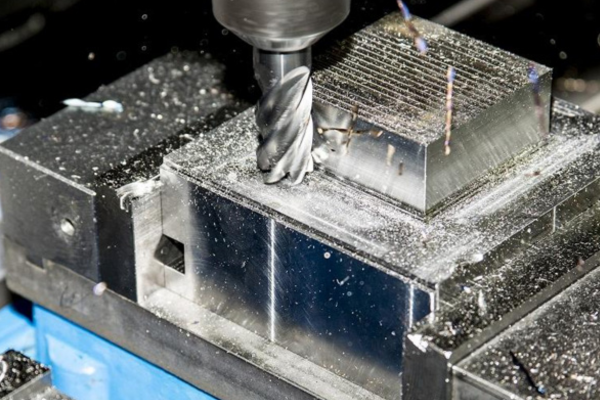

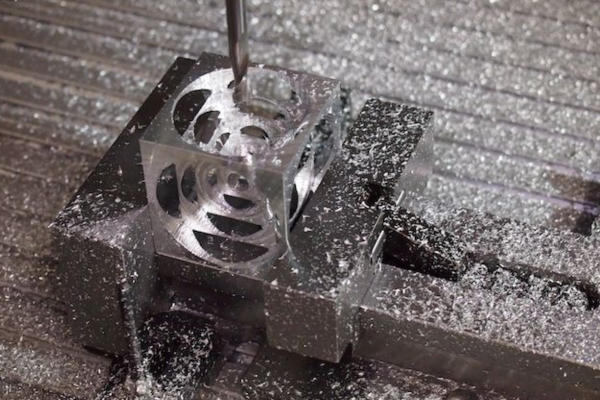

At XC Machining, we specialize in CNC routing services, a precision-driven process designed for cutting and shaping various materials such as wood, plastic, and metal. Using advanced computer-controlled routers, we deliver detailed, consistent cuts and contours for projects that require both complexity and accuracy. Our CNC routing solutions are ideal for industries like automotive, aerospace, and industrial machinery, where precision, repeatability, and efficiency are critical. We ensure high-quality results in minimal time, driving success in every project.

Our CNC routing services are ideal for a variety of applications, including:

- Prototyping: Whether you’re developing a prototype or testing a design, CNC routing provides the precision and speed required for rapid prototyping.

- Custom Parts: CNC routing is perfect for producing custom, one-of-a-kind parts that require precise dimensions and complex shapes.

- Engraving: From logos to product markings, our CNC routers can perform engraving with high-definition results.

- Panel Cutting: Our CNC routers can cut large panels for various uses in construction, interior design, signage, and more.

- Signage: Whether it’s for business signage or decorative pieces, CNC routing allows for intricate and detailed signs that stand out.

Why Choose XC Machining’s CNC Routing Services?

Unmatched Precision and Accuracy

CNC routers operate based on detailed computer programming, significantly reducing human error. This ensures that each cut and shape is executed flawlessly. Such precision is essential for industries like aerospace and automotive, where even the slightest deviation can cause major complications.

Consistent Quality and Repeatability

One of the standout features of custom CNC routing is its ability to produce identical parts consistently. Once a design is programmed, the machine can replicate it with minimal variations, making it indispensable for mass production and prototyping. This consistency ensures that every component meets exact specifications.

Increased Productivity

CNC routers can operate 24/7 with minimal human oversight, allowing for higher production volumes in less time. This capability reduces lead times and increases overall output, while the machine’s ability to handle complex designs further boosts productivity.

Material Versatility

Our CNC routers can work with a broad range of materials, from wood and plastics to composites and light metals like aluminum. This versatility eliminates the need for multiple machines, providing a one-stop solution for various industries.

Cost-Effectiveness

While the initial investment in CNC routing technology may be higher than traditional methods, the long-term cost savings are substantial. Reduced labor costs arise from the ability of one operator to manage multiple machines, while optimized material usage minimizes waste, lowering production costs.

Complex Shape Creation

CNC routing enables the creation of intricate and complex shapes and designs that would be challenging or time-consuming to achieve manually. The multi-axis movement of the machine makes it perfect for executing advanced cuts and patterns, opening new possibilities for creative applications.

Ease of Operation

Operating a CNC router is straightforward once trained. The intuitive software used for programming makes it accessible to technicians without extensive machining experience, ensuring faster onboarding and reducing training times.

Enhanced Safety Features

Modern CNC routers come with advanced safety features, including protective enclosures and dust extraction systems. These features help minimize risks and maintain a clean, safe working environment for operators.

Reduced Labor Requirement

With automation in place, CNC routers significantly decrease the need for manual labor. Tasks typically requiring multiple technicians can now be efficiently performed by fewer operators, resulting in reduced labor costs.

Engraving and Personalization Options

Our CNC routers can also perform intricate engraving tasks, adding personalized designs or text onto materials. This feature is perfect for creating custom items like awards, signage, or custom artwork, adding value through personalization.

Improved Waste Management

The accuracy of CNC routing reduces material waste compared to traditional methods. By optimizing tool paths and minimizing errors, we help conserve resources and reduce the environmental impact of your production process.

Adaptability Across Industries:

From woodworking and furniture making to automotive parts manufacturing, signage creation, and aerospace components, CNC routing services find applications across a wide array of industries. This adaptability makes CNC routers a valuable asset in any manufacturing environment.

Find trusted CNC routing services near me for precise cutting, custom shapes, and clean finishes on wood, plastic, and composite materials with fast turnaround.

Industries We Serve

XC Machining’s CNC Routing services are trusted by businesses across a wide range of industries, including:

- Aerospace

- Automotive

- Consumer Goods

- Electronics

- Medical Devices

- Furniture and Interior Design

- Signage and Advertising

Get a Quote Today

At XC Machining, we believe in transparency and offering competitive pricing without compromising on quality. Get in touch with us today to discuss your CNC Machining project, and we’ll provide you with a personalized quote that fits your budget and timeline.

Contact XC Machining today and let us bring your design to life with precision and efficiency. Whether it’s one part or a production run, our CNC routing services are here to meet your needs!