Laser manufacturing refers to the process of processing materials through interaction between lasers and materials according to certain requirements. Over the last 20 years, this technology has quickly spread into high-tech fields and industries and begun replacing or transforming some traditional processing industries, particularly automotive in developed nations where 50-70%-70% of parts are processed using lasers; laser manufacturing technology plays a pivotal role in improving research & development efforts and manufacturing levels within this sector.

Characteristics of Optical Manufacturing Technology

Laser is currently the main light source used in optical manufacturing technology. Laser beams possess many desirable characteristics such as high energy density, single mode frequency and directionality; giving optical manufacturing technology advantages over more traditional techniques. O/Off Pulse Interval) Control, making them ideal for automated processing and high production efficiency in large-scale manufacturing; their materials, shapes, sizes and processing environments offer great freedom; noise pollution during production is minimal due to no harmful rays or residues being released, with less mold waste and lower manufacturing costs as a result.

Types of Light Manufacturing Technology Used in Automotive Production

Light manufacturing technology for the automotive industry can be divided into three distinct categories: light “cold” processing, hot processing and rapid prototyping.

1. Cold Processing Technology

Optoelectronic manufacturing technologies that correspond with conventional cold processing techniques include laser cutting, drilling, marking and cutting.

Laser cutting offers fast, precise cuts with smooth surfaces and no burrs; no subsequent processing steps necessary; narrow cuts without mechanical stress or shear burrs on them; high processing accuracy and repeatability without damaging workpiece surfaces.

Laser drilling is fast and efficient, ideal for high-volume group hole processing; laser drilling achieves an ideal depth-to-diameter ratio and can process many materials such as hard, brittle and soft materials as well as small holes on inclined surfaces; it is also completely clean and pollution free during its production process.

Laser marking is an efficient and long-lasting non-contact marking solution, offering fast speeds and durable marking. Laser machines can easily integrate into assembly lines.

Laser cutting is a cutting method similar to milling that employs laser beams for layer-by-layer material cutting.

2. Optothermal Processing Technology

Optoelectronic manufacturing technologies that correspond to conventional thermal processing techniques include laser welding, surface strengthening, laser cladding and alloying.

Laser welding is the process of using an intense laser beam to locally heat metal being welded above its melting temperature, creating a joint. These welders can weld high melting point metals, non-metals, composite materials and other special materials efficiently; as well as dissimilar materials or special structures. Their welds have an efficient “self-purification” effect and high weld quality. Laser welding offers precise joins without filler metal, thanks to its light guide system and multiple devices forming a flexible processing system with high automation and production efficiency. Laser welding stands out among high-energy beam welding methods as its hallmark characteristic is not needing vacuum chambers and producing no x-rays during production.

Laser surface strengthening techniques are classified into two categories: laser transformation hardening and laser melting hardening. Laser transformation hardening (or laser quenching), more commonly known as rapid laser quenching, involves rapidly scanning a workpiece with an energy laser beam to raise its temperature above its phase transition point at high speed. After leaving an irradiated area, due to thermal conduction, the cold substrate rapidly cools down and undergoes self-cooling quenching for self-hardening quenching; the result being finer hardened layer structures and higher hardness than with conventional quenching methods. Laser melting hardening works similarly; except that heat from a laser heater heats the material surface to an elevated temperature creating fine-grained flame hardened layers on final parts’ surfaces.

Laser cladding is a process in which high-energy laser beams are used to irradiate materials that will quickly melt and bond to their substrate surface, producing an alloy coating with unique composition and properties that metallurgically adheres to it.

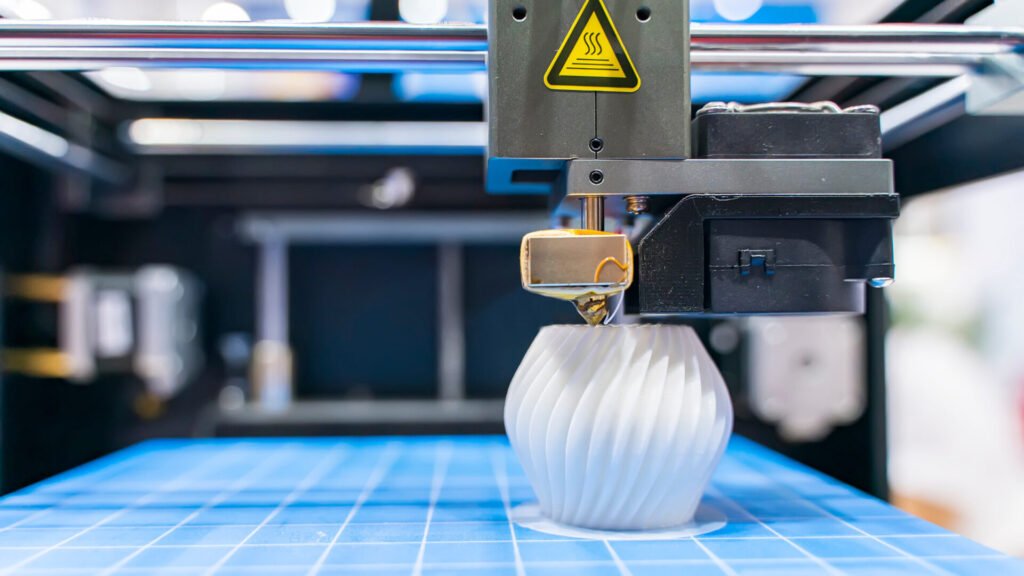

3. Rapid prototyping technologies using light materials

Rapid prototyping technology works on the principle that laser beams solidify molding material layer by layer under computer control, using data about your design model or part to guide this process – for instance CAD data. Construction of three-dimensional models using points and lines as building material; then stacking this surface precisely to form three-dimensional solid models or parts. Rapid prototyping technology is an efficient and effective technical approach to concurrent engineering and agile manufacturing that can dramatically shorten product development cycles, reduce costs associated with product creation, produce adaptable products that adapt rapidly to market changes, as well as quickly produce products with increased competitiveness in the marketplace. Rapid prototyping provides significant cost-savings over traditional product design methods and has also proven beneficial when utilized concurrently with agile manufacturing strategies.

Entering the new century, automotive production is entering an era of lean production that can effectively meet user needs. Automotive production has developed into an adaptable modular production method and high-tech automotive technologies are being implemented today. Automotive technology is currently experiencing an evolution from traditional mechanical to advanced manufacturing technology, with light manufacturing providing vitality to development and production of automobiles. Light manufacturing technology will likely become a mainstay of modern automobile production processes in this century; becoming an indispensable processing method.