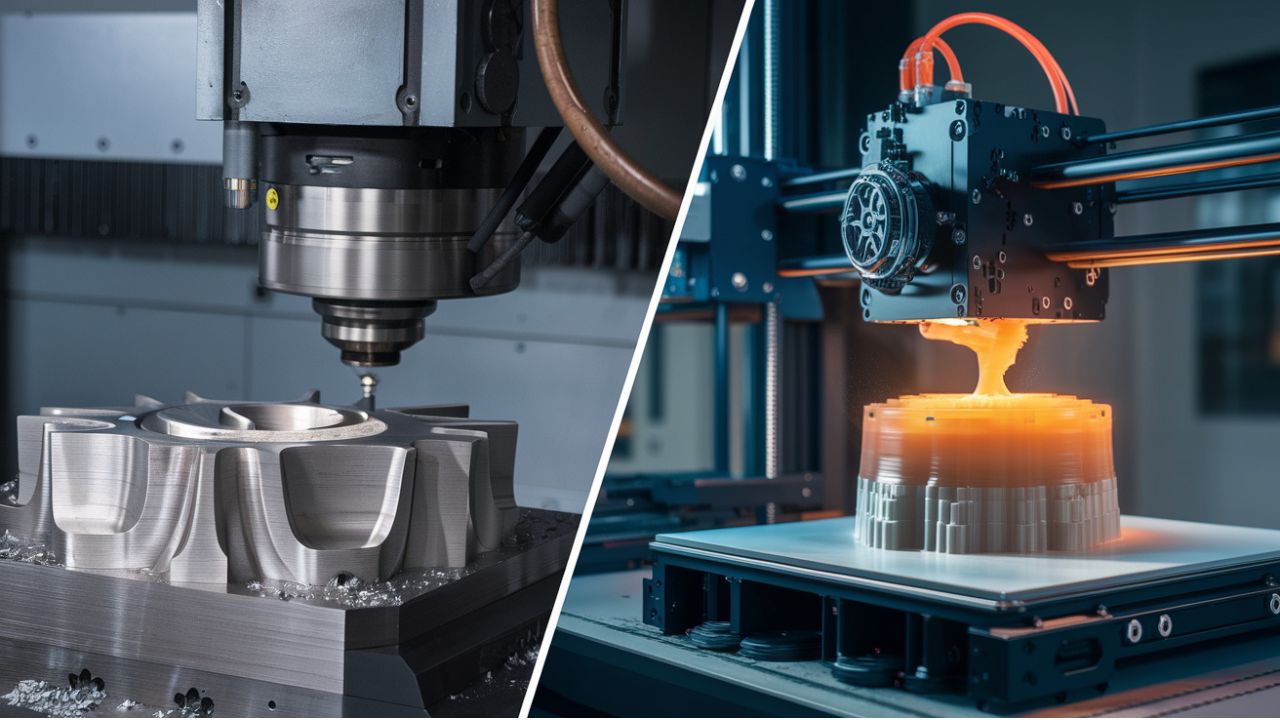

CNC Machining vs 3D Printing technologies offer unique strengths to manufacturers during parts’ fabrication. Even though they are distinct, they can create similar products for vast applications.

This article discusses a detailed review and a distinction between CNC machining and 3D printing. It also includes the advantages of either process and factors to consider when deciding which to choose for your project.

Subtractive and Additive Manufacturing: What is CNC Machining vs 3D Printing?

CNC machining is a subtractive manufacturing process. It involves using computer-controlled machines to cut out pieces of material from a solid block till the desired shape is achieved. Typical CNC machines include various cutting tools – lathes, mills, and drills, which are controlled by computer codes, ensuring the process’s precision. Because of this, CNC machining vs 3D printing is often the choice for applications demanding high accuracy and mechanical strength.

On the other hand, 3D printing is an additive manufacturing process. It involves adding and combining several materials to build the intended structure. During the process, a 3D printer deposits material, often plastic polymers or resins, in a precise pattern, layer by layer, using a digital model till the desired shape is created. This additive process offers more flexibility, allowing manufacturers to develop and customize parts with complex geometries, even beyond CNC machining vs 3D printing capabilities.

These two manufacturing operations present manufacturers’ and machinists’ distinct approaches to suit specific fabrication and prototyping needs. While machining focuses on high precision and tight tolerances fabrication, 3D printing revolutionizes design limitations through additive layering.

Advantages of CNC Machining

The scope of Computer numerical control (CNC) machining involves using computer programs and codes that the machine interprets to create the intended product. This provides the method with unique benefits, making it one of the go-to choices, especially for high-precision projects.

Below is a quick overview of its advantages.

