precision, fine detail, and smooth surface finishes. This technology is perfect for applications where high accuracy and detailed features are paramount.

XC Machining offers top-tier SLA 3D printing services, providing our clients with the ability to produce intricate prototypes, end-use parts, and complex components with an unmatched level of detail.

What is SLA 3D Printing?

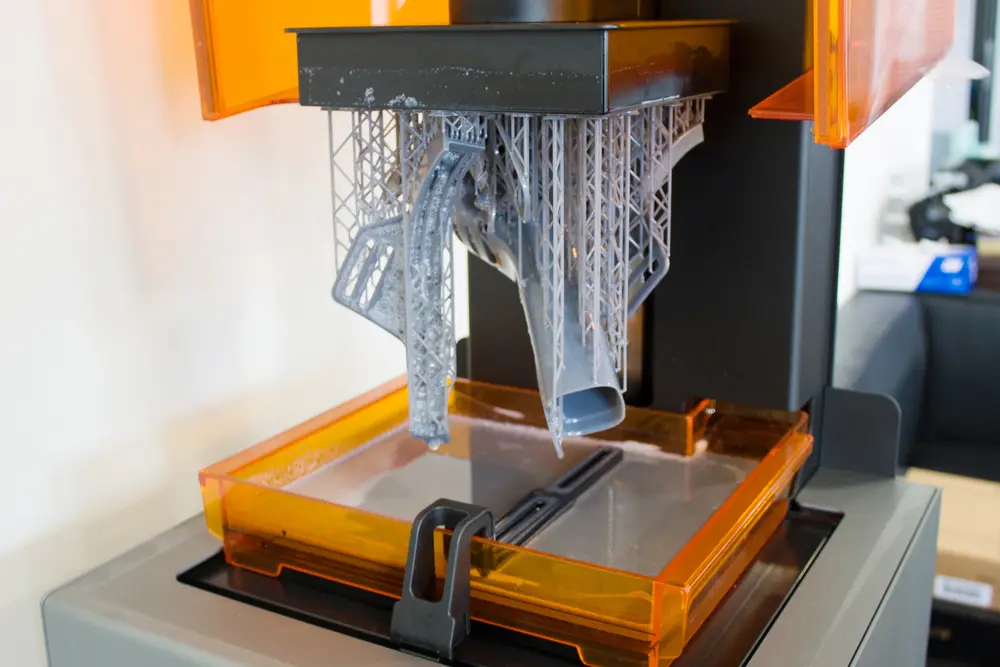

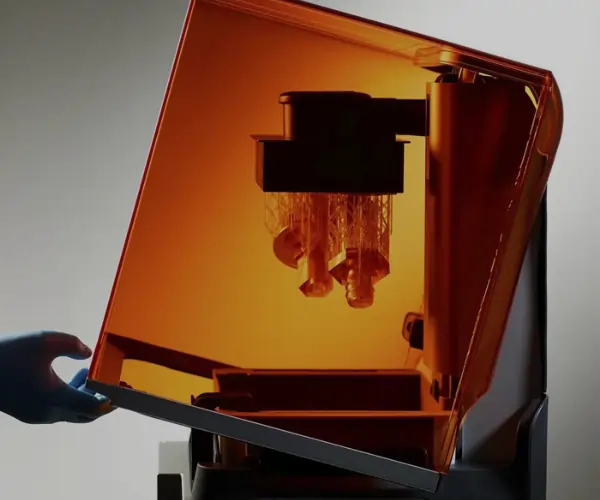

Stereolithography (SLA) is an additive manufacturing process that utilizes a laser to cure liquid resin layer by layer, building the desired object from the ground up. SLA is one of the oldest and most precise 3D printing technologies available today, providing high-resolution prints with fine details and smooth finishes that make it ideal for a wide variety of applications.

The SLA process uses photopolymer resin that is cured by ultraviolet (UV) light. The UV laser traces a path on the surface of the resin, hardening it in the shape of the first layer. After each layer is cured, the platform lowers, and the next layer of resin is added. This process continues until the part is fully formed.

