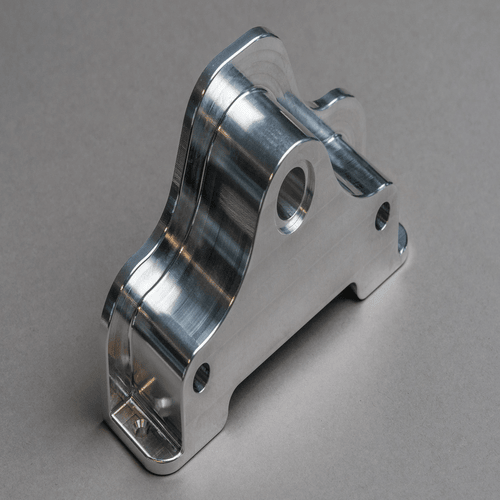

The advanced tools and innovations behind achieving flawless precision and low surface roughness.

High-Precision CNC Machines

XC Machining operates 3-, 4-, and 5-axis CNC systems built for stability and repeatability. Their rigid frames and vibration-damping structures ensure consistent tool engagement, minimizing chatter and improving surface uniformity.

Diamond-Coated and Carbide Tooling

Cutting tools play a defining role in surface smoothness. Our workshops use diamond-coated and ultra-fine-grain carbide inserts to achieve exceptional sharpness, reducing micro-scratches and burr formation during fine finishing.

Adaptive Control Systems

Modern CNC units feature adaptive control algorithms that automatically adjust feed and spindle speed in response to cutting conditions. This technology allows XC Machining to maintain constant load and smooth surface output under variable geometry or material hardness.

Non-Contact Surface Measurement Tools

We employ laser and optical profilometers for accurate surface roughness measurement. These instruments provide non-contact verification of Ra, Rz, and Rq values, ensuring every machined component meets or exceeds specification.

FAQs

What makes smooth machining different from standard machining?

Smooth machining focuses on achieving low surface roughness (Ra ≤ 1.6 µm) through controlled speeds, feeds, and optimized toolpaths. Unlike standard machining, it minimizes tool marks and micro-defects, delivering superior surface integrity straight from the machine.

How does material type affect surface smoothness?

Different materials respond uniquely to cutting. Aluminum and brass are generally machined to smoother finishes, while hard steels or titanium require specialized tooling and parameters. XC Machining customizes its process based on material hardness and thermal behavior to ensure optimal results.

Why is surface finish critical for functional parts?

Surface finish directly impacts friction, sealing, corrosion resistance, and wear. For precision assemblies such as medical implants or aerospace components, smoother finishes ensure reliability, improved performance, and extended service life.

Can smooth machining reduce the need for post-finishing?

Yes. When properly executed, smooth machining eliminates or greatly reduces secondary processes like polishing or grinding. XC Machining’s advanced CNC systems often achieve final-use finishes directly from the tool, saving both time and production cost.

How does XC Machining ensure consistency in surface finish?

XC Machining maintains strict process control using real-time monitoring, adaptive CNC systems, and non-contact surface measurement tools. Every batch is inspected for Ra and Rz conformity, guaranteeing uniform smoothness across all components.

Smart Coolant and Filtration Systems

Clean coolant means clean cuts. Our smart filtration systems continuously remove micro-particles, keeping fluids free of contaminants that could mar surfaces or damage tool edges—ensuring the finish remains consistently smooth.