High-Volume Production takes advantage of modern tools and equipment that are more consistent, and faster raising efficiency within a variety of manufacturing industries.

Robotic Automation

Robotics is particularly fundamental in mass production to simplify repetition, and to enhance uniformity. Robots have the capability of doing work at a high pace and in the most precise manner; tasks including; assembly, welding, painting and packaging work. They can be active every twenty four hours greatly enhancing the efficiency of the productions and minimising human mistakes.

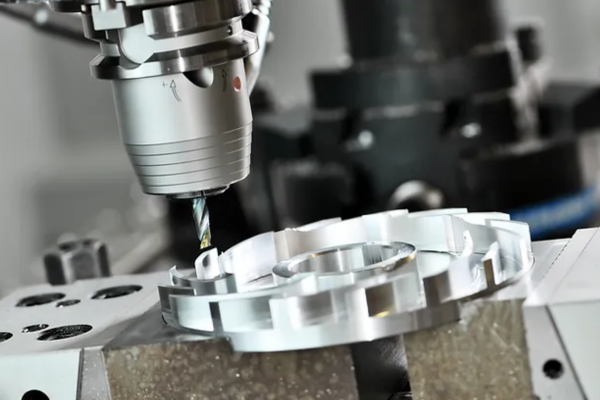

CNC Machines

Precision machining on high-volume productions is carried out using the CNC machines. The machines receive instructions to perform intricate cutting, holes, shapes with high precision and accuracy to reduce wastage of materials in the production of all the units. CNC is a common technology in automotive, aerospace, and electronics industries in an effort to ensure tighter tolerances are upheld and that production levels have been increased.

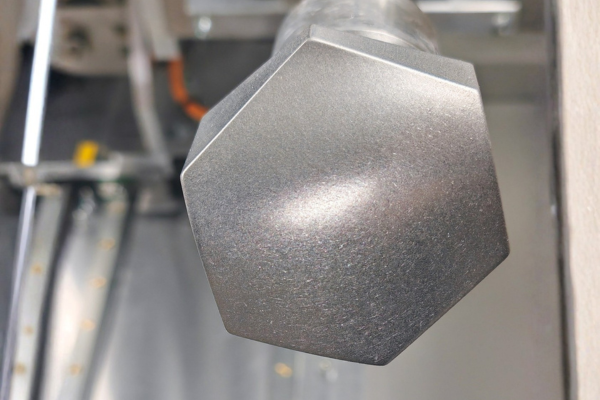

Additive Manufacturing (3D Printing)

Traditionally used in prototyping, 3D printing is now seeing some successes in high-volume production as a method of producing customized parts and tooling. It can be used to fabricate in less time to have prototypes, as well as rectify geometries of intricate parts which could be hard or expensive to print using conventional manufacturing techniques.

IoT and Smart Sensors

IoT technology can integrate machines and devices on a production floor to remotely track performance and conditions in real-time. Manufacturers can capture anomalies at earlier stages by installing sensors to collect data on variables (temperature, humidity, vibration). The outcome is predictive maintenance and reduced production downtimes resulting in increased production efficiencies.

AI and Machine Learning

AI and machine learning are transforming high-volume manufacturing decisions through real-time optimization of the processes. Such technologies are used to predict failures, detect inefficiencies, as well as automate quality control using the production data analysis. Its IQ can also be used to optimize machine settings using previous performance as a guideline in order to keep the quality of the product and cut down on waste.

Supply Chain Management software

Supply chain management software is a type of more developed software that helps to manage and to optimize stock, the filling of orders, and transportation. It eliminates delays due to unreadiness of materials and components as the technology would have them ready when required.

What Are The Challenges in High-Volume Production?

In high volume production, a number of issues must be carefully considered to maintain efficiency, quality and ease of manufacture.

Scalable Consistent Quality

Consistency of quality in the products produced becomes an uphill task since more is produced. Ingredients need to be carefully weighed and checked since even small inaccuracies may be multiplied with large batches of food being processed, and quality control methods and checking must be rigorous to eliminate flaws. The ability to keep high volumes the same in quality of material and accuracy of measures is sometimes prone to inconsistencies.

Efficiency Vs. Accuracy

Speed can never be ignored in a high-volume manufacturing environment; at the same time, greater efficiency depends on a firm commitment to accuracy. Automated systems are great, but calibration errors or hardware failures can interfere with the whole system, it is not easy to achieve both efficiency and precision simultaneously.

Workforce Skill Gaps

The reliance on automation and high technologies grows, and it is only the skillful workers that should be able to operate and maintain high-tech machinery. Nevertheless, there are problems with the availability rates of such skilled personnel, which result in a difficult time in the recruitment and training of employees able to thoroughly apply the concepts of robotics, AI, and data management.

Technology Integration and Upgrades

When faced with the task of implementing the new technologies without disrupting established high-volume production lines, there are challenges of its own. Older systems are not compatible with new automation tools and thus could result in costly downtimes and maintenance. Replacing gears is also very expensive and therefore manufacturers face the challenge of trying to keep up with technological changes.