The electroless nickel plating process is a fully chemical-based deposition method where nickel ions are reduced to metallic nickel through a chemical reducing agent, usually sodium hypophosphite. Unlike electroplating, this process does not use electricity, resulting in a more uniform and controlled coating across complex geometries.

Step 1 – Surface Preparation

Before plating, components are thoroughly cleaned, degreased, and acid-etched to remove oil, dirt, and oxides. This ensures strong adhesion between the base metal and the nickel coating, forming the foundation for a high-quality plated layer.

Step 2 – Activation

The cleaned surface is dipped in an activating solution, often containing palladium chloride or similar catalysts. This step sensitizes the surface, enabling the chemical reaction that allows nickel ions to deposit evenly during plating.

Step 3 – Deposition

Once activated, the part is immersed in a heated electroless nickel bath maintained between 85–95°C. A chemical reduction reaction occurs, depositing a uniform nickel-phosphorus coating that builds evenly over the entire surface, including internal cavities and edges.

Step 4 – Rinsing and Drying

After plating, parts are rinsed in deionized water to remove chemical residues and then dried to prevent oxidation or spotting. Proper rinsing preserves the coating’s appearance and integrity.

Step 5 – Post Treatment

For applications requiring added durability, heat treatment may follow. This process increases hardness and wear resistance, allowing the coating to achieve values up to 1000 HV, depending on phosphorus content and heat treatment temperature.

What Are the Different Types of Electroless Nickel Plating?

Electroless nickel coatings are classified by phosphorus content, which directly affects hardness, corrosion resistance, and magnetic behavior. Each type is suited to different industrial needs, from tooling to marine applications.

Low-Phosphorus Coatings (1–4%)

These coatings deliver maximum hardness and wear resistance, making them ideal for molds, tools, and hydraulic parts exposed to friction. They maintain some magnetic properties and offer a bright metallic finish.

Medium-Phosphorus Coatings (5–9%)

Offering a balanced combination of hardness, ductility, and corrosion resistance, this is the most commonly used ENP type. It provides dependable performance in general engineering and automotive applications.

High-Phosphorus Coatings (10–13%)

Known for exceptional corrosion resistance and a non-magnetic nature, high-phosphorus ENP is used in marine, aerospace, and electronics industries. It performs exceptionally well in chemical and saltwater environments.

What Are the Perks of Electroless Nickel Plating?

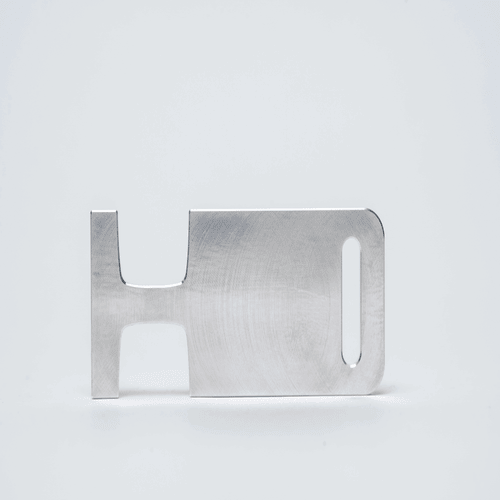

Electroless nickel plating delivers a powerful blend of mechanical strength, corrosion resistance, and visual appeal. Its ability to coat complex geometries uniformly makes it indispensable for precision-engineered components.

Uniform Coating

ENP forms a perfectly uniform layer over all surfaces, including holes, edges, and threads, something electroplating cannot achieve. This uniformity ensures consistent thickness and dimensional stability, critical for CNC-machined precision components.

Ausgezeichnete Korrosionsbeständigkeit

The high-phosphorus version of ENP offers superior resistance to rust, chemicals, and saltwater exposure. This makes it ideal for aerospace, marine, and oilfield components that operate under harsh or corrosive conditions.

Enhanced Hardness and Wear Resistance

After heat treatment, ENP coatings can reach up to 1000 Vickers (equivalent to HRC 68). This exceptional hardness greatly improves protection against abrasion, extending component lifespan in high-friction and high-load environments.

Improved Lubricity and Low Friction

Electroless nickel coatings naturally have a low coefficient of friction, which minimizes galling and sticking. This property enhances the performance of parts like pistons, valves, and molds that rely on smooth, sliding motion.

Non-Magnetic and Conductive Properties

Depending on the phosphorus concentration, ENP can be either non-magnetic or slightly conductive, making it highly versatile. It is particularly suitable for electronic, optical, and precision instrument applications where magnetic interference must be avoided.

Aesthetic Appearance

Beyond performance, ENP provides an attractive bright, satin, or mirror-like finish that enhances both the look and functionality of components. This makes it popular for visible parts in high-end industrial and consumer products alike.