Manufacturing Process

Technicians secure raw material blocks, install cutting tools, and load verified programs. They set work coordinates and run simulations verifying everything executes correctly. This preparation ensures quality from the first part forward.

Precision Machining Operations

CNC milling is a subtractive manufacturing method removing material with rotating cutters. The machine follows programmed paths with precision measured in thousandths. CNC turning rotates workpieces while stationary tools create cylindrical features from metal rod stock.

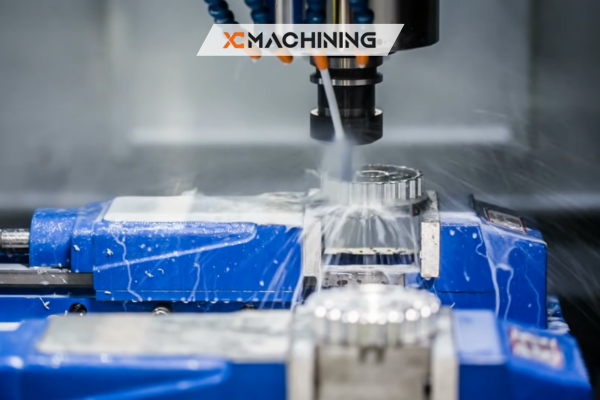

Modern equipment changes tools automatically—drilling holes, tapping threads, and creating complex features without operator intervention. Coolant manages heat while flushing away chips for clean cutting action.

Trusted precision CNC machining services offering exact cuts, smooth finishes, and consistent quality for complex components and professional manufacturing needs.

Quality Verification for CNC Machined Parts

Finished cnc-gefertigte Teile undergo dimensional verification using coordinate measuring machines and precision instruments. First Article Inspection Reports document every critical dimension—essential for aerospace and medical applications requiring full traceability.

CNC Machining Materials: Metal and Plastic Options

Material selection balances performance against cnc machining costs. Machining services work with extensive libraries covering metals, plastics, and composites.

Metals Used in CNC Machining

Aluminium-Legierungen offer excellent strength-to-weight ratios with easy machinability. Grade 6061 dominates prototyping and production work. Aircraft-grade 7075 provides higher strength for demanding applications.

Stainless steel cnc machining services delivers superior corrosion resistance for food processing, marine environments, and medical devices. Grades 304 and 316 machine slower than aluminum but provide durability justifying increased cnc machining service cost.

Brass and Copper excel where electrical conductivity matters. These metal alloys machine cleanly with attractive finishes.

Titan combines exceptional strength with biocompatibility—irreplaceable for aerospace and medical implants despite premium pricing.

Professional CNC precision machining services offering detailed craftsmanship, durable components, and precise results for industrial, mechanical, and custom design applications.

Engineering Plastics for Custom CNC Parts

ABS provides cost-effective prototyping with good impact strength and easy machining. Concept models often use ABS before transitioning to production materials.

Acetal (Delrin) offers low friction and dimensional stability—ideal for gears and precision mechanical components.

PEEK represents high-performance engineering plastic withstanding extreme temperatures and aggressive chemicals. Medical and aerospace applications justify higher costs through superior properties.

High-quality CNC plastic machining services delivering precise cuts, clean finishes, and custom plastic components for prototypes, industrial parts, and specialized manufacturing.

| Material | Bearbeitungsgeschwindigkeit | Stärke | Typische Anwendungen |

| Aluminium 6061 | Schnell | Gut | Prototypes, general parts |

| Stainless 316 | Mäßig | Ausgezeichnet | Medical, marine |

| Titan | Slow | Outstanding | Aerospace, implants |

| ABS-Kunststoff | Very Fast | Messe | Prototypes, housings |

| PEEK | Mäßig | Very Good | High-temp, chemical |

Custom CNC Machining for Different Industries

Manufacturing services support critical sectors where precision directly impacts safety and performance.

Aerospace and Medical Manufacturing

Aerospace demands components with complete documentation and tight specifications. Engine parts, structural brackets, and landing gear require materials traceability within thousandths of an inch.

