Choosing the right manufacturing process can be overwhelming even for experts. Though vacuum casting and injection molding are distinct processes, they have certain similarities, sometimes making choosing difficult.

Using the wrong manufacturing technique may have a huge financial impact on your company. This makes it essential to have an in-depth knowledge manufacturing process before settling for any. As a result, this article compares vacuum casting vs injection molding and discusses the key differences between the two processes.

What is Vacuum Casting?

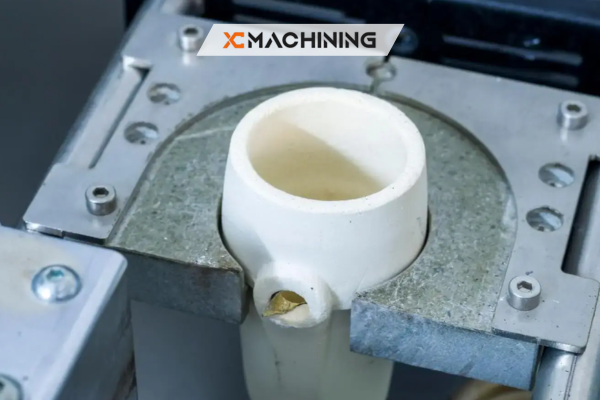

Vacuum casting, or polyurethane casting or urethane casting, is a manufacturing process that pulls molten plastic materials into a mold under a vacuum to create a part. The process of vacuum casting is easy. It involves manufacturing the master mold using CNC machining, 3D printing, or stereolithography.

After creating the silicone mold and removing the master mold, fill it with the material in a vacuum casting vs injection molding chamber with a predetermined temperature. Allow it to cool, and remove from the mold. Carry out post-production finishes as needed and repeat the process based on the number of desired parts. Note that the master mold determines the quality of the finished part. In addition, it is important to deburr the casting parts for the best surface texture and quality.

What is Injection Molding?

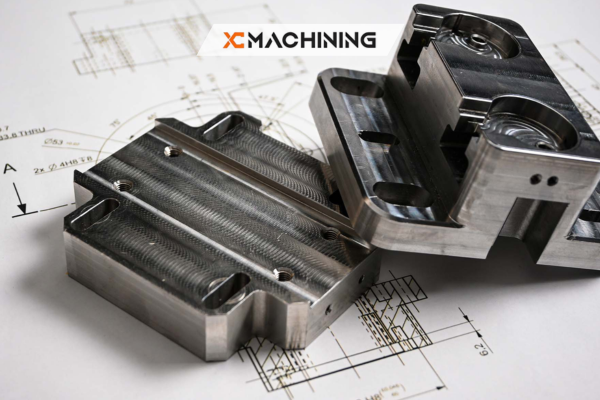

Injection molding is a plastic-forming process that forces liquified material into a pre-manufactured mold. This low-velocity liquid takes the shape of the mold as it cools. Four distinct stages define injection molding- clamping, injection, cooling, and ejection.

The clamping stage keeps the mold in place and opens it up at the right times. After, the injection unit receives the plastic granules through the hopper before melting them and supplying the liquified material into the mold. The molten plastic begins to solidify after it comes in contact with the interior part of the mold. After sufficient cooling, you can open the mold to eject the final part. Proper mold design prevents defects and is important for undercut injection molding.

Key Differences Between Vacuum Casting vs Injection Molding

Vacuum Casting vs Injection Molding are both semi-automated manufacturing processes. They both use a mold for fabricating parts. However, they differ in the following ways:

Cost

Injection molding cost, when compared to vacuum casting, is high. The amount one would spend on buying and setting up a standard injection molding machine may range between $50,000-$200,000. On the other hand, vacuum casting is less expensive because it uses silicone molds. This type of mold is cheaper and easier to manufacture when compared to the metal mold injection molding technique.

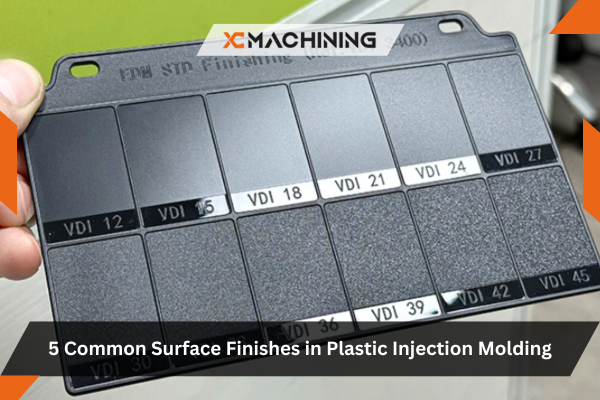

Tolerance and Precision

Injection molding achieves industries’ tight tolerances and creates parts with high accuracy and precision. However, vacuum casting vs injection molding tolerance level is lower. The fact that the silicon mode shrinks about 2% after curing makes the tolerance level of vacuum casting loose. You can minimize this shrinkage by closely monitoring the mold temperature and curing time.

