When you’re working with CNC (Computer Numerical Control) machines, getting things just right can be tricky. The code, the tools, the settings — there’s a lot to manage. So, how do you ensure you’re programming your CNC machine for success every time? What tips can help avoid common mistakes and make sure the machine runs smoothly?

CNC programming is the backbone of CNC machining, transforming a design into a precise, physical object. Whether you’re a beginner or someone with some experience, these 12 tips will help you refine your CNC programming skills, enhance efficiency, and improve the quality of your work.

So, let’s jump right in! Here are the tips you need to know to master CNC programming.

CNC Programming; Start with a Clear Design

Before you start typing out any code with CNC programming, you need a clear design in mind. It’s like building a house—you can’t start without a solid blueprint. Whether you’re working with CAD (Computer-Aided Design) software or hand drawing, make sure you have a detailed plan. Without one, you’re setting yourself up for mistakes and confusion.

When you create your design, pay attention to every detail. Dimensions, tolerances, and materials should all be considered. If you skip over any part of the design, it can lead to costly errors during machining.

- Key considerations: Ensure your design is precise and clear.

- Double-check your work before starting the code.

Taking the time to prepare your design will save you a lot of frustration later.

Understand Your CNC Machine’s Capabilities

Before diving into CNC programming, take some time to familiarize yourself with the machine you’ll be working on. Not all CNC machines are the same, so understanding your machine’s specific limitations will help avoid errors.

For example, not all CNC prototype machining can handle the same speeds, feeds, or materials. By knowing these factors, you can write code that fits your machine’s capabilities. If you’re unsure, always refer to the machine’s manual or speak with someone more experienced.

- Check machine specs: Understand the max speed and feed rates.

- Limitations: Don’t exceed the machine’s capabilities, or it could crash.

Knowing your machine well will keep your projects running smoothly.

Use Simple, Clean Code

When it comes to CNC programming, simplicity is key. Simple code is less likely to have mistakes, and it’s easier to troubleshoot. Avoid making the code too complex unless absolutely necessary.

Break your program down into smaller, manageable sections, and avoid overcomplicating the code. It’s tempting to write long, complex scripts, but this often leads to errors and confusion. If possible, stick to standard G-code, which is the most common CNC language.

- Keep it clear: Write code that’s easy to understand.

- Organize: Break up long code into smaller sections.

Good programming practice is about clarity and simplicity.

Double-Check Tool Selection

When programming for a CNC machine, always make sure you’ve selected the correct tool for the job. It might sound obvious, but the wrong tool can ruin your work.

The size, material, and type of tool you use impact the quality of your final product. For example, if you’re cutting metal, make sure you’re using a tool that’s strong enough to handle the material. Also, remember that tool wear can affect the quality of cuts, so always use fresh or well-maintained tools.

- Choose wisely: Pick the right tool for each operation.

- Check tool wear: Don’t use dull or worn-out tools.

Selecting the correct tool is key to achieving the desired outcome.

Set Proper Feeds and Speeds

Feeds and speeds control how fast the tool moves and how fast the material is cut. Incorrect settings can lead to poor surface finishes, excessive tool wear, or even machine damage.

It’s essential to adjust feeds and speeds based on the material you’re working with and the tool being used. As a rule of thumb, harder materials require slower speeds, while softer materials work well with faster speeds. If you’re unsure, consult the tool manufacturer’s recommendations.

- Speed adjustments: Match the material and tool to appropriate speeds.

- Feed rate: Ensure proper feed rates to avoid wear and tear.

Correct feeds and speeds will optimize the lifespan of both your tools and your machine.

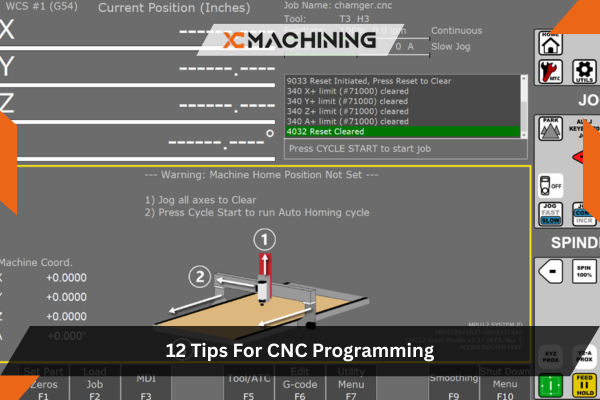

Simulate the Program First

Before running the program on the actual machine, always run a simulation. Many modern CNC programming come with simulation software that lets you preview the tool path. This step helps to ensure that there are no issues before the program touches any material.

