By means of shaping, carving, and assembly of wood, woodworking is a great art that lets you realize your thoughts. You know how annoying it can be, though, if you have ever battled uneven results, wasted material, or crooked cuts. Here, a wood laser cutting machine comes in rather handy. Wood laser cutting machines deliver stunningly accurate cuts. They follow your digital designs to the letter, ensuring each piece comes out just the way you envision it. Better yet, they minimize waste and make even intricate patterns a breeze.

In this article, we’ll talk about how a wood laser cutting machine truly elevates woodworking precision. We’ll go through the basics, explore key benefits like reduced waste and clean cuts, and offer practical tips you can apply right away.

Understanding Wood Laser Cutting Machine Basics

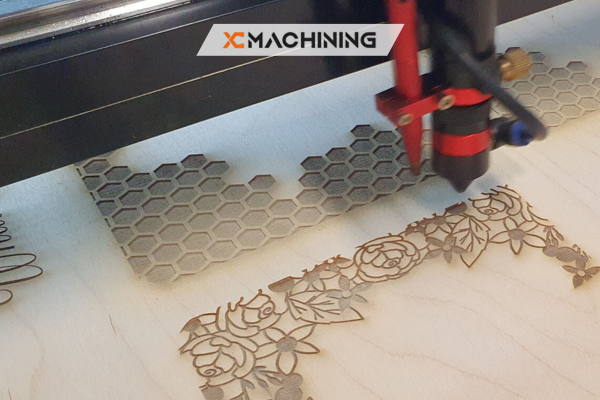

Although they have been around for some time, laser cutters are becoming more and more popular in woodworking and are altering the way we make bespoke furniture. If you have been depending on hand saws and chisels, the degree of detail and control lasers provide will astound you. This equipment slices through or engraves wood using a targeted laser beam, so enabling perfect shapes. In short, a wood laser cutting machine merges technology and craftsmanship to push woodworking to new heights.

Unmatched Accuracy

Laser beams offer near-microscopic precision, making it possible to cut curves, lines, and angles with laser-sharp accuracy. Because the system is controlled by a computer, every movement is carefully calculated. This eliminates the small slips that often happen with manual tools.

Intricate Designs

Creating elaborate patterns and tiny details is a breeze with a laser. From delicate etchings to complex inlays, you can let your imagination run wild. The laser cutting stainless steel fine focus ensures each swirl or flourish is consistent, giving your project a professional look.

Consistency And Repeatability

Once you’ve programmed your design, you can produce one, ten, or a thousand identical pieces. The system doesn’t get tired or make random mistakes. This consistency helps you deliver high-quality work every time, which is vital for large projects or small-batch productions alike.

Reduced Material Waste

Wood can be expensive, especially if you’re using rare or exotic species. Nothing feels worse than tossing away pricey scraps because of a miscalculation or an inaccurate cut. Thanks to the narrow kerf of a wood laser cutting machine, you waste far less wood. The laser beam is so thin that it only removes the smallest amount of material necessary to achieve a clean cut.

Fact: A “kerf” is the width of a cut made by a cutting tool. Traditional saws have a thicker kerf, which can add up to noticeable waste. Laser cutters, on the other hand, produce a much thinner kerf, saving valuable resources.

Another key advantage is the system’s predictability. Because you set exact dimensions before hitting the start button, the machine precisely follows your blueprint. You won’t see the typical trial-and-error that might come with hand tools. Over time, fewer “oops” moments add up to big savings.

Clean Cuts With Minimal Post-Processing

Few things are more time-consuming than having to sand and smooth edges after every cut. With traditional saws, rough edges are common. The friction of a saw blade can scorch the wood or leave jagged surfaces that require extra finishing steps.

A wood laser cutting machine cuts through the wood so cleanly that you might not need any additional smoothing. The laser’s heat seals the edges of many wood types, reducing fraying and splintering. You can go straight from cutting to assembly or apply finishes with much less sanding.

Here’s a quick comparison of how metal laser cutting design stacks up against other methods:

| Method | Edge Quality | Post-Processing Needs | Waste |

|---|---|---|---|

| Hand Saw | Often uneven | Frequent sanding needed | Moderate to high |

| Scroll Saw | Can be intricate | Some sanding, careful work | Moderate |

| Wood Laser Cutting Machine | Clean, smooth edges | Minimal sanding required | Very low (thin kerf) |

Suggestion: If you do see slight discoloration or charring after laser cutting, a gentle wipe or a light sanding can remove it. This minor step is still far easier than fixing an uneven or rough edge caused by a blunt saw.

