Are you frustrated trying to find the perfect partner to create high-quality parts for your business? Maybe you’ve scoured the globe in search of reliable machining solutions and still feel uncertain. If you’re nodding your head, don’t worry—you’re not alone. Many entrepreneurs and product designers share the same struggle of finding the right CNC machining manufacturer.

In the following sections, we will explore in detail how local CNC Machining can be a game-changer for your business. You’ll learn how proximity, quality assurance, customization, and strong partnerships contribute to smoother operations and happier customers.

Local CNC Machining Manufacturer: Quick Overview

Choosing a local CNC machining manufacturer offers multiple benefits, such as shorter turnaround times, personalized support, and a chance to build long-term relationships. You’ll also reduce shipping costs and avoid communication barriers. By opting for a nearby facility, you’re more involved in every stage of production, leading to better results for your business.

Faster Production Timeline

Local machining centers are just a phone call or a short drive away, which means it’s easy to stay updated on progress. If a problem arises, quick in-person visits help solve issues. This closeness keeps production on track and prevents missed deadlines.

Clearer Communication

Local language, shared cultural references, and real-time dialogue streamlines your discussions. Misunderstandings drop significantly when you speak the same language or live in the same region. When you can pick up the phone or visit, complex details become clearer and lead to flawless parts.

Stronger Partnerships

Forming a relationship with a local manufacturer often goes beyond mere transactions. It can develop into a trusted partnership where both businesses invest in each other’s success. This deeper connection fosters mutual support, loyalty, and the chance for collaborative innovations down the road.

Better Quality Control

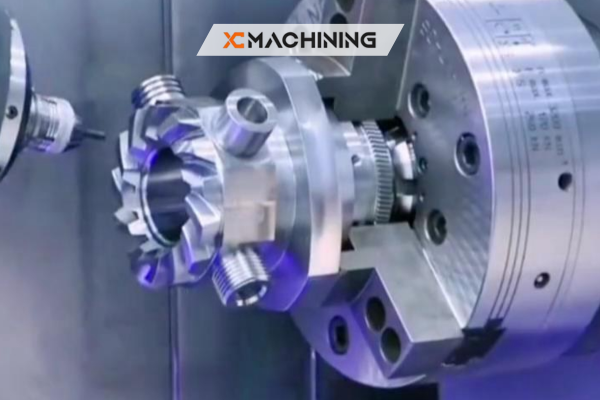

When your CNC machining manufacturer is nearby, you can easily drop in to check on production. It’s almost like having an extended in-house team that you can visit anytime. You see firsthand how your parts are made, reducing the chance of hidden mishaps.

Regular quality audits are simpler, too. Instead of relying on photos or videos from a distant location, you get to inspect parts in person. This hands-on approach quickly spots any errors and allows you to give immediate feedback, which saves time and money.

Reduced Lead Times

One big advantage of staying local is faster lead times. Shipping from overseas can get stuck in customs or delayed by unexpected events, like natural disasters or political unrest. Those delays can throw a wrench in your supply chain plans.

With a local CNC machining manufacturer, you can often get parts in days rather than weeks. You skip the long-haul shipping and cut back on the back-and-forth communications. Production becomes smoother and more predictable, letting you forecast demand with greater accuracy.

Lower Shipping and Logistics Hassles

International shipping can be costly, time-consuming, and full of paperwork. You also risk damage during long transit times and potential border issues. All these headaches can ramp up your budget and stretch your timelines.

By choosing a local CNC machining manufacturer, you drastically reduce shipping distances. Logistics have become simpler, fees have become more straightforward, and your parts have arrived quicker. You can even pick them up yourself if needed, further trimming costs and boosting efficiency.

Personal Relationship and Face-to-Face Meetings

When you can visit your CNC fixture in person, you forge a strong bond. Phone calls and emails are great, but there’s something special about face-to-face time. You get to see their workspace, meet the people handling your parts, and establish genuine rapport.

This personal touch can lead to enhanced trust and loyalty. Your manufacturer becomes more invested in your success. Meanwhile, you gain confidence that your parts are in good hands and that your specific needs won’t get lost in translation.

Supporting Local Economy

Working with a local CNC machining manufacturer isn’t just good for you; it’s also great for your community. Your money stays within the local economy, supporting jobs and growth. This can create a positive ripple effect, benefiting other local businesses and families too.

Plus, you might find more opportunities for local partnerships. Maybe you can team up for joint marketing or special events. Strengthening these local ties can give your brand a reputation for caring about the community and investing in regional development.

Transparent Cost Structure

When dealing with overseas manufacturers, hidden fees can appear unexpectedly. You might face extra shipping charges, customs duties, or currency exchange fluctuations. All those add-ons can blow up your initial budget estimates in a flash.

Locally, the cost structure is usually more transparent. You’re less likely to encounter random price hikes, especially if you can do direct in-person negotiations. You see exactly what you’re paying for and can make financial decisions with confidence and clarity.

Quick Turnaround for Prototyping

Product development often involves metal prototypes to test and refine your designs. If your manufacturer is on another continent, the back-and-forth shipping and feedback loops can take months. That delay might kill your speed to market.

With a local CNC machining manufacturer, prototypes can be made quickly, and any necessary tweaks get handled faster. You shorten the design iteration cycle and position yourself ahead of competitors who are still waiting for shipments. This agility is crucial in fast-moving industries.