Simulating the CNC machining magnesium can reveal hidden issues, such as incorrect tool paths, collisions, or unexpected behavior. It’s much cheaper to fix a problem in the simulation than to deal with the consequences on the shop floor.

- Simulate: Run a virtual version of the program first.

- Check for collisions: Ensure no parts will collide.

Simulation is an essential step to ensure smooth operation.

Keep Safety a Priority

CNC programming isn’t just about getting the code right; it’s also about safety. Always prioritize safety when programming and operating a CNC machine. For example, make sure the machine is properly set up before running the program. Lock any moving parts that aren’t part of the operation, and always wear safety gear.

Also, remember to follow the necessary protocols for setup and maintenance to avoid accidents.

- Safety gear: Wear gloves, goggles, and hearing protection.

- Check setup: Ensure all parts are secure and safe to operate.

CNC programming should always be done with safety as a top priority.

Understand G-Code

G-code is the most common programming language used in CNC machines. It’s made up of commands that tell the machine how to move when to cut, and what speed to use. As a CNC programmer, you’ll need to understand G and M codes to write effective programs.

Some of the most common G-code commands include:

- G0: Rapid positioning

- G1: Linear interpolation (cutting)

- G2/G3: Circular interpolation (clockwise/counterclockwise)

- Learn G-code: Familiarize yourself with basic G-code commands.

- Practice: Start with simple programs to build confidence.

Mastering G-code is an essential skill for any CNC programmer.

Plan for Tool Changes

Many CNC programming involve multiple tools, which means you’ll need to plan for tool changes during the program. Tool changes can introduce downtime and errors if they aren’t accounted for.

Make sure your program includes the necessary commands to properly swap out tools when needed. It’s also helpful to insert tool change positions in the program that minimizes the risk of collision or material waste.

- Tool change spots: Plan for the smooth transition between tools.

- Minimize downtime: Ensure the tool changes are efficient.

Planning tool changes carefully will ensure smoother, more efficient CNC operations.

Maintain Your CNC Machines

Just like you need to maintain your car, your CNC machines need regular maintenance too. Machines that aren’t properly maintained can lead to poor performance, inaccurate cuts, and even machine breakdowns.

Regular maintenance includes checking for wear and tear on machine parts, cleaning the machine after each use, and lubricating moving parts. It’s important to stay on top of maintenance to avoid costly repairs and ensure long-term machine reliability.

- Regular checks: Inspect parts and components.

- Clean and lubricate: Prevent dirt buildup and rust.

A well-maintained machine will perform better and last longer.

Optimize Tool Paths

Optimizing your tool paths is one of the best ways to improve the quality of your work and reduce machining time. Tool paths that are too complicated or inefficient waste time and lead to unnecessary tool wear.

Try to program tool paths that minimize the number of movements and optimize cutting conditions. This will save time, reduce wear on the tool, and improve the final surface finish of the workpiece.

- Minimize movement: Keep tool paths simple and efficient.

- Optimize cuts: Use strategies like climb milling for a better surface finish.

Optimizing tool paths will improve efficiency and quality.

Review and Refine Your Program

Once you’ve written your program, don’t rush into running it. Always take the time to review and refine your work. This means checking for any errors, unnecessary movements, or potential improvements. Refining your program can make a huge difference in machine time, tool wear, and the quality of the finished part.

It’s a good idea to have someone else review your program if possible. A fresh set of eyes can spot issues you might have missed.

- Check for errors: Go over every detail before running the program.

- Get feedback: Ask a colleague to review your work.

Taking the time to review and refine your CNC machining tolerance will save you time and money in the long run.

Understanding the Importance of Post-Processing

After writing the program, the next step is post-processing. Post-processing software converts the code into the specific format needed for the CNC machine you’re using. It makes sure that the G-code works with your machine, considering factors like machine type, tool offsets, and other specific configurations.

Without proper post-processing, even the best-written CNC programming could fail to execute properly, causing errors or machine damage. Ensuring your post-processing setup is correct is as important as the program itself.

- Custom post-processors: Use software that works well with your machine.

- Test the output: Always check the post-processed file before executing.