Computer-Controlled Precision

If you’ve ever tried to replicate a design freehand, you know how easy it is to drift off the pencil line. Computer Numerical Control (CNC) laser cutters remove that worry. By using CAD (Computer-Aided Design) software, you have the freedom to create highly detailed plans.

Then, when you feed these digital files into your wood laser cutting machine, it reads each command with pinpoint accuracy. Whether you’re cutting swirling motifs or a simple rectangle, you get precisely what you designed on-screen. This level of control almost feels like cheating—only it’s not. It’s just technology making woodworking better.

Quick Tip: Many popular CAD programs let you adjust design parameters quickly. If you need to tweak a measurement by a few millimeters, you can do so in seconds without having to redraw an entire template by hand.

Practical Tips For Wood Laser Cutting Machine Users

Even the best machine won’t shine if you don’t use it properly. Here are some practical pointers to help you get the most out of your wood laser cutting machine:

- Experiment With Settings:

Different wood types respond differently to heat. Test your laser’s speed and power on small scraps first. - Focus on Ventilation:

Wood smoke and debris need proper airflow. A good ventilation system keeps your workspace clean and safe. - Keep the Lens Clean:

If the laser lens gets dirty, your cuts become less precise. Regular cleaning ensures better performance. - Use the Right File Format:

Most laser cutters work best with vector files like .AI, SVG or.DXF. Confirm which format your machine prefers. - Stay Organized With Labels:

When cutting multiple pieces, label or mark each one to avoid confusion during assembly.

Warnings Box: Never leave the laser cutter unattended while it’s running. Wood is flammable, and a spark can quickly escalate into a fire if you’re not vigilant.

Real-World Example And Renowned Brand Reference

For a real-world success story, consider small businesses that produce custom wooden puzzles. The puzzle pieces need to fit together perfectly, leaving no awkward gaps. By switching to a wood laser cutting machine, puzzle makers have reported a jump in overall quality and a huge cut in wasted plywood.

Info Box

If you’re looking for a trusted brand, XC Machining is a well-known name in the industry. They offer reliable machines that cater to different skill levels, from hobbyists to professional shops.

Beyond puzzles, handcrafted signage is another excellent example. Woodworkers create signs with fancy lettering or complex logos—jobs that would be tough with typical saws. Laser machines handle the fonts and shapes flawlessly, producing results that look straight out of a design studio.

Conclusion

A wood laser cutting machine is a true game-changer for anyone who works with wood. It helps you achieve amazing precision, tackle intricate designs, and replicate patterns without breaking a sweat. By reducing waste and simplifying post-processing, you can focus more on creativity and less on tedious cleanup.

If you’re tired of rough edges, wasted materials, or the frustration of repeating errors, it may be time to give laser technology a shot. The payoff is clear: smoother cuts, consistent results, and endless design possibilities that spark your imagination.

Remember, woodworking isn’t just about tools—it’s about turning your vision into reality. With a wood laser cutting machine, you’ll do just that while cutting down on errors and saving both time and money.

FAQ

- Do I need specialized design software to run a wood laser cutting machine?

Many laser cutters accept files created by common vector-based programs like Adobe Illustrator, CorelDRAW, or Inkscape. As long as you use the right file format (often .AI, .SVG, or .DXF), you should be able to run your designs without issues.

- Are laser cutters safe to use at home or in a small workshop?

Yes, but proper ventilation and supervision are crucial. Wood emits smoke and tiny particulates when cut, so a well-ventilated space is key. Also, never leave the machine running unattended, as wood is flammable and can catch fire if something goes wrong.

- Will a laser cutter handle all wood types?

Most standard woods (plywood, MDF, hardwoods like maple or birch) work well. Some woods contain oils or resins that can affect cutting quality. Always do a test run on a small piece, especially if you’re working with unusual or exotic species.

- Will I lose the “handmade” feel if I use a laser cutter?

This depends on your design approach. You can still incorporate hand finishes, unique textures, or special stains after laser cutting. The machine handles the precise cuts while your personal touch remains in the final sanding, assembly, and finishing.