Extreme Precision and Tolerance

Since CNC machining is computer-controlled, it ensures the device creates parts and structures with impeccable precision and tight tolerance. This feature makes the process valuable to aerospace and medical device fabrication industries, where a slight deviation may be detrimental. Machining operations attain high dimensional accuracy even when designing parts with complex geometries and intricate details.

Strength and Durability

Machined parts often possess considerable strength and durability. This advantage makes the machining suitable for components and structures subject to mechanical stress and extreme conditions.

Versatility

CNC in Automotive Industry is highly versatile, with the process able to machine parts made of various materials, including metals, plastics, and composites. The operation is ideal for creating parts with diverse mechanical properties.

Fine Surface Finishing

Machining operations meticulously cut pieces off a workpiece, leaving the edges smooth and delicate. This ensures the creation of parts with appealing aesthetics, reducing the need for post-processing operations.

Various Applications

This subtractive manufacturing process benefits various industries, including automotive, aerospace, medical devices, etc. As mentioned earlier, the process is highly versatile and adaptative, making it the go-to choice for vast manufacturing solutions.

Advantages of 3D Printing

Like CNC machining vs 3D printing also offers manufacturers unique advantages. Below are some of them:

Design Freedom and Flexibility

3D printing allows manufacturers some levels of freedom to explore their creativity. The manufacturing process can replicate almost all kinds of structures, regardless of design complexities. Therefore, it is the go-to method for fabricating sophisticated components that prove challenging for other manufacturing processes.

Rapid Prototyping

3D printing boasts impeccable manufacturing speed, which makes the process valuable for rapid prototyping. It expedites the traditional elongated production cycles, allowing the quick manufacturing of prototypes for testing and other intended uses.

Limited Material Waste

Manufacturing with CNC machining vs 3D printing involves building the part or structures in layers till the intended shape is completed. Therefore, the process utilizes almost the exact amount of material required to create a piece, leaving little to no waste.

Minimal Tooling Constraints

Unlike CNC machining, which has different tooling setups depending on a particular fabrication, there’s no such complex tooling modification in 3D printing. It’s basically the same printer for several fabrications.

Detailed Comparisons Between CNC machining vs 3D printing

This section will compare the differences between CNC Machining vs 3D Printing using their distinct properties and manufacturing capabilities.

Material Selection

CNC Machining vs 3D Printing allow manufacturers to create parts using various materials. The versatility of either process makes them valuable for enormous applications. However, CNC machining materials have a more extensive range, including metals, plastics, composites, and even glass. In contrast, 3D printing is often restricted to plastics, resins, and polymers. However, due to technological advancements, there are special 3D printers for printing metals, but it is expensive.

Tolerance, Precision, and Accuracy

Regarding tolerance, precision, and accuracy, CNC machining vs 3D printing, even though both operations create products with dimensional accuracy requirements. Some manufacturers may first 3D print the part, then apply machining during post-processing to achieve the desired tolerance.

However, when manufacturing parts with strict tolerance specifications, it is better to use CNC machining. While high-end 3D printers can achieve precision of up to ±0.100 mm, CNC machining tolerance may be as low as ±0.005 mm or tighter, especially for metals. Therefore, machining is the better alternative for such high precision.

Operation

Considering the more straightforward manufacturing process, 3D printing is relatively easier to operate. The operational setup includes preparing the file, selecting part orientation, fill, and supports; then, the machine starts to print unassisted.

On the other hand, CNC machines often require skilled machinists with significant knowledge of programming. The operation involves creating distinguished tool paths and machine setups, which include selecting different tools based on operational requirements. Also, the operator must determine the required cutting tool, and rotational speed and sometimes adjust the material during machining.

Design Complexity

Both methods can create parts with complex designs. However, they approach it differently. For example, during machining, the machine carefully cuts out components of the material till the desired shape, bearing all intricate details, is achieved.

Whereas in CNC machining vs 3D printing, the machine carefully prints each structural feature, layer by layer, allowing it to attain near-impossible and even design intricacies that may be challenging for traditional machining. So, 3D printing can create geometries and structures that are impossible to replicate by other conventional manufacturing methods. However, it is limited to choosing a wide of materials compared to CNC machining.

Manufacturing Costs

In general, 3D printing is a cost-effective manufacturing process. However, manufacturing costs depend on the volume of production and the manufacturing speed required to meet a close deadline. With regards to low and high-volume production, CNC Machining is more appropriate, as it can create the necessary parts at astonishing speed and spreads the cost of initial setup cost across each fabrication.

On the other hand, CNC machining vs 3D printing is the better alternative for rapid prototyping. It’s cheaper to 3D prototypes at high speeds because it does not require expensive molds and different tool setups.

However, other factors may affect the cost of either manufacturing process, such as choice of material and ease of manufacturing required parts.

