CNC machining has transformed how makers and manufacturers create parts, bringing together precision, automation, and versatility. But for beginners, learning CNC can feel intimidating. This guide will demystify the process, covering basic CNC machine operations, programming fundamentals, and tips for starting strong.

Whether you want to build prototypes, launch a side business, or simply explore a fascinating hobby, this resource will set you up for success — especially if you’re considering professional CNC Machining Services in the future.

Table of Contents

Why Learn CNC Machining? Key Benefits for Hobbyists and Professionals

Precision and Repeatability

Unlike manual machining, CNC systems follow programmed instructions to make cuts exactly the same way every time. This repeatability is essential if you want to produce multiple identical parts or maintain high quality.

Time Savings

Once you’ve created your program and set up your material, the machine does the work with minimal supervision. Jobs that could take hours by hand can be finished in a fraction of the time.

Customization Potential

You can produce custom components on demand, whether it’s a one-off prototype or small production runs. From personalized gifts to functional machine parts, CNC machining is ideal for unique projects.

Career and Business Opportunities

CNC skills are valuable in fields like aerospace, automotive, woodworking, jewelry, and more. Even small-scale workshops and hobbyists can turn CNC machining into a side income by offering engraving, cutting, or part-making services.

Types of CNC Machines and What They Do

Not all CNC machines are the same. Each type specializes in certain tasks and materials. Here’s a deeper look:

- CNC Mills

- Use rotating cutting tools to remove material.

- Often used for shaping metal and plastic into complex 3D forms.

- Great for prototypes, molds, and precision parts.

- For more complex geometries and tight tolerances, 5-Axis CNC Machining enables efficient multi-surface cutting that’s ideal for aerospace, automotive, and medical components.

- Use rotating cutting tools to remove material.

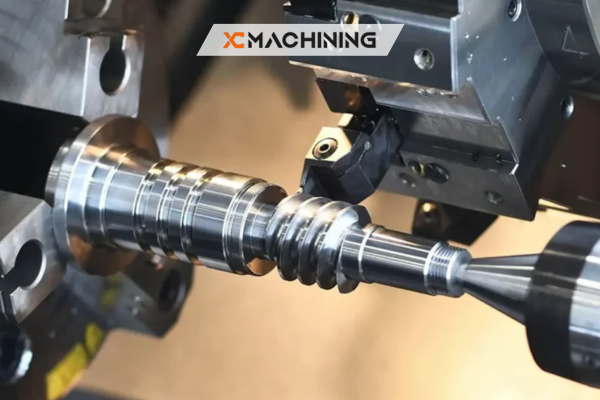

- CNC Lathes

- Rotate the workpiece while cutting tools remove material.

- Ideal for making symmetrical objects like bushings, shafts, and rings.

- A good choice if your projects involve round parts.

- Rotate the workpiece while cutting tools remove material.

- CNC Routers

- Move cutting heads over flat sheets of material.

- Commonly used for woodworking, sign-making, and plastics.

- Typically more affordable and beginner-friendly.

- Move cutting heads over flat sheets of material.

- CNC Plasma Cutters

- Use an electrical arc and compressed gas to slice through metal sheets.

- Faster than mechanical cutting but requires safety precautions.

- Use an electrical arc and compressed gas to slice through metal sheets.

- 3D Printers (Bonus Mention)

- Create objects by adding material layer by layer.

- Excellent for prototypes and complex shapes without subtractive cutting.

- Create objects by adding material layer by layer.

Visual Comparison Tip:

If you’re unsure which machine fits your needs, look for side-by-side charts that compare capabilities, materials, and costs.

CNC Machining Essential Tools & Materials for Beginners

To get started safely and effectively, you’ll need:

Cutting Tools

- End mills come in various diameters and shapes for milling.

- Drill bits create holes of different sizes.

- Lathe tools shape rotating workpieces.

- Always match your cutting tool to the material you plan to machine.

Workholding Tools

- Vises and clamps secure your workpiece to the machine bed.

- Fixtures help hold irregular shapes in place.

- Double-sided tape and vacuum tables can be helpful for thin materials.

Safety Equipment

- Eye protection is mandatory to prevent injury from chips and debris.

- Ear protection is recommended if your machine is loud.

- Dust collection systems help keep your workspace clean and safe.

Starter Materials

- Machinable wax is perfect for testing your toolpaths without damaging tools.

- Soft woods like pine or MDF are affordable practice materials.

- Acrylic sheets are great for learning feeds, speeds, and bit selection.

