Waterjet cutting relies on a combination of high-pressure pump systems, CNC motion control, and advanced nozzle technology to deliver precise, cold-cutting performance across a wide range of materials.

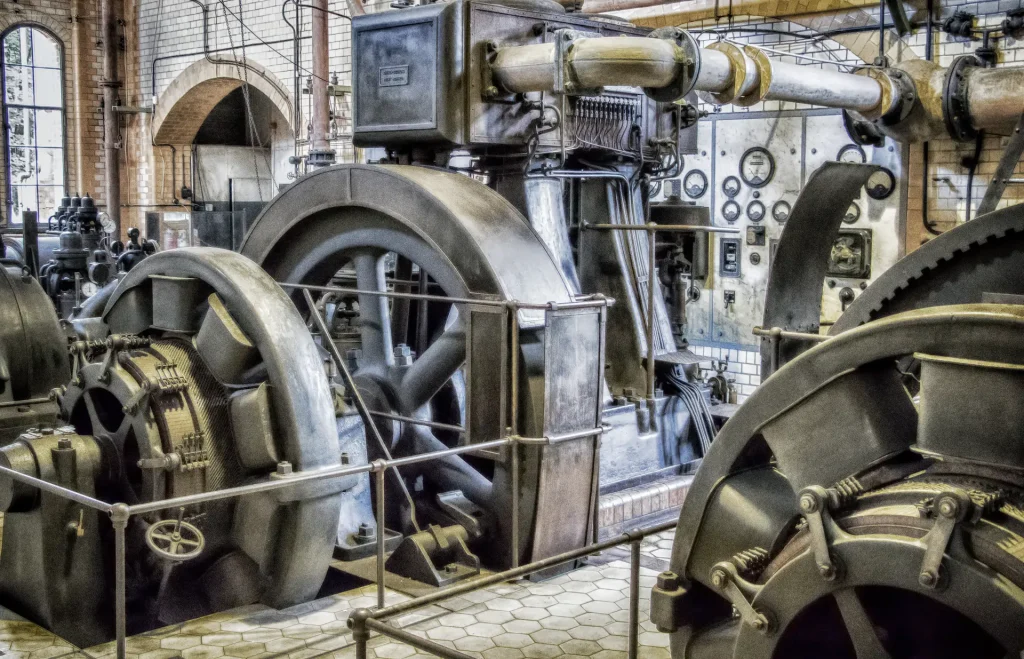

High-Pressure Pump Technology

The core of any water jet cutting tool involves a high-pressure pump, which creates some pressure in the range of 60,000 to 90,000 PSI. It is this high pressure that makes common water turn into a strong cutting object. Pumps used are basically of two types, an intensifier pump, utilizing hydraulic pressure and direct drive pump, which is mechanized in order to be efficient and small.

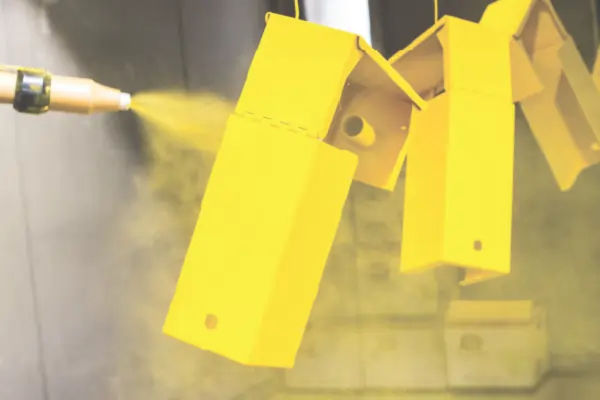

Abrasive Jet Cutting System

When it is used to cut hard materials such as metal, stone, or glass, abrasive (typically garnet) particles are added to the water stream. This makes the waterjet an abrasive jet that cuts the tough materials cleanly. The abrasive is blended in a stove and is thus channeled through an opening to ensure accurate cutting without heat.

Purer Water Jet Cutting

In cutting soft or sensitive materials like rubber, foam or a textile, pure water cutting is applied where no abrasive is used. It makes clean, precise cuts and it does not contaminate the material as well. It is a preferred method of processing that is non-abrasive in nature.

CNC Motion Control System

The CNC (Computer Numerical Control) system used to control the cutting head enables the head to move with exact programmable moves. The system provides precision cutting according to the digital CAD files and is able to work on complicated figures and narrow tolerances. Another way it can be used is to automate production to achieve high quantity production.

Nozzle Assembly and Assembly Cutting Head

The action of cutting occurs at the nozzle and it consists of a small orifice (usually of ruby, sapphire or diamond), and a mixing tube. The nozzle used in abrasive cutting is also used to channel the abrasive particles along with the water stream. The waterjet is made sure to be focused and accurate when used in terms of the configuration of the nozzle.

Integration of CAD/CAM Software

The waterjet systems are generally incorporated into CAD/CAM software to operate manufacturing and design processes. Engineers have the capability of importing digital drawing, optimizing of cutting paths and efficient nesting of parts to save on waste of materials. This integration simplifies the entire procedure between design and final part.

Z-Axis Control and Height Sensors

Advanced waterjet systems include automatic height sensors and Z-axis control to maintain the correct distance between the nozzle and the material. It ensures consistent cutting depth, compensates for uneven surfaces, and prevents collisions. It’s especially useful when working with warped or thick materials.

Material Handling and Support System

Most machines will have built into them a material handling process such as gantry system, conveyor or vacuum table as a process to increase their efficiency. These fixtures aid in stabilizing the material in the course of cutting and they make loading and unloading of parts simpler. Cutting tables that are water filled also make it less noisy, debrisk and cool the material.

What Are the Most Common Waterjet Cutting Mistakes?

Waterjet cutting mistakes like improper abrasive selection, misaligned nozzle height, and unsecured materials can lead to inaccurate cuts, equipment wear, and production inefficiencies.

Use of Wrong Abrasive

The wrong abrasive type or grit may vastly diminish your cutting efficiency and impact the surface of parts cut. A good example here is that the finer abrasives will be needed in detailed work whereas the coarse abrasives are more suited to thicker or softer materials.

Incorrect Nozzle Height

It is imperative to have the right distance between the nozzle and the piece of work. Both splash-back or possible damage can be created by a nozzle too near, and cutting precision and edge quality will be sacrificed by an over-distant nozzle.

Ignoring Taper Compensation

When using waterjet cutting, tapered edges on thicker materials are possible. You have to be careful to not set your machine up or design your machine without considering taper, as these parts will not have the correct dimensions.

Failing to Secure the Material

Unless the material is well clamped or weighed down the material may move during the cutting. Even such a little movement is possible to upset the line of cut and spoil the whole piece of work.

Skipping Preventive Maintenance

Your pump, nozzle, filters and abrasive delivery system needs regular maintenance. Failure to observe it may lead to inconsistent cuts, pressure loss, or sudden down-time which will cause time wastage and additional expenses in your project.