(CAD) has changed how we design and create products. It’s not just about making designs look good. It’s about precision, efficiency, and creativity. From architecture to automotive engineering, computer aided design is now at the heart of most modern design processes. With computer-aided design, designers, engineers, and architects can take their ideas and bring them to life in ways that were never possible before. In this blog, we’ll explore how computer-aided design is shaping the future of engineering and design.

What is Computer-Aided Design (CAD)?

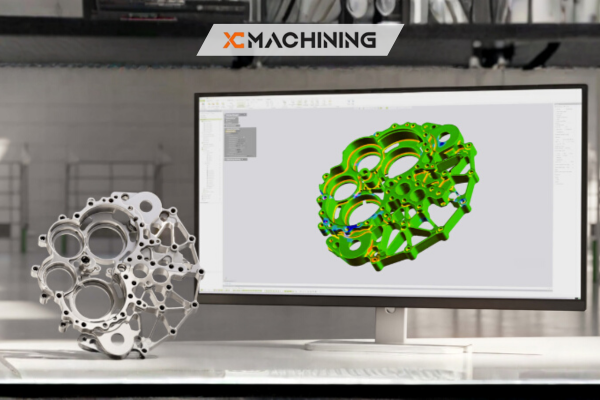

The term computer aided design (CAD) refers to the use of software to design and create models. CAD helps engineers and designers build complex products quickly and accurately. It allows users to produce precise drawings and simulations for everything from buildings to mechanical parts. Without CAD, creating the designs we rely on every day would be much more difficult and time-consuming.

CAD is used to create digital versions of products, making it easier to visualize and modify them. Whether it’s a new car, a skyscraper, or even a small gadget, computer-aided design allows designers to see exactly how it will look and work. It’s a game-changer for design teams around the world.

The Evolution of CAD: From Manual Drafting to Digital Modeling

In the past, engineers and designers would spend hours drawing by hand. They used rulers, pencils, and paper to create designs. However, this method had limitations. Mistakes were costly, and changes often meant starting over. As technology improved, the need for a better solution grew.

In the 1960s, computer aided design was introduced. It started as a basic tool for technical drawings, but over time, it became much more powerful. By the 1980s, CAD software was advanced enough to handle 3D printing. Today, CAD allows designers to create detailed, accurate, and complex designs in a fraction of the time it once took.

CAD has evolved from simple drawings to powerful, interactive models that simulate real-world behavior. This progress has revolutionized how engineers and designers approach their work.

Key Benefits of Using CAD in Engineering and Design

Using computer aided design brings several key advantages. First, it saves time. Designers no longer need to spend hours making physical models or redrawing designs when changes are needed. Instead, they can quickly modify the digital model.

CAD also improves accuracy. Unlike manual drawing, which can have human errors, CAD ensures precision grinding. Designers can work with exact measurements, reducing mistakes and ensuring that parts fit together perfectly.

Finally, CAD enhances collaboration. Multiple team members can work on the same project from different locations, thanks to cloud-based CAD tools. This improves workflow and decision-making, allowing projects to move forward faster.

- Saves time

- Improves accuracy

- Enhances collaboration

These benefits make CAD a must-have tool for modern engineers and designers.

How CAD Improves Precision and Accuracy in Designs

Precision and accuracy are critical in design, and computer aided design makes it easier than ever to achieve both. In CAD, every dimension is set with exact measurements. This means parts fit together as they should, and the product works as planned. With traditional methods, small errors could lead to costly rework. But with CAD, even the smallest changes are easy to make.

Another way CAD improves precision is through simulations. Designers can use CAD to test how a part or product will perform. For example, CAD software can simulate how a car engine will work under different conditions. CAD saves time by catching problems early, reducing the chance of errors after the design is made. Furthermore, its precision machining ensures that designers build products right the first time, leading to fewer delays and lower costs.

Enhancing Creativity with CAD: Breaking Traditional Boundaries

Before CAD, creativity was limited by physical constraints. For example, if a designer wanted to build a complex, intricate shape, they would have to work with paper or clay. But computer aided design allows them to explore new shapes and ideas without limitations.

With CAD, designers can create and test more creative ideas without worrying about the practical difficulties of making them. For instance, a designer can create a unique building with curved walls and intricate patterns, something that would be hard to achieve manually.

