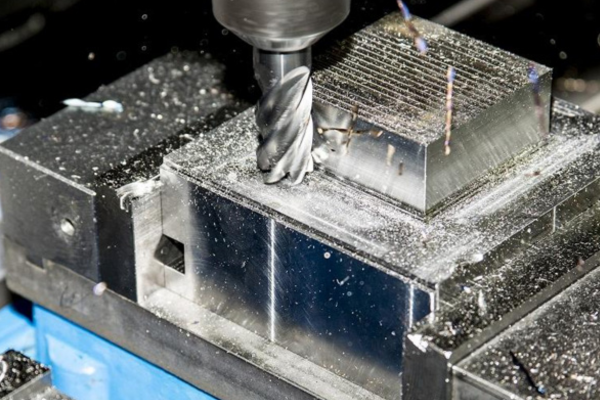

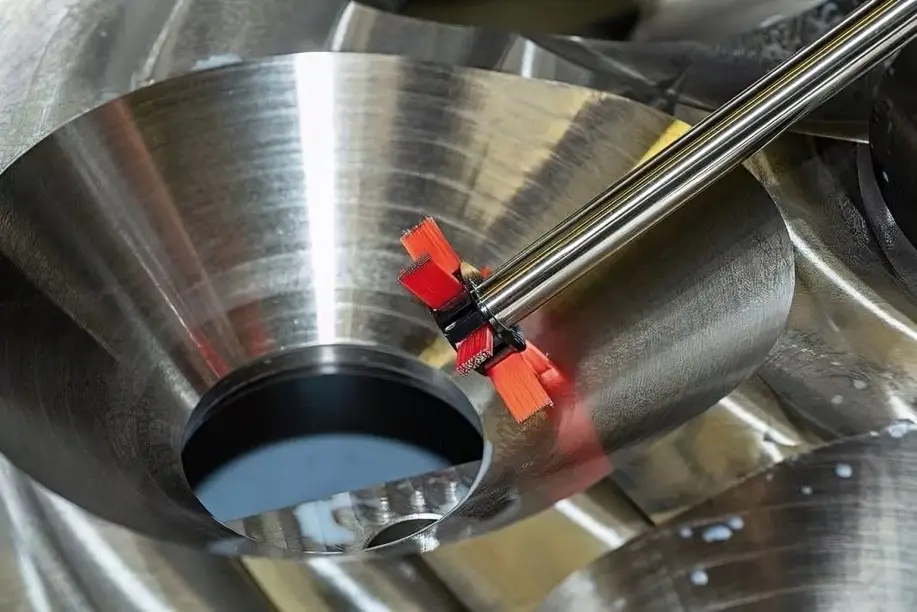

In CNC milling, tool offset refers to the adjustment made to account for the cutting tool’s length and diameter. This ensures that the tool cuts accurately in relation to the workpiece, preventing dimensional errors. By setting precise offsets, machinists define the correct starting point, ensuring that parts are manufactured to exact specifications. Proper tool offsets are crucial for achieving consistent, high-quality results throughout the milling process.