Have you ever thought about creating custom signs, furniture, or intricate designs in wood and metal without spending countless hours on hand-carving? For a lot of hobbyists, small business owners, and even big manufacturers, that’s a real problem. Traditional fabrication methods take time, require lots of skill, and can be tricky to scale up.

The CNC router machine is changing the game by offering a faster, highly accurate way to carve and cut materials. With computerized controls, you can design in software and let the machine do the rest.

In this article, we’ll explore how the CNC router machine is reshaping custom fabrication. We’ll start with its rise in popularity, discuss different ways people use it, and highlight best practices to get top-notch results. Stick around to learn tips, see real-world examples, and discover how you can harness this technology for your own creative or commercial projects.

The Rapid Rise Of CNC Router Machine

In the last few decades, digital manufacturing took off, and so did CNC routers. They once belonged only in large factories with big budgets. But now, a CNC router machine can fit in a home garage. From sign-making to furniture prototypes, these devices fuel creativity and boost productivity everywhere.

Emergence Of Affordable Models

Small workshops gained access when prices dropped. Hobbyists tinkered, producing intricate carvings once thought impossible. Suddenly, guitar makers, sign creators, and DIY furniture builders had precision tools rivaling major factories, allowing them to craft stunning pieces without draining their life savings.

Integration With Software

As CAD/CAM programs became user-friendly, people designed complex shapes with ease every day. Rather than code from scratch, folks drag shapes in design software and then let the machine translate commands into perfect cuts. This synergy accelerated custom fabrication like never before.

Online Community Support

Forums and social media groups popped up, letting newbies ask questions and share settings. Makers swapped project files, bridging the learning gap. The result? A global group of router enthusiasts fueling a continuous stream of fresh ideas and practical tips.

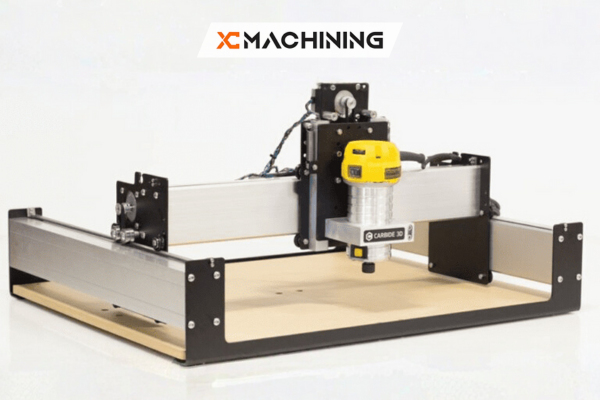

What Is A CNC Router Machine?

A CNC router machine uses computer-controlled movements to cut or carve into wood, plastics, and sometimes metals. Picture a drill bit mounted on a gantry that can move along multiple axes: typically X (left-right), Y (forward-back), and Z (up-down). With these three axes, you can engrave letters or shapes into a board. More advanced machines have 4th or 5th axes for more complex designs.

Compared to manual carving or cutting with a jigsaw, a CNC machines offers pinpoint accuracy. You feed in a digital design—often created in CAD software—and the machine follows that blueprint. Speed, feed rate, and tool path are all precisely controlled. That means consistent cuts every time, perfect for mass-producing parts or ensuring your design always looks the same.

Key Benefits Of CNC Router Machines

So why choose a CNC router machine over other fabrication tools? Let’s break it down:

- Precision: You can trust the machine to cut along your lines.

- Repeatability: Each part is identical, which is ideal for batch production.

- Efficiency: Minimal manual input once you hit “start.”

- Versatility: Works with wood, plastics, foam, and softer metals.

- Complex Designs: Intricate details and 3D contours are within reach.

These advantages make CNC routers a go-to solution for sign makers, cabinet builders, and creative hobbyists.

Common Materials For CNC Router Projects

Below is a simple table that showcases popular materials you can process on a CNC router machine, along with some quick notes on each.

| Material | Ease Of Cutting | Typical Projects | Notes |

|---|---|---|---|

| Wood (Hardwood) | Easy to Moderate | Furniture, signs, decorative panels | Hardwoods need slower passes to avoid burning |

| Plywood | Easy | Cabinets, structural pieces, crates | Use sharp bits to avoid chip-out |

| MDF | Easy | Door panels, speaker boxes, molded shapes | Dusty: good dust collection is important |

| Acrylic/Plexi | Moderate | Sign lettering, illuminated shapes, displays | Adjust speed/feeds to prevent melting |

| Soft Metals | Hard | Aluminum nameplates, light metal components | Needs slower speeds and lubrication |

| Foam | Very Easy | Prototyping, packaging, decorative shapes | Very fast cuts; watch out for dust buildup |

(Note: “Ease Of Cutting” depends on machine power, bit type, and operator experience.)

Step-By-Step: How A CNC Router Machine Works

Step One: Design Your Part

You begin with a digital model or sketch in CAD software (like Fusion 360 or SketchUp). This is where you decide on shape, size, and fine details.

Step Two: Generate Toolpaths

Next, you import that design into a CAM (Computer-Aided Manufacturing) program. You pick bit sizes, specify speeds, and define how deep each cut goes. The software then creates code (often G-code) telling the router what to do.

