What This Guide Covers

Choosing the right CNC milling software can dramatically impact your shop’s productivity, part quality, and profitability. After 12 years programming CNC machines and implementing software across diverse manufacturing operations, I’ve seen firsthand how the right software cnc milling solution can reduce programming time by 60%, eliminate costly collisions, and enable complex geometries previously thought impossible.

In this comprehensive guide:

- Essential CNC milling software categories and functions

- Top CNC milling machine software options for 2025

- How to evaluate and select software for your needs

- CNC milling simulation software capabilities

- Real-world implementation experiences

- Cost-benefit analysis and ROI considerations

Whether you’re running a one-person job shop or managing a production facility with dozens of machines, understanding modern CNC milling software options helps you make informed decisions that impact your competitiveness and bottom line for years to come.

Table of Contents

Understanding CNC Milling Software Categories

Last year, a machine shop owner came to me frustrated. He’d invested $8,500 in CNC milling software that promised to “revolutionize” his operation, but after 6 months, his programmers were still creating G-code manually because the software was too complex and didn’t match their workflow. We evaluated his actual needs, switched to different software costing $3,200, and his programming time dropped 40% within two months.

That experience exemplifies why understanding software categories and matching them to your specific requirements matters more than buying the “best” or most expensive option.

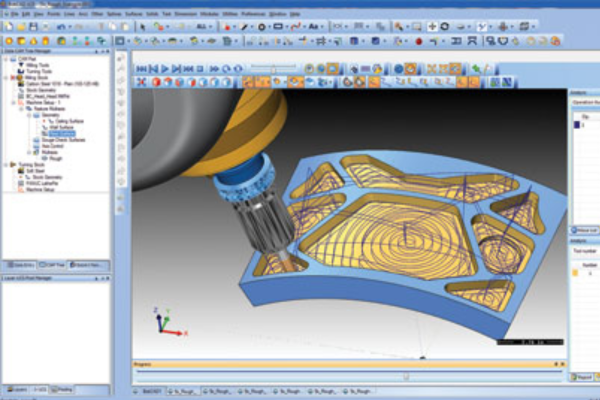

CAM Software (Computer-Aided Manufacturing)

Primary function: Converts 3D CAD models into tool paths and G-code instructions that CNC machines execute.

Core capabilities:

- Tool path generation (roughing, finishing, drilling, threading)

- Multi-axis machining support (3-axis, 3+2, full 5-axis)

- Material removal simulation

- Post-processor customization for specific machines

- Tool library management

- Feeds and speeds optimization

Real impact: Professional CAM software is the foundation of modern CNC milling operations. A programmer who can generate complex tool paths in 2 hours manually might accomplish the same task in 20 minutes with good CAM software—a 6x productivity improvement.

CNC Milling Simulation Software

Primary function: Virtual machining simulation that verifies tool paths detect collisions, and optimizes cutting conditions before running on the actual machine.

Critical capabilities:

- Realistic material removal simulation

- Collision detection (tool, holder, spindle, workpiece, fixtures)

- NC code verification

- Machine kinematics simulation

- Cutting force analysis

- Cycle time estimation

Why it matters: One collision can cost thousands in broken tools, damaged workpieces, and machine downtime. CNC milling simulation software catches these issues virtually, where mistakes cost nothing.

Real savings: A aerospace manufacturer I consulted with prevented 23 collisions in their first year using simulation software—events that historically averaged $3,800 each in damage and downtime. The simulation software paid for itself in the first month.

CAD/CAM Integrated Solutions

Combination approach: Some software packages integrate CAD design and CAM programming in a single environment.

