Introduction:

Machining with 3-axis, 4-axis and 5-axis CNC systems has long been a staple in our industry and often appears dauntingly complex to users. Pictures may provide some clarity but often users simply do not share all the pertinent details with one another.

Understanding the big picture when working with CNC machining remains crucial, which aids our work immensely.

CNC milling machines can generally be classified by their operating axes, since their movements dictate which parts can be produced and thus determine production efficiency and accuracy.

More degrees of freedom typically allow for more complex geometry.

What are the differences among three, four and five axes machining centers? Their individual advantages will also be explored today as we discuss which products would make for excellent solutions in each scenario. XCmachining will review three distinct models; three axis centers (three), four axis centers (4ax) and five-axis centres (fiveax).

Three-axis CNC Machining:

Three-axis machining typically refers to three separate variable speed linear motion axes – left/right, up/down, front/back – that move at variable speeds simultaneously in various directions. Three axis CNC can only machine one surface at once; thus making it ideal for disc-type components that need multiple surfaces at the same time.

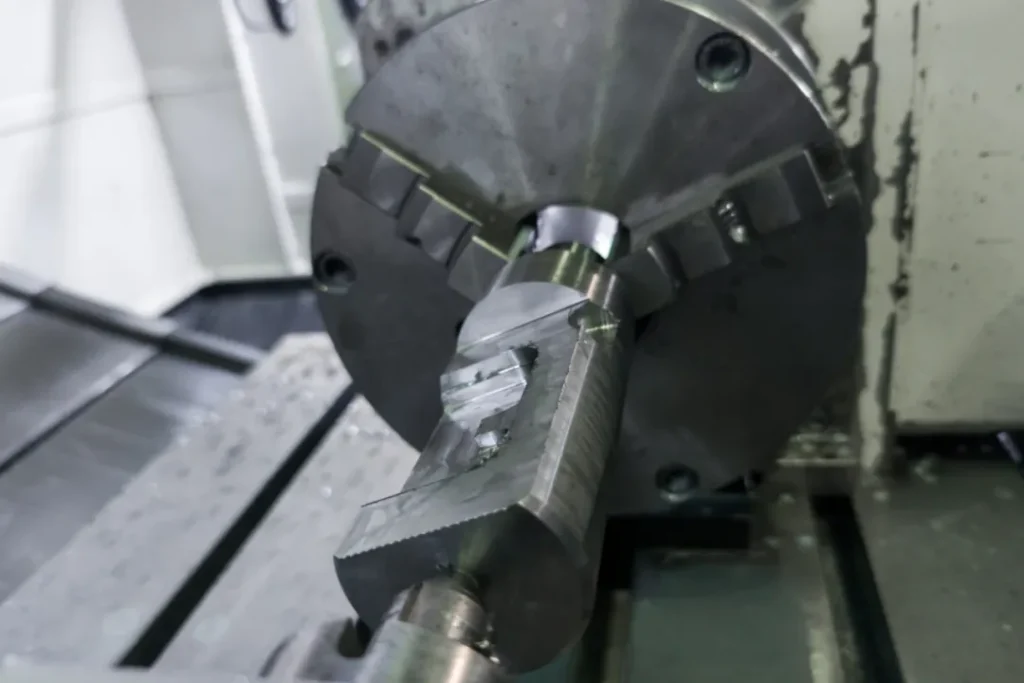

Four-Axis CNC Machining:

Four-axis CNC machining adds a rotary axis to the three existing axes, typically rotating the reference plane 360 degrees. However, this cannot operate at high speed and it is more suitable for box-type components.

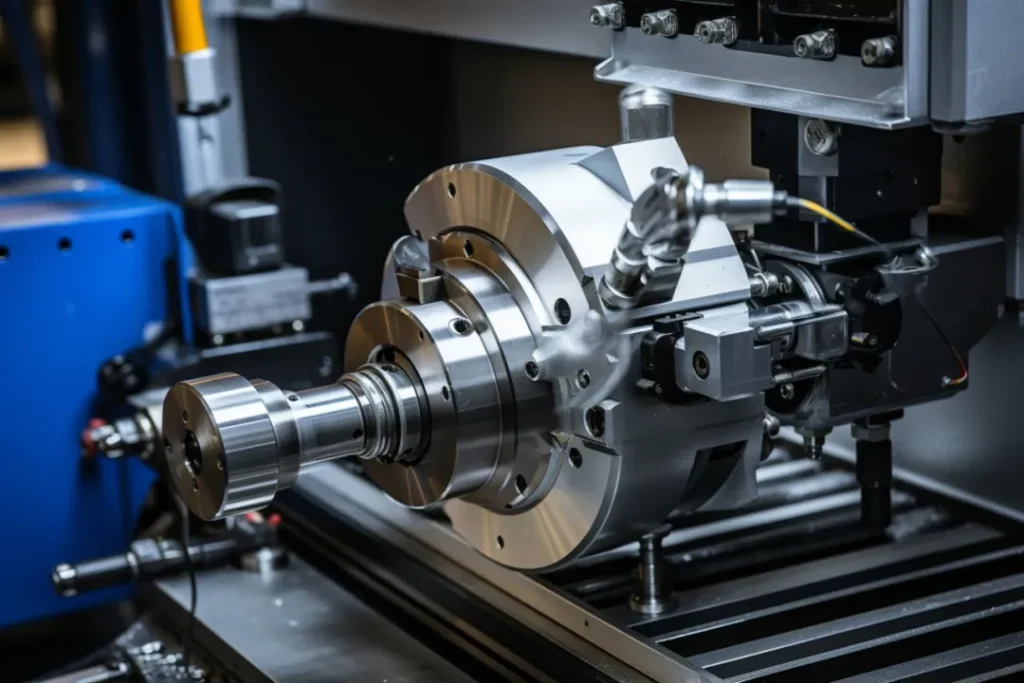

Five-Axis Machining Center CNC Machining:

When adding one more rotary axis (usually 360deg of rotation in the vertical plane) to four, comprehensive processing can be achieved, including one-time clamping to reduce clamping costs and scratch damage caused to product surfaces. It is especially suited for multi-station holes and flat surfaces with strict accuracy requirements as well as parts with high machining accuracy requirements such as parts with specific shape machining accuracy requirements.

5-axis machining centers may offer distinct advantages over 4-axis and 3-axis machines, yet not all products can make use of this machining method. Products designed for three-axis machining may not work when processed with five-axis machines; not only would the production cost skyrocket; their results may not even be satisfactory.