Advantages of SLA 3D Printing at XC Machining

Exceptional Precision and Detail

SLA is renowned for its ability to produce highly detailed parts with excellent surface finish. It offers high resolution, often down to 25 microns, allowing for intricate geometries and fine features. This makes it the ideal choice for applications where precision and accuracy are critical.

Smooth Surface Finish

Parts printed using SLA have a much smoother surface finish than those produced by other 3D printing methods, such as FDM or SLS. The precision of the SLA process means that parts are often ready for use or further processing with minimal post-production work. This is especially important in industries like jewelry, dental, and consumer products, where surface finish is paramount.

Breite Palette von Materialien

SLA offers a variety of resin options, each with unique properties such as flexibility, high heat resistance, or transparency. This versatility in materials ensures that SLA can meet the needs of a wide range of industries and applications, from engineering prototypes to artistic models.

Highly Customizable

Our SLA service allows for the creation of highly customizable parts, whether you need unique features, specific shapes, or intricate designs. This makes it particularly useful for low-volume production runs, custom parts, or prototypes where every detail matters. The ability to iterate on designs quickly further enhances its value for product development.

Quick Turnaround Times

SLA printing provides quick turnaround times for both prototypes and final parts. Since the process requires no molds or tooling, parts can be printed and finished in a fraction of the time compared to traditional manufacturing methods. This is especially useful for industries that require rapid prototyping and need to make fast decisions based on design feedback.

SLA 3D Printing Process at XC Machining

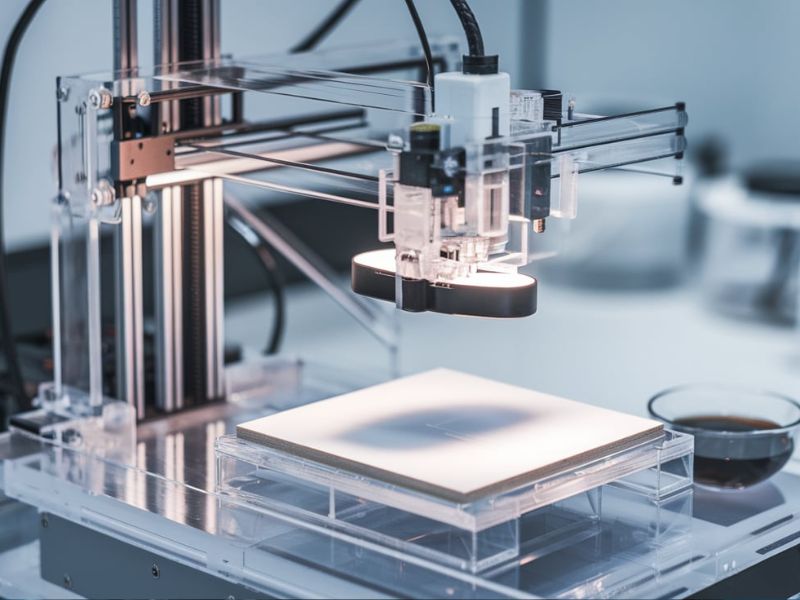

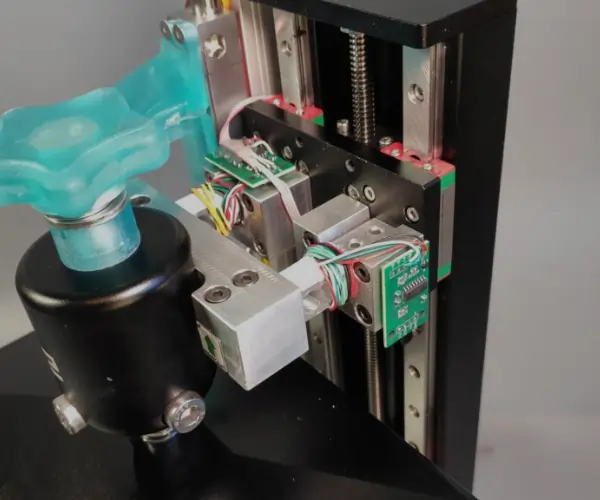

At XC Machining, we utilize advanced SLA 3D printers equipped with the latest laser technology to produce parts with exceptional accuracy and surface finish. The process involves several stages to ensure the highest quality results for our clients:

Design and File Preparation

The process begins with the creation of a 3D model, typically using CAD (Computer-Aided Design) software. The model is then converted into an STL (Stereolithography) file, which contains the data necessary for 3D printing. This file is sliced into thin layers that guide the laser during the printing process.