Benefits:

- Seamless design-to-manufacture workflow

- No file translation issues

- Associative machining (tool paths update with design changes)

- Unified user interface

Considerations:

- Often more expensive than standalone CAM

- May require learning new CAD system

- Not all shops need integrated CAD

Top CNC Milling Software Options for 2025

Based on extensive hands-on experience and industry feedback, here are the leading software cnc milling solutions:

| Software | Best For | Price Range | Key Strengths | Learning Curve |

|---|---|---|---|---|

| Mastercam | General machining, production | $5,000-$30,000+ | Industry standard, excellent support, vast user base | Moderate |

| Fusion 360 | Small shops, hobbyists, startups | $545/year (or free hobbyist) | Affordable, CAD+CAM integrated, cloud-based | Easy-Moderate |

| SolidCAM | SolidWorks users, production | $8,000-$25,000+ | Seamless SolidWorks integration, iMachining technology | Moderate |

| Siemens NX CAM | Aerospace, complex 5-axis | $10,000-$50,000+ | Advanced capabilities, enterprise solutions | Steep |

| ESPRIT | Complex multi-axis, Swiss machining | $10,000-$40,000+ | Excellent 5-axis, simulation included | Moderate-Steep |

| GibbsCAM | Production, ease of use | $6,000-$20,000+ | Fast programming, user-friendly | Easy-Moderate |

| Edgecam | 2.5D to 5-axis, waveform roughing | $7,000-$25,000+ | Solid all-around capabilities | Moderate |

| hyperMILL | High-end 5-axis, complex surfaces | $15,000-$50,000+ | Premium 5-axis toolpaths, excellent finishing | Steep |

| BobCAD-CAM | Budget-conscious, small shops | $1,000-$8,000 | Affordable entry point, decent capabilities | Easy-Moderate |

| SprutCAM | Mill-turn, versatile | $3,000-$15,000 | Good value, multiple processes | Moderate |

Detailed CNC Milling Software Analysis

Mastercam: Industry Standard

Why it dominates: With over 40% market share in North America, Mastercam is the closest thing to an industry standard in CNC milling software.

Strengths:

- Extensive training resources and massive user community

- Post-processors available for virtually every machine

- Proven reliability in production environments

- Excellent technical support

- Regular updates and improvements

- Add-ons for specialized operations

Considerations:

- Higher cost (but often justified)

- Perpetual license model (not subscription)

- Requires Windows operating system

Real experience: I’ve implemented Mastercam in shops ranging from 2 machines to 50+. The learning curve is reasonable, and productivity gains typically justify the investment within 8-12 months for production environments.

Fusion 360: The Game-Changer

Disrupting the market: Autodesk’s cloud-based CAD/CAM solution has transformed accessibility to professional-grade CNC milling software.

Revolutionary aspects:

- $545/year subscription (vs. thousands for competitors)

- Free for hobbyists, startups, and educators

- Integrated CAD and CAM in one package

- Cloud-based collaboration

- Regular updates included

- Works on Mac and Windows

Limitations:

- Cloud dependency (internet required)

- Less advanced than high-end solutions for complex 5-axis

- Post-processor library smaller than Mastercam

- Some features still maturing

Perfect for:

- Startups and small shops

- Hobbyists and makers

- Companies wanting integrated CAD/CAM

- Shops with limited software budgets

Real adoption: I’ve seen established shops add Fusion 360 licenses for $545/year as secondary systems while maintaining Mastercam for complex work. The low cost makes experimentation risk-free.

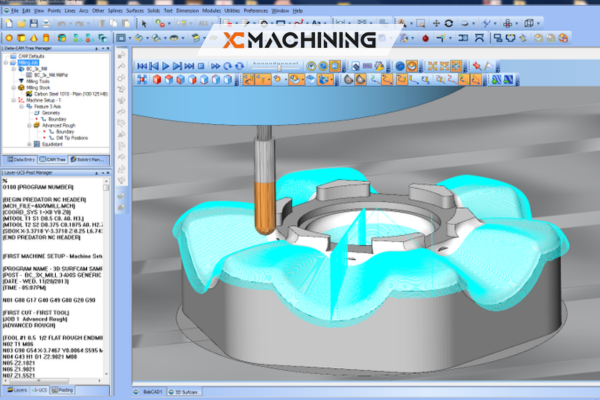

SolidCAM: SolidWorks Integration

Unique value: For shops already using SolidWorks for design, SolidCAM provides seamless integration.