Step Three: Secure The Material

You fix your board or sheet onto the router’s work bed. Clamps or vacuum tables hold it firm. This is essential for safety and accuracy.

Step Four: Start The Cutting Process

Press go, and the CNC router machine follows the programmed toolpaths, carving or cutting away. You watch for any issues, like a bit becoming loose or unexpected chatter.

Step Five: Final Cleanup

After the cutting finishes, you remove the piece and might sand the edges, do a quick surface finish, or assemble it if multiple parts are involved.

Popular Uses In Custom Fabrication

CNC router machines thrive in countless scenarios. Let’s explore a few:

- Sign Making: You can engrave letters and logos with perfect consistency, adding flair with 3D effects.

- Cabinetry And Furniture: Carve ornate trim or precise joinery that fits together smoothly.

- Stage And Props: Theater crews sculpt large foam pieces for sets, saving time over manual sculpting.

- Architectural Panels: Create decorative room dividers or wall accents with repeated patterns.

- Hobby And Craft Projects: Model planes, puzzle pieces, personal décor—endless possibilities.

Thanks to modern software and hardware, even small shops or DIY enthusiasts can produce top-tier results.

Getting Started With A CNC Router

Machine Selection

Look for:

- Adequate bed size to hold your typical material sheets cutting.

- A sturdy frame to handle vibrations.

- A powerful spindle motor if you plan to cut hardwood or metals.

Bits And Tooling

Router bits come in various shapes—end mills, ball noses, V-bits, etc. The correct choice depends on the cut style you need:

- Straight bits for basic pockets.

- V-bits for decorative lettering.

- Ball nose for smooth 3D contours.

Software Considerations

Programs like VCarve, Aspire, or Fusion 360 can handle both design and toolpath generation. Many come with extensive libraries of bit settings, helping new users avoid guesswork.

Safety Measures

- Wear Eye Protection: Chips can fly off quickly.

- Dust Collection: Wood dust can harm your lungs.

- Ear Protection: High RPM spindles can be loud.

- Proper Tool Inspection: Check bits for damage or dullness.

Advanced Techniques And Trends

CNC router machine technology keeps pushing boundaries. Here are some cool developments:

- 4-Axis And 5-Axis Systems: Capable of rotating or tilting the workpiece or tool, letting you carve complex curves.

- Mixed Media Creations: Combine laser engraving or 3D printing steps for unique designs.

- Robotics: Some shops pair industrial robot arms with CNC router heads for massive-scale sculptures.

- Multi-Tool Carousels: The machine swaps bits automatically, doing rough cuts and then fine details—no manual tool change is needed.

- Smart Sensors: Real-time monitoring ensures consistent cutting depth and adjusts speeds on the fly.

Did you know? Some advanced CNC routers automatically measure tool length before each job, compensating for subtle changes as bits wear down. This keeps every pass consistent without user intervention.

Common CNC Router Bits And Their Uses

| Bit Type | Typical Shape | Best For | Tips |

|---|---|---|---|

| Straight Bit | Straight Flutes | General cutting, pockets, simple edges | Keep RPM moderate to prevent burning |

| Up-Cut Spiral | Helical Flutes (upward) | Efficient chip removal, slots | Watch out for material tear-out on top |

| Down-Cut Spiral | Helical Flutes (downward) | Clean top edges, sign faces | Great for plywood to minimize splinters |

| V-Bit | V-shaped tip | Engraving text, decorative lines | Perfect for sign-making or inlays |

| Ball Nose | Rounded tip | 3D contouring, smooth curves | Use smaller stepovers for a finer finish |

| Compression | Mixed up/down flutes | Sheet cutting with clean top & bottom | Ideal for furniture panels, less sanding |

Conclusion

Today’s world of custom fabrication is thriving, and the CNC router machine stands at its center. From detailed wooden sculptures to functional prototypes, these CNC machine tools give individuals and businesses the power to transform digital designs into tangible goods. If you’re seeking a tool that balances speed, accuracy, and creative freedom, a CNC router machine could be the perfect addition to your workshop.

Ready to bring big ideas to life? By focusing on the right equipment, software, and safety steps, you’ll see just how simple and rewarding routing can be. Whether you’re a hobbyist or a seasoned fabricator, the future looks bright—and your next masterpiece might be just a few lines of code away.

FAQs

Can a CNC router machine cut metal?

Yes, though typically softer metals like aluminum or brass. Harder metals require a rigid machine frame, slower speeds, and possibly coolant.

How long does it take to learn CNC routing?

Basic projects can be learned in a week or two if you’re comfortable with computers. For more complex designs, give yourself a month or more of practice.

Is a dust collection system really necessary?

Absolutely. Wood dust can be harmful to your lungs, and keeping your workspace clean helps the machine run smoothly.

Can I use free software to design projects for a CNC router machine?

Yes, programs like FreeCAD, Inkscape (with plugins), or Fusion 360 (free for hobbyists) are great starts. They handle design and can generate toolpaths.

Do I need a different router bit for every material?

While not always, certain bits work better on certain materials. For instance, plastics often need an O-flute bit to reduce melting. Always consult bit recommendations.