Access to a Network of Local Suppliers

Many local CNC shops have relationships with other suppliers—such as raw material providers, finishing services, or assembly experts. These connections can help you bundle multiple services under one umbrella, simplifying your supply chain.

You might find a partner who can handle CNC milling, CNC turning, surface finishing, and even packaging, all through their local network. This synergy can reduce overhead and improve communication across different production stages, ultimately boosting product quality and consistency.

Local vs. Overseas CNC Manufacturing

Below is a quick look at how local CNC machining manufacturer compares to overseas options in key areas. The numeric scale is from 1 to 5, with 5 being the most favorable rating and one being the least favorable.

| Factor | Local CNC | Overseas CNC |

|---|---|---|

| Lead Time (1=Long, 5=Short) | 5 | 2 |

| Communication (1=Hard, 5=Easy) | 5 | 2 |

| Shipping Complexity (1=High, 5=Low) | 4 | 2 |

| Quality Control (1=Risky, 5=Reliable) | 5 | 3 |

| Overall Cost Stability (1=Low, 5=High) | 4 | 3 |

This table isn’t a one-size-fits-all guide. Some overseas companies provide fantastic service. However, generally speaking, local CNC machine tools wins in areas like lead time, communication, and cost stability.

Easier Communication in Emergencies

Emergencies happen. Machines break down, orders change, or new design requirements pop up without warning. When you’re working across multiple time zones, every hour of delay can result in mounting stress and potential revenue loss.

Local partners can respond faster. You can schedule emergency meetings, phone calls, or site visits without waiting until midnight. Handling urgent situations in real time is a priceless advantage that keeps your operations steady.

Assurance of Regulatory Compliance

In some industries—like automotive, aerospace, or medical—strict regulations must be followed. Navigating these rules is simpler when you and your manufacturer share the same jurisdiction. You’ll both be on the same page regarding local laws and industry standards.

With an overseas CNC machining manufacturer, you might encounter different or less stringent regulations, leading to surprises. Working locally offers reassurance that both parties understand the relevant certifications, guidelines, and best practices for your sector.

Enhanced Sustainability

Environmental concerns are more important than ever. By picking a local CNC machining manufacturer, you shrink your carbon footprint—shorter shipping routes mean fewer emissions. Plus, local manufacturers are often subject to stricter environmental rules, encouraging them to invest in greener operations.

This choice can boost your brand’s image. Customers and stakeholders appreciate businesses that act responsibly. If sustainability is a core value for your company, working with a local shop aligns well with your mission and marketing messages.

Better Cultural Alignment

Cultural nuances play a big role in business relationships. You might have different holidays, work ethics, or communication styles if your partner is halfway around the world. That’s not always a deal-breaker, but it can create friction and confusion.

Local manufacturers often share similar customs, work hours, and holiday schedules. This alignment simplifies project planning, avoiding downtime caused by unexpected closures or cultural misunderstandings. It makes your collaboration smoother and more pleasant overall.

Greater Trust and Accountability

Working side by side with a local manufacturer fosters a sense of accountability. Your partner knows you can visit anytime, so they have an added incentive to meet your requirements on time and within spec.

You also gain a more trustworthy relationship. It’s reassuring to know that if something goes wrong, you can resolve it face-to-face. This real-world accountability often leads to fewer quality issues and a more respectful business partnership.

Potential for Collaborative Innovation

Local manufacturers may be more receptive to brainstorming sessions and creative collaborations. You can pop in for a quick chat about a new product design or ask for suggestions on manufacturing methods. That’s tougher to do with a partner overseas.

When your CNC machining manufacturer contributes ideas, you might discover more efficient production techniques, cost-saving measures, or design improvements. These joint innovations can set you apart in a crowded marketplace and give you a competitive edge.

Easy Scaling for Future Growth

As your business grows, you might need more services, faster turnaround, or advanced machine capabilities. A local CNC shop can upgrade its equipment or expand staff more swiftly to keep up with your rising demands—especially if you have a proven track record together.

Scaling up with an overseas partner often involves shipping route adjustments, new customs procedures, or changing financial regulations. This can slow you down at a critical growth stage. A local CNC machining manufacturer simplifies expansion, ensuring your success isn’t hindered by distance.

Fact: According to a recent study on U.S. manufacturing trends, businesses that engage local suppliers can reduce overall supply chain costs by up to 15%. They also reported higher on-time delivery rates and stronger customer satisfaction scores.

Conclusion

Choosing a local CNC machining manufacturer comes with numerous advantages that can significantly uplift your business. You get improved quality control, shorter lead times, transparent costs, and strong personal relationships. You can inspect your parts in person, collaborate on design improvements, and adapt quickly to emergencies or market changes.

In short, picking a local CNC partner can help you streamline your production process while supporting your community. You’ll likely end up with better products, happier customers, and a reputation for reliability—all of which fuel long-term success.

FAQ

Why are local CNC machining manufacturer services often more reliable than overseas options?

Local CNC shops benefit from proximity and shared language, allowing for immediate feedback and quick problem-solving. They’re also subject to local regulations, which can improve consistency and quality control.

Is it always more expensive to choose a local CNC manufacturer?

Not necessarily. While labor costs might be higher locally, you save on shipping, customs fees, and the headaches of managing long-distance relationships. The final cost can be equal—or even cheaper—when you factor in all these elements.

How do I confirm the quality of a local CNC machining facility?

Visit them in person if you can. Ask for a tour, look at their certifications, check out sample parts, and talk to their team. Request references or testimonials from previous clients to get real-world feedback.