Pro Tip:

Never rush your first cuts. Practice on scrap material until you’re confident with setup and operation.

CNC Machining for Freshers: A Step-By-Step Roadmap

1. Choose Your CNC Machine

- Decide what materials you’ll cut and what size parts you want to make.

- Research machines in your budget and read user reviews.

- Consider shipping, assembly, and setup requirements.

2. Install and Set Up Software

- CAD (Computer-Aided Design) software lets you draw parts.

- CAM (Computer-Aided Manufacturing) software generates toolpaths.

- Some programs combine CAD and CAM in one, like Fusion 360.

3. Learn Basic G-Code Commands

- G-code tells the machine where to move and how fast.

- Start by understanding commands like:

- G0 – Rapid movement.

- G1 – Controlled cutting movement.

- M3 – Spindle on.

- M5 – Spindle off.

- G0 – Rapid movement.

- Practice reading and editing simple G-code scripts.

4. Create Your First Project

- Begin with a simple engraving or a 2D contour cut.

- Focus on setting up your origin (zero point) accurately.

- Once you’re confident, you can scale to functional prototypes or small product batches using technologies like Plastic Injection Molding to refine your ideas before mass production.

5. Inspect and Troubleshoot

- Measure your finished part to see if it matches your design.

- Look for tool chatter, burn marks, or inaccurate cuts.

- Adjust feed rates and depth of cut as needed.

Choosing Your First CNC Machine: 5 Things to Consider

Budget Ranges

- Entry-level desktop routers start around $300–$1,500.

- Mid-range mills and lathes cost $2,000–$5,000.

- Professional machines often exceed $10,000.

Size and Footprint

- Measure your workshop space before buying.

- Account for clearance around the machine for maintenance.

Materials You Want to Cut

- Not every machine can handle metals.

- If you plan to cut aluminum or steel, ensure the frame and spindle are strong enough.

Software Compatibility

- Some machines require proprietary software.

- Confirm you can use your preferred CAD/CAM tools.

Support and Tutorials

- Choose a machine with an active online community.

- Good documentation and support make learning much easier.

Beginner-Friendly CNC Software Options

Fusion 360

- Free for hobbyists and startups.

- Powerful 3D modeling and toolpath generation.

- Large library of tutorials.

Easel

- Cloud-based and very beginner-friendly.

- Great for simple 2D and 2.5D projects.

Carbide Create

- Free software designed for Shapeoko users but works with other machines.

Mach3

- A popular control interface for DIY CNC builds.

VCarve Desktop

- Excellent for sign-making and woodworking.

Tip:

Many companies offer trial versions—test before you commit.

Easy CNC Projects to Build Your Skills

Start with straightforward, low-risk projects:

Name Plaque

- Learn engraving and contouring.

- Estimated Time: 1–2 hours.

Coaster Set

- Practice simple pocketing and finishing.

- Estimated Time: 2–3 hours.

Simple Box with Lid

- Learn multiple operations and tool changes.

- Estimated Time: 4–5 hours.

Custom Keychain

- Great for small gifts.

- Estimated Time: 1 hour.

Creating a few simple items builds confidence and helps you learn how different materials cut. When you’re ready to explore advanced materials and scalable production, solutions like Sheet Metal Fabrication open up new creative and commercial possibilities.

Common Beginner Mistakes (And How to Avoid Them)

Wrong Tool Selection

- Always check the material compatibility chart.

- Using the wrong cutter can break tools or damage your workpiece.

Overlooking Safety

- Never leave the machine unattended while cutting.

- Keep loose clothing and long hair secured

Skipping Calibration

- Forgetting to set zero points results in inaccurate cuts.

Poor Material Choice

- Start with inexpensive materials that are forgiving.

- Avoid exotic woods or metals until you gain experience.

Ignoring Feeds and Speeds

- Incorrect settings can cause burn marks, chatter, or tool wear.

Learning Resources and Communities

YouTube Channels

- NYC CNC – Focused tutorials on machining techniques.

- Winston Moy – Clear videos on workflows and machine reviews.

- Saunders Machine Works – Great for learning Fusion 360.

Online Communities

- CNCZone.com – Forums covering all machine types.

- Reddit r/CNC – Helpful advice and project sharing.

- Facebook Groups – Many hobby CNC groups offer fast feedback.

Online Courses

Tip:

Joining a community speeds up learning and helps you troubleshoot challenges.

Final Tip:

Start small, learn from mistakes, and celebrate your progress. The journey into CNC machining is as rewarding as the projects you create.