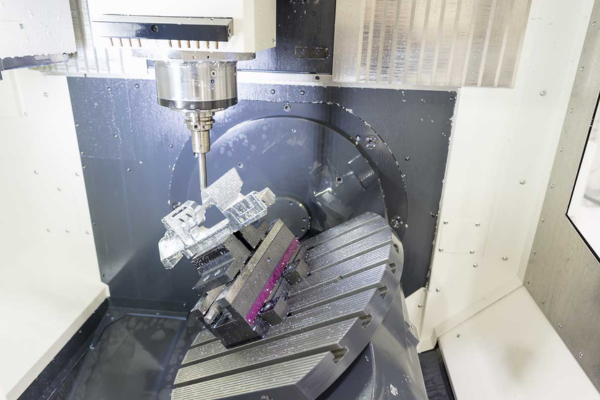

5-axis CNC machining is transforming the manufacturing landscape, allowing for the rapid production of intricate and geometrically complex parts. At XC Machining, our 5 axis CNC machining services are designed to meet the highest quality standards, delivering intricate components with exceptional accuracy, speed, and flexibility. Our extensive capabilities and world-class equipment enable us to provide reliable and efficient solutions for industries ranging from automotive to industrial machinery—all under one roof.

Our 5-Axis CNC Machining Services

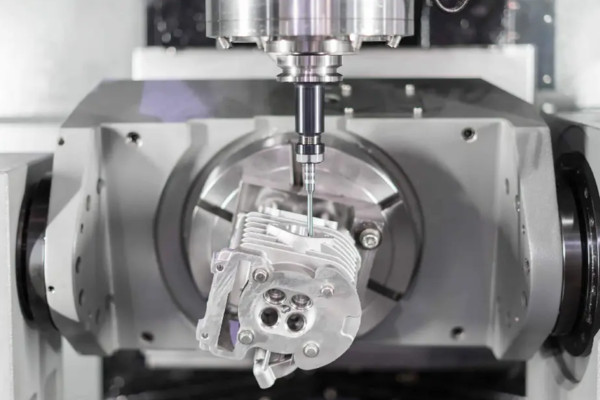

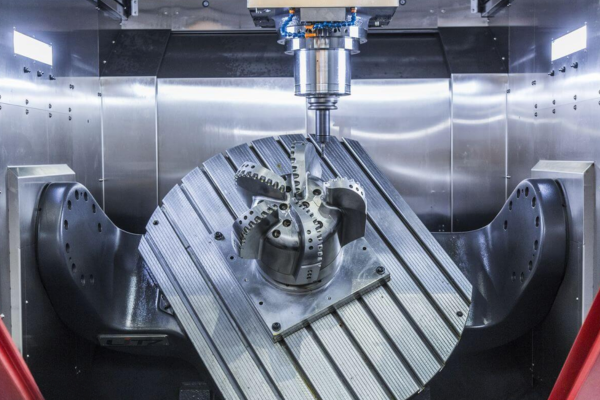

- Complex Geometry Handling: Our 5-axis machines can produce parts with intricate designs that would be challenging or impossible with traditional 3-axis machines.

- Enhanced Precision: The ability to approach the workpiece from multiple angles ensures superior accuracy and tight tolerances.

- Reduced Lead Times: By minimizing the need for multiple setups, we expedite the manufacturing process, delivering your parts faster.

- Cost Efficiency: Fewer setups and increased automation lead to lower labor costs and reduced potential for errors, providing cost savings for our clients.

Industries We Serve

Our 5-axis CNC machining services cater to a diverse range of industries, including:

- Aerospace: Manufacturing complex components such as turbine blades and structural parts with high precision.

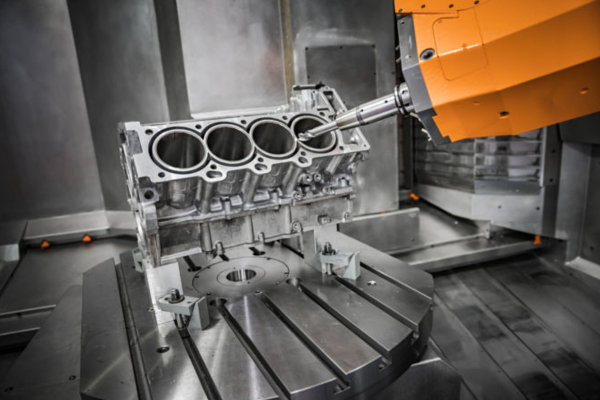

- Automotive: Producing intricate engine components, transmission parts, and custom prototypes.

- Medical: Creating precise surgical instruments, implants, and medical device components.

- Electronics: Fabricating enclosures, connectors, and intricate parts for consumer electronics.

Our Commitment to Quality

At XC Machining, quality is at the forefront of everything we do. Our state-of-the-art 5 axis CNC machines are operated by a team of experienced professionals dedicated to delivering products that meet or exceed your expectations. We adhere to strict quality control processes to ensure each part is manufactured to the highest standards.

Get in Touch

Partner with XC Machining for your next project and experience the benefits of advanced 5-axis CNC machining. Contact us today to discuss your requirements and receive a competitive quote.

Why Choose XC Machining?

- State-of-the-Art Equipment: We utilize the latest 5-axis CNC machines to ensure precision and efficiency.

- Expert Team: Our skilled machinists have extensive experience in handling complex machining projects across various industries.

- Customer-Centric Approach: We work closely with our clients to understand their specific needs and deliver tailored solutions.

- Timely Delivery: Our streamlined processes and commitment to deadlines ensure your projects are completed on time.

Choose XC Machining for unparalleled 5-axis CNC machining services that drive innovation and quality in your products.

Contact us to help you bring your most challenging projects to life with the precision and expertise that only our 5 axis CNC services can deliver.