CAD opens new doors for creativity, enabling designers to think outside the box and push boundaries that were once considered too difficult.

- No physical constraints

- More creative freedom

- Quick iterations

This freedom allows for more bold and innovative designs that would not have been possible with traditional methods.

CAD and Collaboration: Working Together in the Digital Space

One of the greatest advantages of computer aided design is its ability to facilitate collaboration. In the past, team members often worked separately, using paper blueprints that were hard to share. Now, with cloud-based CAD software, multiple people can work on the same design at the same time.

Whether it’s a small design team or a global group of engineers, CAD enables real-time collaboration. Team members can leave comments, suggest changes, and even create 3D printer parts to share their ideas. This speeds up the design process and ensures everyone is on the same page.

- Real-time collaboration

- Cloud-based tools

- Improved communication

With computer aided design, the design process is smoother and faster, with fewer mistakes and misunderstandings.

The Role of CAD in Prototyping and Product Development

Prototyping is a crucial step in product development, and CAD plays a major role here. In the past, designers had to make prototypes by hand, which took a long time. With computer aided design, designers use digital models to create prototypes quickly and accurately.

CAD enables rapid prototyping, allowing designers to test and adjust changes almost instantly. For example, 3D printing can turn CAD designs into physical prototypes in hours, helping designers test their ideas before committing to expensive manufacturing processes.

This ability to test and tweak designs before production saves both time and money.

The Role of CAD in Consumer Electronics and Product Innovation

In the world of consumer electronics, computer aided design is a key player. Every new smartphone, tablet, or wearable device starts with a CAD model. And these digital designs allow engineers to create the compact, intricate designs that make up modern gadgets.

Designers use CAD to test the functionality and durability of their products before manufacturing them. Moreover, CAD ensures that parts fit together seamlessly, improving both the product’s look and functionality.

- Testing before production

- Efficient design for compact products

- Improved product durability

Without CAD, designers would find it much more challenging to create the sleek, functional electronics we rely on today. And, computer aided design continues to drive innovation in the consumer electronics industry.

The Role of CAD in Aerospace Engineering

In aerospace engineering, the precision of design is crucial. Therefore, CAD software helps aerospace engineers design everything from the smallest components of an aircraft to the most complex systems. These digital models ensure that parts fit together perfectly and function properly in flight.

- Designing complex systems

- Precise testing

- Efficient modifications

Without CAD, designing and testing aircraft would be a much slower and more expensive process.

CAD in the Automotive Industry: Speeding Up Design and Testing

The automotive industry has embraced computer aided design (CAD) for years. CAD has transformed how car manufacturers design vehicles, from the smallest components to the entire car. With CAD, engineers can create complex car parts, test their performance, and even predict how they’ll behave in a crash—all before creating the first prototype.

Without CAD, this level of precision and testing would be almost impossible to achieve before physical manufacturing begins.

- Faster design and iteration

- Crash testing simulations

- Optimized performance

CAD has enabled automotive engineers to design safer, more efficient cars while reducing production costs.

How CAD Software Supports Various Engineering Disciplines

CAD is not just for architects or mechanical engineers. Many disciplines, including civil, electrical, and aerospace engineering, use it. Each field uses computer aided design differently, but the core benefits remain the same: speed, precision, and collaboration.

- Mechanical Engineering: CAD helps create parts, assemblies, and models that fit together precisely.

- Civil Engineering: CAD is used to design infrastructure like roads, bridges, and buildings.

- Electrical Engineering: CAD is key for designing circuits and layouts in electrical systems.

CAD makes it easier to design and visualize complex systems, making it a valuable tool in any engineering field.

The Impact of CAD on Sustainability and Eco-Friendly Design

In today’s world, sustainability is a top priority. Computer Aided Design (CAD) plays a role in reducing waste and improving sustainability. With Computer Aided Design, designers can test materials, simulate energy usage, and optimize designs for environmental efficiency.

For example, engineers can use CAD to design parts that use fewer materials or are more efficient in their use of energy. Also, CAD allows designers to experiment with designs that are easier to recycle, reducing the environmental impact of the final product.