Material Compatibility

Injection molding is compatible with various materials, including polymers, engineering plastics, and polymer blends. On the other hand, vacuum casting has material limitations. This manufacturing process works best with polycarbonates and rubbers because they are flexible.

Tooling Lifespan

The tooling lifespan of both processes varies and depends on the material makeup and maintenance. Injection molds are made from strong metals such as aluminum or steel. As a result, they have a long lifespan. Aluminum molds can make 2,000 – 10,000 parts, while steel molds have a better lifespan as they can make 100,000 parts before they wear out. Vacuum Casting vs Injection Molding, on the other hand, have a shorter life span because silicone becomes brittle with continuous usage. Usually, they can make 20-30 parts before they wear out.

Waste Generation

Injection molding generates more waste than vacuum casting vs injection molding. Wastes may come from sprues or runners when filling in the plastic material. These, as well as defective parts, can be recycled if uncontaminated. The only waste vacuum casting generates is the excess on the finished part.

| Parameters | Vacuum Casting | Injection Molding |

| Material Compatibility | Polycarbonates and rubbers | Polymers, engineering plastics, and polymer blends |

| Cost | Less expensive | More expensive |

| Tolerance and Precision | Less tight | Tight |

| Tooling Lifespan | Short | Long |

| Waste Generation | Less waste | More waste |

How To Choose Between Vacuum Casting and Injection Molding?

There is no standard approach to choosing the right manufacturing method in vacuum casting vs injection molding. Consider the following before using vacuum casting or injection for your project.

Production Volume

The intended production volume is a key factor when choosing a manufacturing method. Vacuum casting is better for prototyping and low-volume production, while injection molding is more suitable for high-volume production. Injection molding is suitable for large-volume parts production because its molds have longevity. On the other hand, vacuum casting produces fewer parts, with silicone molds capable of making around 30 parts before they wear out.

Lead Time

Before choosing a manufacturing process, one needs to consider the lead time. Vacuum Casting vs Injection Molding is better in terms of production time. It is easier and faster to manufacture silicone molds than molds made of aluminum or steel. This advantage makes vacuum casting ideal for time-sensitive operations.

Part Size

The size of the part may also influence your decision. The silicone mold of vacuum casting has a size limitation and is better suited for medium to small-sized parts. For larger parts, go for injection molding. The size of the mold has no limit. However, you will need a larger injection molding machine to accommodate the mold size.

Applications

Vacuum Casting vs Injection Molding both have diverse industrial applications. Choosing the right one for your project may depend on the industry. Injection molding has applications in medical devices, packaging solutions, automotive components, and aerospace industries. Most of these parts are complexly shaped and must be accurate for functionality. Vacuum casting produces parts with fine details in consumer electronics, medical prosthetics, artworks, and automotive accessories.

XC Machining Helps Your Vacuum Casting and Injection Molding Projects

After deciding what to manufacture, choosing the appropriate manufacturing technique is the next step. For accuracy, choose a professional manufacturer for your project that is reliable. XC Machining is the right choice for all your vacuum casting vs injection molding projects. From prototyping to mass production, we have experts who always offer cost-effective machining solutions. Our injection molding and vacuum casting specialists help you use the right process and material to get high-quality products. Just upload your CAD files and get a quote today!

Conclusion

When comparing vacuum casting vs injection molding, no one is superior. The choice depends on the specific requirements of your application. What is the key difference between vacuum casting and injection molding? How do I choose the right manufacturing method? We hope this article has answered all your questions.

FAQs

How do I prevent injection molding defects?

Injection molding defects, including warping, air pockets, and weld lines, can affect the functionality of a part. They may occur due to insufficient mold pressure or uneven cooling of the final parts. To prevent this, increase the mold pressure and injection speed so the materials cool uniformly in the mold.

Is vacuum casting the same as vacuum forming?

Vacuum casting and vacuum forming do not mean the same thing. Vacuum forming creates complex shaped parts using a plastic sheet as the starting material. It involves heating the material before using a vacuum to suck it into a mold. The vacuum casting process differs by pouring the material into the mold and removing the final part after curing.

What is the size limit for injection molding?

In theory, there is no limit to the size of an injection molded part. However, most Vacuum Casting vs Injection Molding machines can accommodate a four-by-four inches part conveniently. Going for larger parts will require bigger and more expensive machines.