Are you confused about the price of Prototype Machining?

When customers first make prototyping models, they often ask why it costs more than 100$ dollars to make a prototype of an electric fan when they can buy one for 20 or 30 dollars.

This is also the difference between “batch” and “single or small quantity” production, as we often say.

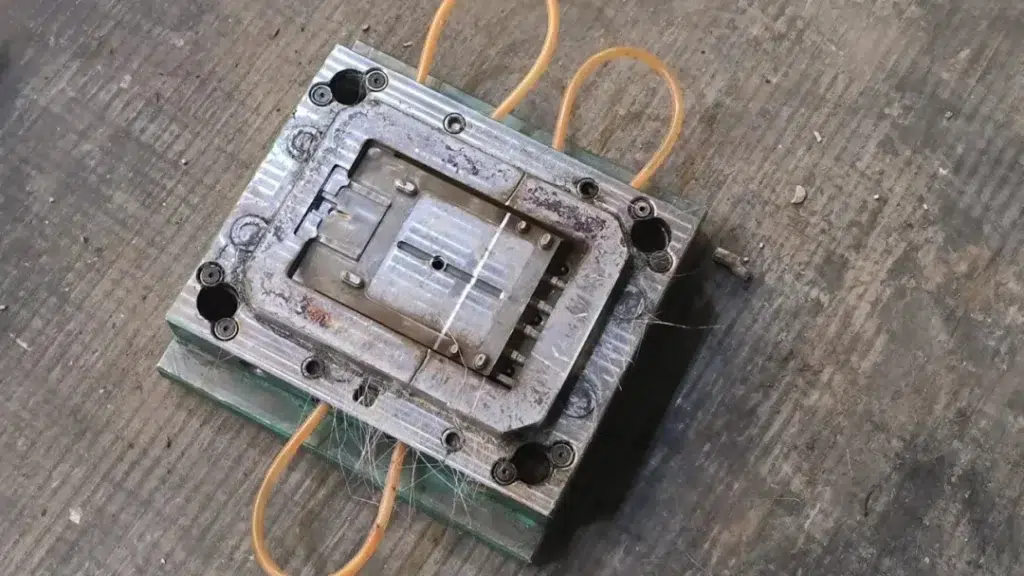

Take the mass production of hair dryers as an example. The current price of a set of ordinary hair dryer molds is about 100,00 dollars. If this hair dryer sells 100,000 sets, the price per product is also 1-2 dollars.

Of course, production includes costs such as electricity, assembly labor and site costs which should not exceed $5; materials cost under $10 while accessories come to less than $15 – giving a total production cost under $30 that depends on production quantity. Prototyping is an invaluable way for companies to move from research and development into mass production – it allows companies to avoid huge risks without incurring high expenses!

If this product is only made 10 sets, then its overall cost per unit is calculated as follows: the cost of the mold shared equally among each product is 10,000-15,000 dollars.

Electricity, assembly labor, and space cost 100-200 dollars per set. Material costs are 100-200 dollars per set, and accessories are generally around 50 dollars. The total cost per unit is 20,000 dollars.

Some people say that this is nonsense, who would only make 10 sets of molds. But I want to ask, who can guarantee that the design and molds you make can sell for more than 100,000… There is also the time cost, a mold takes about 2 months to make, and repairing it takes about half a month. If there are problems with the design, the mold will have to be scrapped, which will have to be calculated separately.

I want to say that it’s not the expensive prototype, but the different processes of the two. The cost composition is different, and there is no comparability. Enterprises choose the best way to realize products based on different stages of the product, considering risks and costs comprehensively.

Take another production method of hair dryer as an example:

3D printing programming, CNC programming, processing, post-processing grinding, oil injection, silk screen printing, etc. are all required to be processed manually. Especially for the grinding process, careful grinding is required to achieve good results. Furthermore, the wages of these grinding masters are also very high, generally reaching 30-50 dollars per hour, depending on the level of the teacher.

One hair dryer costs approximately $200-500, 10 prototypes about the same, and 100 units about the same price point. Do you realize that prototype technology used to produce one product does not differ much from producing 1000 units?

Mold making products range in cost from one to one thousand.

Prototyping is not expensive. Prototyping is not intended for mass production for ordinary people. It is an important way for companies to go from research and development to mass production. Compared to the direct mold production method, it is very cheap. Without prototyping, companies may face huge risks!