Metal bending is a combination of different technologies in association with enhancement of precise, rapid and consistent metal parts during its shaping process.

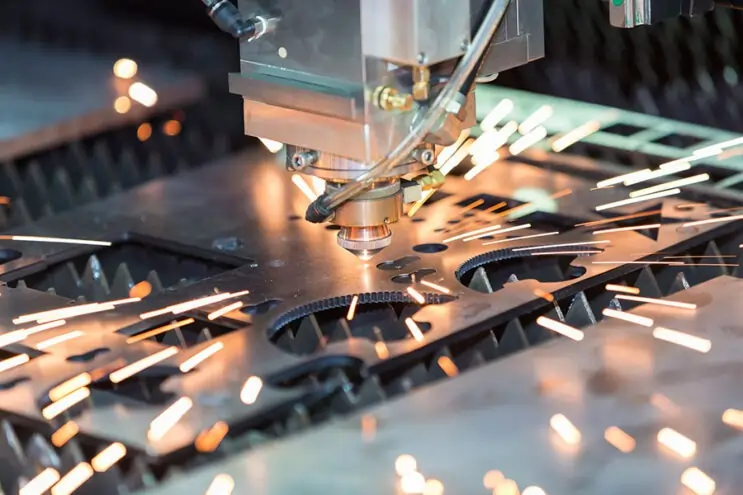

CNC Press Brake Technology

The modern basis of metal bending is CNC press brakes. Such machines work on computer-controlled settings so that they can precisely bend metal sheets according to the required shape. They provide repeatability of high levels, quick tooling time and high levels of accuracy in complex bends.

Hydraulic and Electric Bending Systems

Bending machines run through hydraulic as well as electric power. The hydraulic system has a greater force and hence is suited to thick materials, whereas the electric system is cleaner, faster, more energy efficient. Mostly they are combined with CNC controls to become more efficient.

3D Simulation and Bending Software

Before any metal is bent, 3D simulation software is frequently used to simulate- and test- the bending process by engineers. The tools assist in identifying the possible errors like springback or collision with a tool and optimization of the sequence of bending and minimization of the scrap and achieve greater precision.

Roll Bending Machines

They create bends and round shapes with the application of roll bending machines whereby sheet metals are crushed between two or more rollers. The technology is necessary to make pipes, cylinders, and others with rounded elements requiring a certain radius in long lengths or where there is the need to have a constant radius.

Robotic and Automated Bending Cells

Robotics involves automation in bending where the material is fed, positioned and unloaded by the robot system. High volume production is ideal with these advanced cells since it decreases manual labor and gives the same result in thousands of parts with very little mistake.

What Are the Best Practices and Tips for Accurate Metal Bending?

Achieving accurate metal bending requires a combination of careful planning, the right tooling, a solid understanding of material behavior, and the smart use of modern fabrication technology.

The Right Bend Radius

The right bend radius is an important parameter in this process. To ensure that bending is done safely, correctly and efficiently, consideration of the correct bend radius is vital since excessively large radius can end up compromising the integrity of part and fit as well as a radius that is too small that can lead to cracking of a brittle part, the internal radius must be at least the thickness of material being processed safely.

Tool selection and maintenance

Tooling is usually selected and maintained according to the following principles. By choosing the right tools and then caring for it, consistent outcome can be achieved in the bending process as die and punches have worn out and may contribute to poor angles, and defects in surfaces and it is therefore important to inspect, clean and select right tools in long-term accuracy.

Using Bend Allowance Deduction

Designing bend allowance and bend deduction in a correct manner avoids the chances of dimensional errors in the produced part thus making it vital to use sound formulas or CAD tools or bend charts based upon material type and thickness in order to develop successful flat patterns.

Importance of Grain Direction

The direction of grain of the metal sheet is also important considering that bending along with the grain would predispose the metal sheet to cracking, but bending opposite the grain would enhance ductility and lower the possibility of failure, especially on the hardened materials.

Leveraging CAD/CAM for Efficiency

The insertion of CAD/CAM technology to the bending process increases the efficiency and accuracy of the process as engineers are able to simulate the bending sequence, automate the calculations and set up required instructions to the CNC machine requiring less setup time and reducing the errors in production.