- Material optimization

- Energy-efficient designs

- Reduced waste

CAD helps create products that are both functional and environmentally friendly, leading to a more sustainable future.

The Future of CAD: Emerging Trends and Technologies

The future of CAD is bright, with new trends and technologies constantly emerging. Here are a few of the exciting developments:

- Cloud-Based CAD: Cloud technology allows CAD to be accessed from anywhere, anytime, making it easier for teams to collaborate and work remotely.

- Artificial Intelligence (AI): AI can analyze designs and make suggestions for improvements, helping designers make better decisions faster.

- Virtual Reality (VR): VR allows designers to interact with their CAD models in 3D, providing a more immersive experience.

- Augmented Reality (AR): AR is expected to make CAD even more interactive, allowing designers to see digital models in the real world.

As these technologies continue to evolve, computer aided design will become even more powerful, enabling even more innovative designs.

Challenges of Adopting CAD in Design and Engineering

Although computer aided design offers many benefits, it’s not without challenges. One of the main hurdles is the cost. High-end CAD software can be expensive, especially for small businesses or individual designers.

Another challenge is the learning curve. CAD software is complex, and it can take time to master. Even experienced engineers may need training to fully understand the capabilities of the software.

- High costs

- Learning curve

- Hardware requirements

So, despite these challenges, the advantages of CAD make it a valuable investment for anyone in the design and engineering fields.

How CAD Is Transforming Manufacturing Processes

Beyond design, CAD is also transforming manufacturing. Traditionally, manufacturing processes involved a lot of trial and error. But with computer aided design, engineers can simulate the entire manufacturing process before production begins.

For instance, CAD allows engineers to visualize how parts will be assembled, identify potential problems, and optimize the manufacturing process. And, this leads to reduced production time and cost, as well as fewer errors during the manufacturing stage.

- Simulated manufacturing process

- Improved efficiency

- Fewer errors

With CAD, manufacturing becomes more streamlined and cost-effective.

The Importance of CAD in Architecture and Construction

In architecture and construction, computer aided design has revolutionized the design process. It allows architects to create detailed blueprints, design 3D models, and simulate how buildings will perform in real-world conditions.

For example, using CAD, architects can design energy-efficient buildings by testing how sunlight and airflow affect the structure. Also, this technology makes it easier to collaborate with engineers and construction teams, ensuring that the project runs smoothly from start to finish.

- Detailed blueprints

- Energy-efficient designs

- Better collaboration

Reducing Errors in Production with CAD

One of the major advantages of computer aided design is its ability to reduce errors in production. With traditional methods, even small mistakes in design can lead to large issues later in the production process. Moreover, CAD helps prevent this by catching errors early in the design phase.

- Early error detection

- Fewer revisions

- Smoother production process

By catching issues early, CAD helps ensure that products are built right the first time.

Conclusion

Finally, Computer Aided Design has completely transformed the way we approach engineering and design. From improving precision and creativity to making collaboration easier, CAD is reshaping industries around the world. As we move into the future, Computer-aided design will continue to play a vital role in product development, sustainability, and innovation.

So, how do you think computer aided design will continue to shape the future of design and engineering?

FAQs

What is CAD, or computer-aided design?

CAD stands for “computer-aided design.” This is the process of using computer software to make, change, study, or improve designs. It helps designers, architects, and engineers make digital models of buildings, systems, and goods that are very detailed. Computer Aided Design is used in many fields to make designs more accurate, cut down on mistakes, and speed up production.

How does CAD make the process of designing better?

CAD makes the design process better by letting designers make accurate digital models, make changes quickly, and test designs online. Compared to traditional methods, this cuts down on time, costs, and mistakes, allowing faster creation of more accurate and useful products.

Why is CAD important in engineering?

CAD is very important in engineering because it helps engineers model and study how a design will work before they build it. It also makes precision possible and lowers the chance of mistakes. From idea to manufacturing, this raises the general calibre and effectiveness of engineering projects.

How does CAD help people work together on design projects?

CAD makes it easier for people to work together because it lets everyone on the team work on the same design at the same time, from anywhere. A lot of CAD programs have cloud-based features that let you get updates, get comments, and share files and ideas easily. This makes sure that everyone on the team is on the same page and can add to the project well.