Key features:

- Operates entirely inside SolidWorks interface

- Associative machining (design changes update tool paths)

- iMachining technology (intelligent roughing strategies)

- Single-window workflow (design and manufacturing together)

iMachining advantage: This proprietary technology optimizes tool paths for consistent chip load, reducing cycle time 30-70% while extending tool life. It’s genuinely innovative and delivers measurable results.

Considerations:

- Requires SolidWorks license

- Premium pricing

- Learning curve if unfamiliar with SolidWorks

High-End Solutions (Siemens NX, hyperMILL)

When you need the best:

- Complex 5-axis simultaneous machining

- Aerospace or medical device manufacturing

- Impeller and turbine machining

- Die and mold applications with complex surfaces

Reality check: These systems cost $15,000-$50,000+ per seat, require extensive training, and are overkill for most shops. But for complex work, they’re worth every penny.

CNC Milling Simulation Software

Simulation deserves special attention because it prevents disasters:

Standalone Simulation Solutions

VERICUT by CGTech:

- Industry-leading NC code verification

- Detects collisions, gouges, and other issues

- Machine simulation with accurate kinematics

- Optimization features reduce cycle time

- Price: $10,000-$30,000+

- Worth it for high-value parts and complex setups

NCSimul:

- Comprehensive simulation and optimization

- European market leader

- Excellent user interface

- Price: $8,000-$25,000+

Simulation benefits quantified:

- One prevented collision: $2,000-$10,000 saved

- Optimized feeds/speeds: 10-30% cycle time reduction

- Confidence in complex programs: Priceless

- Insurance against catastrophic crashes: Essential for expensive parts

Built-In Simulation

Most modern CAM software includes simulation capabilities:

Basic simulation (included in most CAM):

- Material removal visualization

- Simple collision checking

- Tool path verification

Advanced simulation (premium features):

- Accurate machine kinematics

- Holder and fixture collision detection

- Cutting force analysis

- Optimization recommendations

Selecting the Right CNC Milling Machine Software

Assessment Framework

Step 1: Define your requirements

Machine capabilities:

- How many axes? (3-axis, 4-axis, 5-axis?)

- Machine control type? (Fanuc, Haas, Siemens, Heidenhain?)

- Multiple machines? (Need post-processors for each)

Part complexity:

- Simple 2.5D parts? (Basic software sufficient)

- 3D contoured surfaces? (Intermediate software)

- Complex 5-axis? (Advanced software essential)

Production volume:

- Prototype/job shop? (Flexibility matters)

- Production runs? (Efficiency and automation critical)

- Mix of both? (Versatile solution needed)

Budget reality:

- Software cost

- Training time and cost

- Annual maintenance/subscription

- Hardware requirements

Step 2: Evaluate options

Trial periods:

- Most vendors offer 30-day trials

- Actually use software with your parts during trial

- Involve the people who will use it daily

- Test post-processor with your specific machines

Training availability:

- Official training courses

- Online resources and tutorials

- User community size

- Local support availability

Step 3: Calculate ROI

Programming time savings:

Current: 4 hours average per part × $75/hour = $300

With new software: 1.5 hours × $75/hour = $112.50

Savings per part: $187.50

Annual parts programmed: 200

Annual savings: $37,500

Software cost: $8,000

ROI period: 2.5 months

Additional value:

- Collision prevention

- Faster cycle times (optimized tool paths)

- Reduced scrap (simulation catches errors)

- Ability to take on more complex work

Implementation Best Practices

Training Investment

Critical success factor: Budget 40-80 hours of training per programmer.