Medical device custom cnc machining services produces surgical instruments, orthopedic implants, and diagnostic equipment. Biocompatible materials with pristine finishes meet FDA requirements through validated processes.

Automotive and Electronics Production

Automotive applications commanded 29% of the CNC machine market in 2024 Mordor Intelligence for engine components, transmission parts, and mounting brackets. CNC machined prototypes accelerate new vehicle development before production tooling investment.

Electronics rely on Präzisionsbearbeitung for heat sinks, component housings, and mounting hardware. Tight tolerances ensure proper thermal management in increasingly compact devices.

Getting Started with Online CNC Machining Service

Online cnc machining service platforms simplify ordering custom parts. Upload your design, select materials, specify quantities, and receive instant pricing.

Request a Quote Process

Quality shops provide detailed breakdowns showing material costs, machining time, and finishing operations. The system identifies design features affecting manufacturability—offering suggestions to reduce costs without compromising functionality.

Most platforms support standard file formats. Simply upload your CAD file, answer basic questions about tolerance and finish requirements, then get a quote within hours.

Design for Manufacturability Tips

Optimize designs to reduce cnc machining costs: specify realistic tolerances, use standard hole sizes, create generous corner radii, and minimize setups. These simple changes cut expenses 20-40% while maintaining functionality.

Custom manufacturing experts review complex projects—catching issues before machining begins. This design feedback prevents costly mistakes and accelerates delivery.

CNC Machining Capabilities and Equipment

XC Machining operates advanced equipment handling diverse machining projects. Our cnc shop includes 3-axis mills for straightforward parts, 4-axis equipment for rotational features, and 5-axis machines for complex geometries.

CNC Milling and Turning Centers

Cnc milling equipment creates flat surfaces, pockets, and intricate 3D contours. Cnc turning produces cylindrical components like shafts, bushings, and threaded fasteners. Cnc turning with live tooling combines both operations—machining complex features in single setups.

Unser mill capacity handles parts up to 40″ × 20″ × 20″. Turning centers accommodate diameters to 12″ and lengths to 24″. This variety of CNC machining services equipment produces everything from tiny medical components to substantial industrial assemblies.

Precision and Quality Standards

ISO 9001:2015 certification ensures consistent processes. AS9100 qualification serves aerospace customers. Our inspection equipment verifies dimensions to 0.0001″ accuracy—guaranteeing cnc parts meet specifications.

Schlussfolgerung

CNC-Bearbeitungsdienstleistungen transform digital designs into precision components efficiently and economically. Whether you need prototypes for testing or production parts for assembly, computer-controlled manufacturing delivers consistent quality.

XC Machining combines advanced equipment with experienced engineering support. Our online cnc machining service provides transparent pricing, fast turnaround, and reliable quality. Upload your design today and discover why manufacturers worldwide trust our precision cnc Fähigkeiten.

CNC Machining FAQs

What determines CNC machining service cost?

Material selection, part complexity, and tolerance specifications drive pricing. Setup costs, machining time, and finishing operations contribute to final quotes.

How quickly can I get machined parts?

Standard projects deliver within 5-10 business days. Rush services provide simple parts in 2-3 days for premium fees.

What tolerances can CNC machines achieve?

Standard operations achieve ±0.005″ routinely. Precision equipment reaches ±0.001″ or tighter using specialized processes and climate control.

Which materials work for CNC machining?

Metals include aluminum, stainless steel, titanium, brass, and copper. Plastics include ABS, Acetal, PEEK, and polycarbonate. Material selection depends on mechanical properties required.

How do I get an instant quote?

Upload your CAD file to our online platform, specify material and quantity, then receive detailed pricing within hours showing all cost components.

References

- Fortune Business Insights. (2024). “CNC Machine Market Size [2032].” https://www.fortunebusinessinsights.com/industry-reports/computer-numerical-controls-cnc-machine-tools-market-101707

- Market.us. (2024). “CNC Machines Market Size, Share | CAGR of 9.8%.” https://market.us/report/cnc-machines-market/

- Mordor Intelligence. (2025). “Computer Numerical Controls Market Size & Analysis 2030.” https://www.mordorintelligence.com/industry-reports/computer-numerical-controls-market