Surface Finishes and Post-Processing

Both manufacturing processes create parts with a good appearance that you may not even require elaborate surface finishing and post-processing needs. However, in this case, CNC Machining edges 3D printing. The machines neatly cut or reduce the size of the workpiece with high precision, leaving the edges of the final product with a high-quality finish and impeccable smoothness for mating with other structures. Achieving such smoothness with 3D printing may require further finishing, like sanding or polishing.

CNC Machining vs. 3D Printing: Which Should You Choose?

Often, different manufacturing processes are suitable for fabricating an intended part. Therefore, the onus lies on the manufacturer to decide the most appropriate method for his fabrication. That said, it is no longer news that CNC Machining vs 3D Printing have vast applications and even create similar parts and structures.

However, depending on factors such as cost-effectiveness and design specifications, either method may benefit the end product better. Below is a brief overview of factors to consider when selecting the better manufacturing for your fabrication between CNC Machining vs 3D Printing.

Cost Considerations

Manufacturing cost is an integral factor that needs consideration. However, it often depends on how many parts you intend to produce. 3D printing is more cost-effective when dealing with prototypes for verification, but CNC is the better alternative for small and large volumes.

Choice of Material

Regarding material options, CNC can work better with more kinds of materials, the more rigid ones like titanium and stainless steel. But if the fabrication is plastic-based or intended to be lightweight, you should use 3D printing. Also, CNC machining is better for fabricating components requiring considerable strength.

Design Complexities

Considering design complexities, either manufacturing process is ideal for complicated structures. However, additive manufacturing can achieve more complex features.

Tolerance and Precision Specifications

CNC is the better choice for parts with strict tolerance and high-precision specifications. In fact, multi-axis CNC machines, like 5-axis machines, will be better suited for achieving such design complexities yet maintaining high dimensional accuracy.

Production Volume and Time Constraints

If the project calls for rapid prototyping, CNC machining vs 3D printing is the best fit. However, CNC machining is the better alternative for bulk manufacturing, especially for a short timeline. Its fast production and processing speeds edge 3D printing, especially for large production.

Generally, deciding which process to use for your fabrication requires careful evaluation of the demands of your project. Therefore, it depends on your manufacturing goal, budget, and timeline, as either operation is reliable, offering vast applications to various manufacturing industries.

Can CNC and 3D Printing Replace Each Other?

No, they shouldn’t replace each other.

Indeed, CNC and 3D printing are two innovative manufacturing technologies, each having an advantage over the other. However, their dynamic extends beyond competition, breaching into a harmonious collaboration that leverages the district strength of either process.

CNC machining affords manufacturers unparalleled precision and material versatility, making the process indispensable, especially for fabricating parts with tight tolerances. Still, it preserves the mechanical integrity of the machined part, regardless of the material type – plastics or metals.

On the other hand, 3D printing introduces manufacturers to new design possibilities. Compared to conventional machining, 3D printing possesses almost zero constraints, allowing the manufacturers and designers to create what they imagine. Still, it’s capable of fabricating these prototypes with impeccable speed.

That said, by integrating these two techniques, manufacturers already manufacture parts and structures. This is often referred to as hybrid manufacturing, where the manufacturer leverages the advantage of either process.

XC Machining: Your Partner for Expert CNC Machining and 3D Printing Services

Indeed, having a detailed knowledge of different manufacturing processes, including CNC Machining vs 3D Printing, makes it easy to decide the best choice for your fabrication. However, partnering with a reputable service is crucial, as having these machines may be impossible because of their insane cost.

XC Machining is just that service you need for your CNC machining and 3D printing services. We offer premium fabrication and prototyping services, even if they come with high-precision and strict tolerance specifications. Our expert will help choose the best manufacturing method and material for your specific projects. Just contact us today and get a free quote!

Conclusion

Though CNC Machining vs 3D Printing follow different paths – subtractive vs additive manufacturing- they still do the job. Indeed, each has distinct qualities that make them crucial to the manufacturing industry, yet they can’t replace each other. Instead, manufacturers are embracing the advantages of either process to create room for fabricating structures with vast applications.

FAQs

What are the benefits of CNC machining over 3D printing?

The benefits of CNC Machining over 3D printing include better accuracy and precision, increased choice of material, and reduced need for surface finishing and post-processing. Also, CNC machining is cheaper for volume production and creates incredibly durable parts.

What are the benefits of 3D printing over CNC machining?

The benefits of 3D printing over CNC Machining include creating parts with more complex geometries, rapid prototyping, and reduced waste. Also, 3D printing allows for better customization without retooling and offers the operator some level of design freedom and a chance to experiment and be more innovative with the design.

Can CNC machining and 3D printing be used together in a project?

Yes, manufacturers can incorporate CNC Machining and 3D printing into a single project. This technique is often termed hybrid manufacturing. It allows the machinist to leverage the strength of either method to create a unique structure.