Precision and safety are critical in the medical device industry, making ISO 13485 CNC machining a gold standard for manufacturers producing medical components. All parts made with this process are safe for patients, reliable, and can be traced back to their source.

The reliability of a medical CNC machining supplier depends on its certifications. Having ISO 13485 and 9001 certificates is more than just an achievement. They demonstrate that the supplier is committed to excellent practice and management.

They help to ensure that the company keeps meeting both government and customer requirements, especially while making medical devices. At the beginning, make sure to check the certifications of each supplier you are considering. This blog post is all about that.

How Does an ISO 13485 CNC Machining Work?

ISO 13485 is an international standard that provides requirements for companies making medical devices. It specifies that all documentation, processes, and risks must be managed properly.

Since CNC machining is used in the medical world, ISO 13485 guarantees that all parts are highly reliable. You should consider not only how clean something is, whether it’s safe for use by living beings, but also how well it’s made.

Why ISO 13485 Machining Is A Must-Have?

1. Medical Industry Demands Precision

When used in medicine, such medical instruments as tools, implants, and scanners must meet very strict standards. Whenever anything deviates, it could affect safety and effectiveness.

ISO CNC machining provides that precision through controlled and validated machining processes. Medical manufacturing relies on CNC machines, as these systems ensure all parts are repeated exactly, each time they are produced.

2. Built-In Compliance in Medical Part Production

Achieving compliance in medical part production is non-negotiable. Companies that utilize ISO 13485 are expected to fulfill both global regulations and what customers expect. This includes:

- Material traceability

- Inspection protocols

- Corrective and preventive actions (CAPA)

By aligning with this CNC machining type, manufacturers automatically adhere to the compliance framework necessary for regulatory audits.

Certified CNC Medical Manufacturers: A Competitive Advantage

Working with certified CNC medical manufacturers means partnering with suppliers who:

- Are audited by third parties

- Maintain updated documentation

- Follow continuous improvement programs.

- Provide traceable production histories.

The FDA estimates that 15% of all medical device recalls occur due to manufacturing problems. A certification is helpful in minimizing that risk.

Traceability in CNC Processes: Why It’s Critical

Traceability in CNC processes ensures that every part can be tracked from raw material to final inspection. If there is a problem with a product, its manufacturer can easily discover the cause and quickly recall those items.

This traceability includes:

- Batch numbers

- Operator data

- Machine settings

- Inspection reports

With ISO 13485 machining, all these records are securely maintained and accessible.

Key Benefits of ISO 13485 CNC Machining

1. Increased Product Reliability

By meeting rigorous medical machining quality standards, CNC manufacturers can ensure:

- Reduced defects

- Repeatable part accuracy

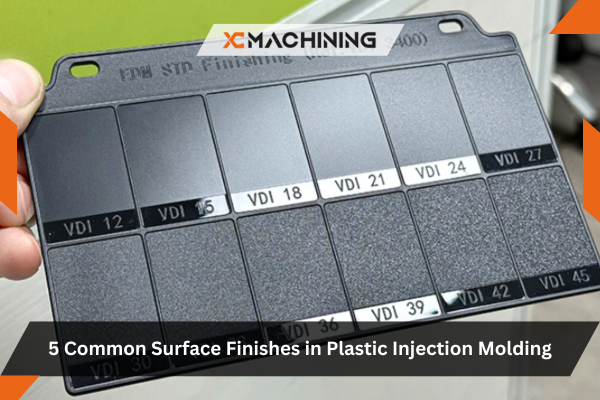

- Better surface finishes

- Improved mechanical performance

2. Faster Regulatory Approval

Products manufactured under ISO 13485 CNC machining are more likely to pass regulatory checks from bodies like the FDA and EU MDR. This reduces time-to-market.

3. Operational Efficiency

Routine procedures result in preventing errors, introducing time savings, and lower production costs, all at a similar standard of quality.

Real-World Applications of ISO 13485 CNC Machining

Orthopedic Implants

Because titanium and stainless steel implants are made by precision CNC machining, they adhere to the biological and size standards required by doctors.

Surgical Instruments

Sharpness and comfort in surgical instruments are achieved using advanced CNC machines.

Diagnostic Equipment

For imaging and testing purposes, the features inside advanced devices must be precise and spotless.

How to Choose a Reliable ISO Machining Partner

- Check Certification Status: Only work with certified CNC medical manufacturers with verifiable ISO 13485 credentials.

- Review Capabilities: Require your potential partner to equip itself with 3-, 4-, or 5-axis CNC machines, CAM/CAD implementation, and cleanroom abilities.

- Request Documentation: Ask for sample reports to see how the provider handles traceability in CNC processes and compliance records.

Why ISO 13485 CNC Machining is the Standard for Medical Components

Errors are not allowed in the medical sector, since they can have serious consequences. ISO 13485 CNC machining not only guarantees compliance but also ensures precision, safety, and quality across every product run.

Choosing certified CNC medical manufacturers who follow medical machining quality standards and prioritize compliance in medical part production is crucial. Add in robust traceability in CNC processes, and you’ve got a foundation for producing world-class medical devices.

Whether you’re developing next-generation implants or precision surgical tools, aligning with ISO CNC machining is a smart, future-ready decision.

FAQs

1. What industries require ISO 13485 CNC machining?

The primary reason for this is that device and life sciences companies generally require it most, mainly for parts that come into contact with patients.

2. Explain the difference between ISO 13485 and ISO 9001.

ISO 13485 appears in medical devices and extra requirements for risk management and item tracing are mentioned it, in contrast to ISO 9001.

3. Is it possible that every CNC manufacturer is ISO 13485 compliant?

No. Only those specializing in medical device production and who undergo third-party audits can be considered certified CNC medical manufacturers.

4. What is the role of traceability in ISO 13485 CNC machining?

Traceability in CNC processes allows every part to be tracked, helping manufacturers identify defects, maintain accountability, and comply with regulations.

5. How will a manufacturer be affected if it does not meet the requirements of ISO 13485?

There is a chance they would face product recalls, fines, and losing accreditations. Patients’ safety might be at risk.