Good post-processing ensures your program runs smoothly on the machine.

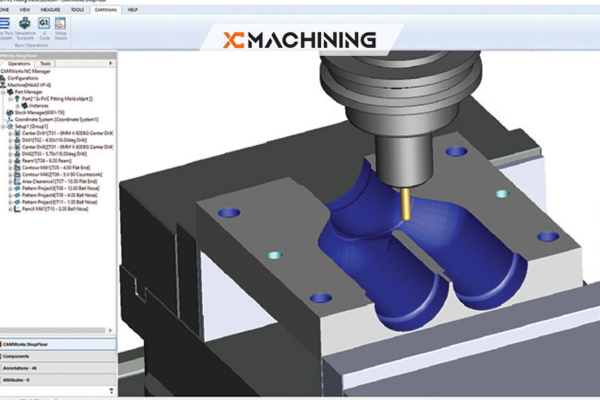

Mastering Multi-Axis Programming

If you’re working with a 3-axis machine, you’re already familiar with basic CNC programming. But, many modern machines have 4 or 5 axes, which allow for more complex and precise machining. Learning multi-axis programming opens up new possibilities for more intricate designs and faster production.

Incorporating the extra axes can be tricky, but understanding how they work and how to control them will significantly increase your programming skills. It requires learning more advanced code and a deeper understanding of the machine’s motion.

- Understand multi-axis setup: Learn how to use additional axes effectively.

- Take it step by step: Don’t rush into multi-axis without understanding the basics.

Mastering multi-axis programming can make a huge difference in your low-volume CNC machining capabilities.

Choosing the Right Cutting Strategies

Selecting the right cutting strategy is key to ensuring a smooth and efficient machining process. There are various strategies for different materials and parts, including climb milling, conventional milling, and adaptive milling. Each strategy has its advantages and disadvantages depending on the material, tool and desired finish.

Experimenting with different cutting strategies can help optimize your work and improve quality.

- Test cutting strategies: Try different approaches for better results.

- Adapt for materials: Choose the right strategy for the material you’re cutting.

So, finding the right cutting strategy can lead to smoother operations and better results.

Programming for Efficiency: Reducing Cycle Time

Reducing cycle time is one of the most important goals for CNC programmers. By optimizing the tool paths, adjusting feeds and speeds, and eliminating unnecessary movements, you can make sure that your machine runs as efficiently as possible.

One way to reduce cycle time is by maximizing tool efficiency, such as using larger tools when possible or implementing multiple cutting passes. These small changes add up to significant time savings.

- Optimize tool movements: Reduce unnecessary steps.

- Use larger tools: When appropriate, bigger tools work faster and more efficiently.

A quicker cycle time means more parts, faster delivery, and lower cost of CNC machining.

How to Troubleshoot Common CNC Programming Errors

Errors in CNC programming can be frustrating, but troubleshooting doesn’t have to be difficult. One of the first things to check is the code itself—look for missing commands or incorrect parameters.

Common errors include wrong tool offsets, incorrect feeds, and speeds, or poor toolpath planning. And having a systematic approach to troubleshooting will save you time and keep the machine running smoothly.

- Check for simple mistakes: Look for typos and incorrect values.

- Run a simulation: Simulate the program to catch mistakes before running it.

Effective troubleshooting saves time and prevents costly mistakes.

Conclusion

Lastly, CNC programming is an exciting and ever-evolving field. With these 18 tips, you’ll be well on your way to mastering your machine, optimizing your processes, and producing high-quality parts faster than ever before. Now that you have all these strategies, are you ready to put them into action and take your CNC programming skills to the next level?

FAQs

- What is CNC programming?

Answer: CNC programming involves writing code that tells a CNC machine how to move, when to cut, and what speed to use. It turns digital designs into physical objects.

- Why is it important to start with a clear design in CNC programming?

Answer: A clear design ensures your CNC program is accurate, preventing errors during machining. It acts as a blueprint, guiding every step of the programming process.

- What is G-code in CNC programming?

Answer: G-code is the standard language used to control CNC machines. It includes commands for movement, speed, and tool operations, helping machines perform precise tasks.

- How do feeds and speeds affect CNC programming?

Answer: Feeds and speeds control the tool’s movement and cutting rate. Setting them correctly ensures smooth cuts, prevents tool wear, and optimizes machining efficiency.