Die wichtigsten Schritte bei der Herstellung von Kunststoff-Spritzgussformen

Before the mould design, the designer shall fully analyze and study whether the plastic injection mould products conform to the processing principle of injection molding. Careful negotiation with the product designer is required to reach a consensus. It includes the necessary discussion on the geometric shape, dimensional accuracy and appearance requirements of the product, so […]

Vakuumgießen vs. Spritzgießen: Die wichtigsten Unterschiede und die Wahl des richtigen Verfahrens

Choosing the right manufacturing process can be overwhelming even for experts. Though vacuum casting and injection molding are distinct processes, they have certain similarities, sometimes making choosing difficult. Using the wrong manufacturing technique may have a huge financial impact on your company. This makes it essential to have an in-depth knowledge manufacturing process before settling […]

Analyse der Merkmale des Auslassschlitzdesigns von Spritzgießwerkzeugen

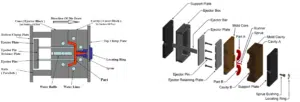

Introduction Injection Molding Injection molds is an efficient means of producing plastic products; it also ensures they have full structure and accurate dimensions. Used widely in mass production of complex shaped parts, injection molding involves injecting heated and molten plastic under high pressure into mold cavities before cooling and solidifying to form the final molded […]

6 Fehlerarten in der spanenden Bearbeitung: Ihre Ursachen und Optimierungsmaßnahmen

In machining, precision and efficiency are paramount. Whether in the manufacturing of intricate aerospace components or the production of everyday consumer goods, achieving the highest quality results while minimizing errors is a constant pursuit. This article explores mechanical machining, focusing on six common error types in machining that can occur, understanding what causes them, and finding […]

Zusammenfassung der Erfahrungen mit der Cnc-Bearbeitung, Was ist Cnc-Bearbeitung?

Introduction: CNC (Numerical Control Machining), also referred to as numerically controlled machining, refers to the practice of using numerically controlled tools to perform machining operations. CNC has several advantages over its traditional counterparts including stable quality machining with high machining accuracy and repeatability as well as the capability of handling complex surfaces efficiently and quickly. […]