Introduction to 3D Printing Services

3D printing, also known as additive manufacturing, is revolutionizing the way products are designed, prototyped, and produced. This innovative technology builds objects layer by layer, using digital designs to create three-dimensional physical parts. 3D printing offers a range of benefits, from rapid prototyping to highly customizable products, making it a powerful tool for businesses in various industries.

XC Machining specializes in providing high-quality 3D printing services that turn your ideas into functional, precise, and durable prototypes or end-use parts. Our team is equipped with the latest 3D printing technology to offer customized solutions tailored to your specific needs, ensuring your project is executed with the utmost accuracy and efficiency.

How 3D Printing Works?

3D printing is a versatile process that uses a variety of materials and methods to create objects from digital models.

Here’s an overview of how the 3D printing process works:

Designing the Model: The first step in the 3D printing process is creating a digital 3D model. This is typically done using CAD (Computer-Aided Design) software, which allows for precise and detailed design creation. If you already have an existing design, it can be converted into a digital format suitable for 3D printing.

Material Selection: Depending on the desired properties of the final part, a variety of materials can be used in 3D printing. Common materials include thermoplastics, resins, metals, and even concrete. The selection of material depends on the part’s intended use, whether for prototyping, functional components, or end-use products.

3D Printing Process: The 3D printer reads the digital model and begins to build the part layer by layer. The material is deposited precisely, and each layer fuses with the previous one, gradually creating the full three-dimensional object. The printer follows the design’s specifications to ensure accuracy.

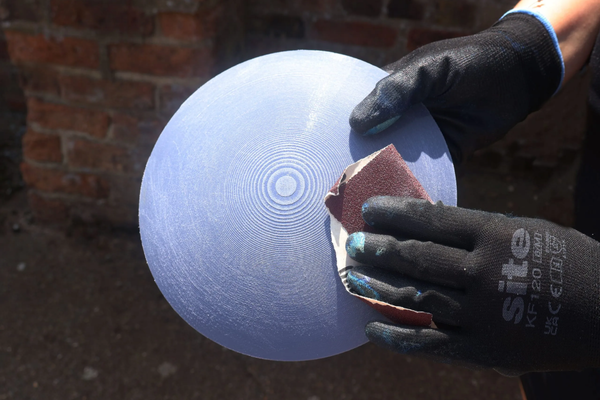

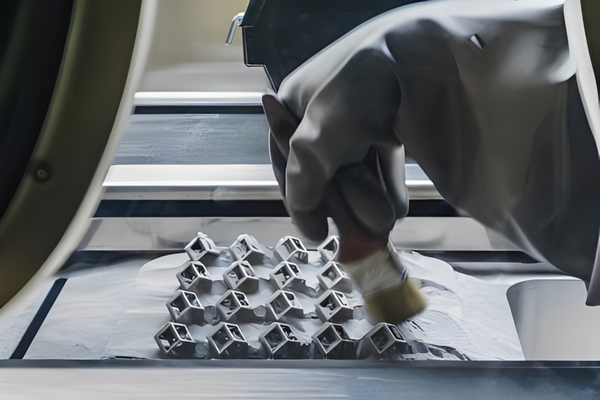

Post-Processing: After printing, the part may require additional post-processing steps such as cleaning, polishing, or curing (for resin prints) to improve its surface finish and enhance its functionality.

Final Inspection: Once the part has undergone any necessary post-processing, it is thoroughly inspected for quality. This ensures that it meets the required specifications and is free from defects.

Diverse Uses of Our 3D Printing Services

3D printing offers several advantages over traditional manufacturing methods, making it an increasingly popular choice for businesses and industries worldwide.

Some of the key uses include:

Rapid Prototyping: 3D printing allows for fast turnaround times in creating prototypes, enabling companies to test and iterate designs before moving to full-scale production. This can significantly reduce product development time and costs.

Customization: With 3D printing, it’s easy to customize designs to meet specific requirements. Whether you need small batches of customized parts or highly detailed features, 3D printing allows for greater flexibility than traditional methods.

Cost-Effective for Low-Volume Production: Traditional manufacturing processes, such as injection molding, often require expensive molds and tooling. With 3D printing, you can produce low volumes of parts without the high upfront costs, making it an ideal choice for small batches or one-off designs.

Complex Geometries: 3D printing excels at producing parts with complex geometries that would be difficult or impossible to achieve using other manufacturing techniques. This capability is particularly valuable for industries requiring intricate designs and detailed features.

Material Versatility: 3D printing supports a wide range of materials, including plastics, metals, ceramics, and even composites, allowing you to choose the best material for your project’s requirements.

Reduced Waste: Traditional manufacturing often involves material wastage, especially with subtractive methods like milling or turning. Since 3D printing is an additive process, it only uses the material required for the part, reducing waste and promoting sustainability.

Enhancing the 3D Printing Process: Post-Processing and Finishing

While 3D printing itself creates high-precision parts, post-processing plays a crucial role in improving the quality, appearance, and functionality of the finished product. Some common post-processing techniques include:

Support Removal: Many 3D printed parts require support structures to hold them during printing. These supports are typically removed after printing, leaving behind a clean, fully formed part.

Polishing: Parts with a rough surface finish can be polished to achieve a smooth, aesthetically pleasing appearance.

Curing: Resin-based 3D prints may require UV curing to fully solidify and enhance material strength.

Get Started with XC Machining’s 3D Printing Services Today

We provide advanced 3D printing services that cater to various industries and applications all over the USA. Whether you need rapid prototypes, functional parts, or custom designs, our team is ready to help bring your ideas to life. We combine the latest 3D printing technology with years of experience to deliver precise, high-quality solutions that meet your specific requirements.

Contact Us Today to discuss your 3D printing project and find out how we can help you create innovative, customized solutions with speed, precision, and efficiency.

Let us help you take your ideas to the next level!