Training approaches:

- Formal classes (2-5 days intensive)

- Online courses (self-paced)

- On-site training (customized to your work)

- Ongoing learning (never stops)

Reality: Shops that skimp on training never realize software’s full potential. Programmers revert to old methods, and expensive software sits underutilized.

Post-Processor Development

Often overlooked: Generic post-processors rarely work perfectly with your specific machine configuration.

Investment needed:

- Customization for your machine specifics

- Testing and verification

- Ongoing refinement

Best practice: Budget $1,500-$5,000 for professional post-processor customization. A good post-processor is as important as the CAM software itself.

Workflow Integration

Gradual transition:

- Start with simpler parts

- Run programs in single-block initially

- Verify dimensions carefully

- Build confidence before complex work

Parallel approach:

- Initially program parts both old way and new way

- Compare results

- Identify learning opportunities

- Gradually increase reliance on new software

Common Mistakes to Avoid

Mistake #1: Choosing Based on Price Alone

The trap: Selecting the cheapest option without considering capabilities and workflow fit.

Reality: A $1,000 software package that doesn’t match your needs wastes $1,000. An $8,000 package that reduces programming time 50% pays for itself in months.

Mistake #2: Ignoring Training

The trap: Buying software and expecting programmers to figure it out.

Reality: Modern CAM software is powerful and complex. Without proper training, you’ll use 20% of capabilities and wonder why you bothered.

Mistake #3: Over-Buying Capabilities

The trap: Purchasing 5-axis software when you only have 3-axis machines.

Reality: Match software to your actual needs today, with reasonable future growth consideration.

Mistake #4: Underestimating Post-Processor Importance

The trap: Assuming generic post-processors will work fine.

Reality: Machine-specific quirks, tool changers, and control differences require customized post-processors for reliable results.

Future Trends in CNC Milling Software

AI and machine learning:

- Automatic feature recognition

- Intelligent tool path optimization

- Predictive tool wear monitoring

- Self-optimizing cutting parameters

Cloud-based solutions:

- Collaborative programming

- Centralized data management

- Anywhere access

- Subscription models

Simulation and digital twins:

- Real-time monitoring

- Predictive maintenance

- Process optimization

- Virtual commissioning

Integration with Industry 4.0:

- IoT connectivity

- Data analytics

- Automated decision-making

- Smart factory integration

Conclusion

Selecting the right CNC milling software is one of the most important technology decisions your shop will make. After 12 years working with virtually every major software cnc milling solution, I’ve learned that the “best” software is the one that matches your specific needs, fits your budget, and your team will actually use effectively.

For most general machine shops, Mastercam remains the industry standard—proven, reliable, and well-supported. For budget-conscious operations or those wanting integrated CAD/CAM, Fusion 360 offers incredible value at $545/year. For SolidWorks users, SolidCAM’s seamless integration and iMachining technology deliver measurable productivity gains. For complex 5-axis and aerospace work, high-end solutions like Siemens NX or hyperMILL justify their premium prices.

Don’t neglect CNC milling simulation software—whether standalone like VERICUT or integrated into your CAM package. Simulation prevents costly collisions, optimizes cutting conditions, and builds confidence in complex programs. The insurance value alone often justifies the investment.

Key takeaways for selecting CNC milling machine software:

- Match to your needs: Don’t over-buy or under-buy capabilities

- Try before buying: Use trial periods with real parts

- Invest in training: 40-80 hours per programmer minimum

- Customize post-processors: Generic rarely works optimally

- Calculate real ROI: Factor programming time, collision prevention, and cycle time reduction

- Consider support: Vendor support quality matters long-term

- Plan for growth: Some future capability anticipation is wise

The right software investment pays dividends for years through faster programming, fewer errors, optimized cutting, and the ability to take on more complex, profitable work. The wrong choice costs time, money, and frustration.

Start with clear requirements, thoroughly evaluate options, invest in proper training, and choose software that fits your workflow. Your programmers, your bottom line, and your competitiveness will thank you.