Auswahl des Materials

SLA printing uses photopolymer resin as the primary material, and there are various types of resins available to suit different applications. These materials can have properties ranging from high strength and rigidity to flexibility and durability.

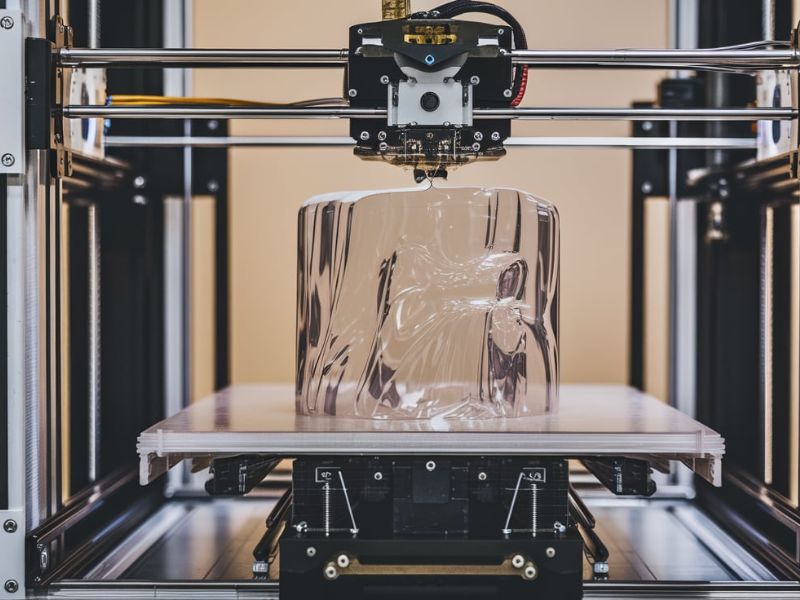

Printing the Part

The SLA printer uses an ultraviolet (UV) laser to selectively cure the resin in the shape of the first layer. As the laser moves across the resin, it solidifies the material in the desired pattern. The process repeats for each successive layer, building up the part layer by layer. This layer-by-layer approach is what enables SLA printing to achieve such high precision and fine details.

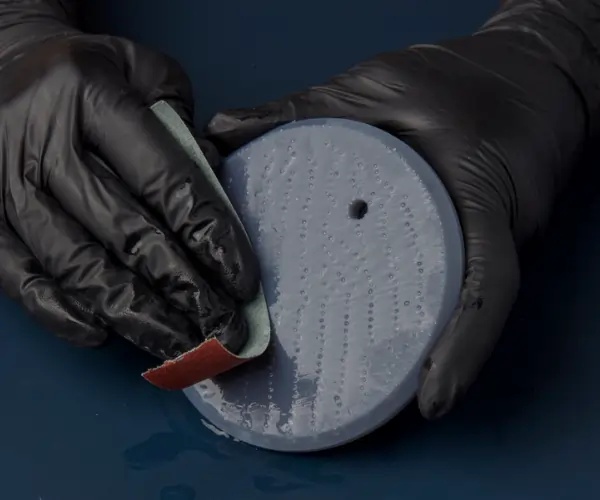

Nachbearbeitung

Once the part is printed, it must undergo post-processing to remove excess resin and ensure the final product is ready for use. This involves cleaning the part in a bath of isopropyl alcohol (IPA) to remove any uncured resin. Other post-processing steps can include sanding, painting, and polishing to achieve the desired surface finish.

Contact Us for SLA 3D Printing Services

If you’re looking for high-precision, fast, and reliable SLA 3D printing services, XC Machining is your go-to solution. Our advanced SLA technology and skilled team can bring your ideas to life with unmatched accuracy and surface finish. Whether you need prototypes, custom parts, or functional models, we’re here to help.

Kontaktieren Sie uns heute to discuss your SLA 3D printing needs, and let us help you create parts that exceed your expectations. Get in touch now to learn more about our SLA printing services and how we can help with your next project!