At XC Machining, precision and efficiency define everything we do. Our advanced injection mold tooling services are transforming manufacturing by delivering high-quality, reliable, and cost-effective components across various industries. Whether you’re designing intricate automotive parts or innovative electronic components, our expertise ensures that your manufacturing processes are seamless and your products stand out.

The Power of Injection Mold Tooling

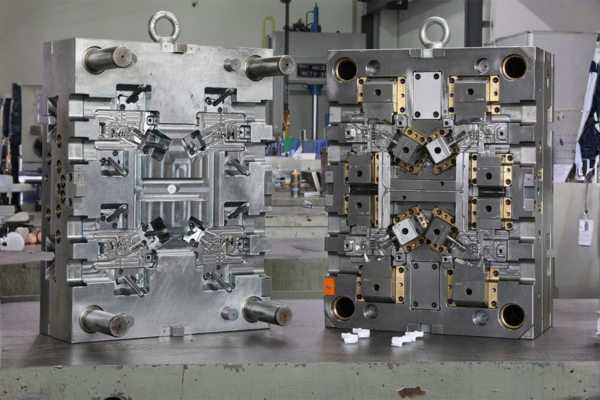

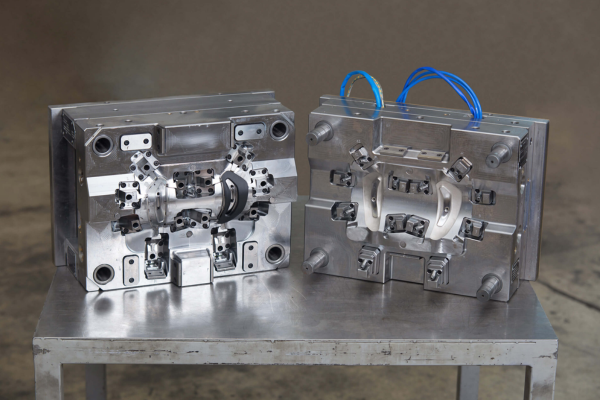

Injection mold tooling is a cornerstone of modern manufacturing. It’s not just about producing parts—it’s about creating components that meet the highest standards of precision, functionality, and design. Let’s dive deeper into why this process is a game-changer for businesses:

Precision & Consistency

When it comes to manufacturing, there’s no room for error. That’s why we prioritize exact tolerances and unparalleled consistency.

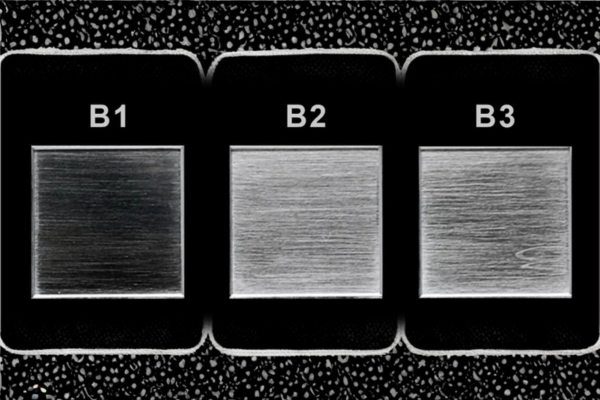

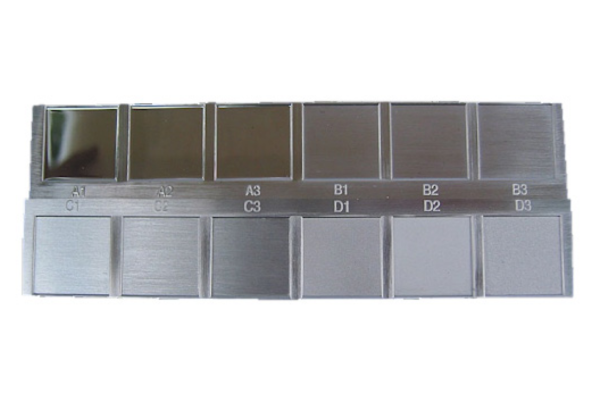

- Exact Tolerances: We ensure dimensions with tolerances as tight as +/-0.001″, so your components always meet precise specifications. This is especially critical for industries like automotive, electronics, and medical devices, where precision can make or break product performance.

- Reliable Quality: With perfected molds, we can produce identical parts in high volumes. This consistency reduces the risk of defects and enhances overall quality, helping you maintain your reputation for excellence.

Design Flexibility

Modern products demand innovative solutions, and injection mold tooling provides unmatched design flexibility.

- Complex Geometries: Create intricate, detailed designs that are difficult—or even impossible—to achieve with other manufacturing methods. Whether you’re designing precision gears, electrical connectors, or custom housings, we can bring your ideas to life.

- Customization Options: Need to adapt quickly to market trends? Injection molding can be modified to produce different variations of a part without significant costs. This adaptability ensures your products stay competitive and relevant.

Material Versatility

Every product has unique requirements, and selecting the right material is crucial to meeting them.

- Wide Material Selection: Choose from a broad range of thermoplastics and thermosets, each offering distinct properties like strength, flexibility, heat resistance, and electrical insulation.

- Hybrid Material Capabilities: Combine multiple materials in a single mold to achieve parts with unique characteristics, enhancing functionality and performance.

Cost-Effective Manufacturing

Injection mold tooling is not only efficient but also highly economical, especially for large-scale production.

- High-Volume Efficiency: The ability to mass-produce parts at high speed reduces the cost per unit, making it a cost-effective solution for businesses of all sizes.

- Operational Savings: With automated processes, labor costs are minimized, and material waste is significantly reduced. This efficiency leads to lower overall production costs, allowing you to allocate resources elsewhere.

Sustainability

We understand the importance of sustainability in modern manufacturing, and injection mold tooling is designed with this in mind.

- Minimized Waste: Precision injection molding ensures that material usage is optimized, reducing waste during production. We also support the use of recycled plastics to promote eco-friendly practices.

- Energy Efficiency: Advanced injection molding machines consume less energy, lowering both operational costs and environmental impact.

Industries We Serve

Our injection molding services cater to a wide range of industries, delivering solutions that meet diverse and challenging requirements:

- Automotive Industry: Producing components that meet the rigorous demands of safety and performance.

- Energy Sector: Crafting precision parts that support efficient energy solutions.

- Industrial Machinery: Ensuring reliability and durability with high-quality components.

- Electronics and Communications: Creating essential parts for advanced electronic devices and communication systems.

More Than Just Injection Molding

At XC Machining, we offer a comprehensive suite of manufacturing solutions to meet all your production needs:

- Vacuum Casting: Ideal for creating detailed prototypes and small production batches, ensuring accuracy and quality at every step.

- Sheet Metal Fabrication: Providing durable, precise metal components for a variety of applications, from machinery to consumer products.

This broad range of capabilities ensures that your manufacturing processes are streamlined, efficient, and perfectly tailored to your goals.

Let’s Build the Future Together!

Are you ready to take your manufacturing to the next level? At XC Machining, we’re here to help you bring your vision to life. Contact us today to discuss your project and get a personalized quote and let’s turn your ideas into reality!