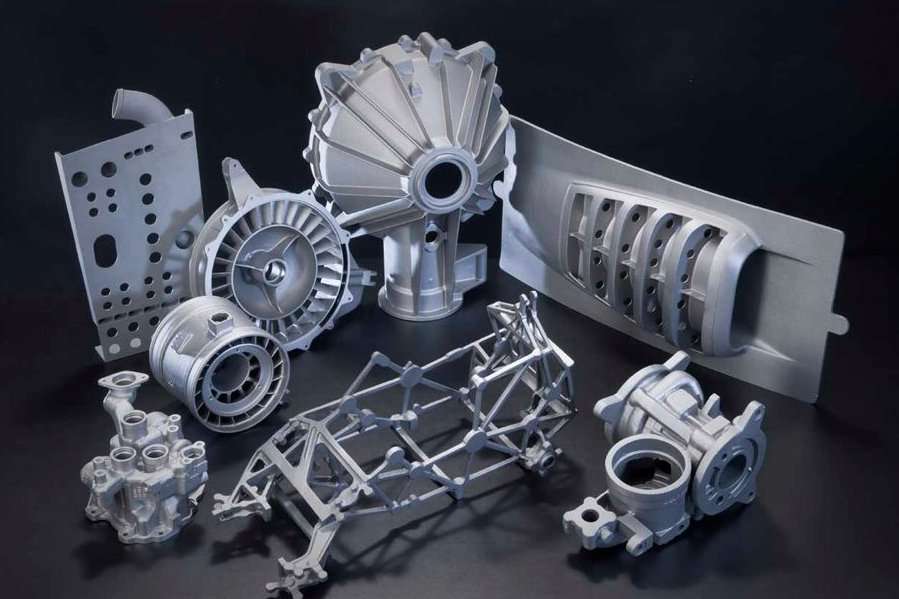

Die casting is a precision manufacturing process that involves forcing molten metal into a mold cavity under high pressure, producing highly accurate, durable, and smooth metal parts. Ideal for complex designs.

In our facility, you have a variety of machines for part production, including CNC turning lathes, milling machines, injection molding equipment, state-of-the-art 3D printing technology, and more.

At XC Machining, we try to ensure your choice is not limited, which is why we offer over 60 materials for you to choose from for your prototypes and products.

In-depth service engineers with the knowledge to address your manufacturing inquiries are available from XC Machining. Our engineers are always on the ground to offer valuable advice.

We offer a range of surface treatments and custom finishes on solid metal and plastic parts, including anodizing, spray painting, vapor polishing, sandblasting, silk screening, etc.

Aluminum alloy is the most common metal used for die casting purposes. This is due to its remarkable strength-to-weight ratio, easy-to-use and recyclable characteristics, and good mechanical properties. Cold chamber die casting is often used to manufacture aluminum alloys.

Zinc alloys are the most economical and powerful for die casting. It provides great surface finishing options with convenient casting properties. High tolerances and extreme details are some features of zinc alloys.

Magnesium alloys are the best when it comes to preventing thermal cracks in die casting molds. Complex cavities are conveniently filled with magnesium alloys. Some of the primary properties of these alloys are as follows.

Custom die cutting at XC Machining produces precise cuts with clean edges, but additional surface finishes may be required to enhance the part’s appearance, functionality, and durability.

Die cutting typically provides a smooth edge with minimal burrs, resulting in a clean and precise cut without extensive post-processing.

Deburring removes sharp edges and small imperfections left after the die cutting process, ensuring that parts are safe to handle.

A brushed finish adds a uniform matte texture to die-cut parts, offering an elegant and aesthetically pleasing surface that reduces visible marks.

Polishing gives die-cut parts a high-gloss, mirror-like finish, ideal for applications where both appearance and smoothness are required.

Anodizing enhances the durability of metal die-cut parts by creating a protective oxide layer, available in both matte and glossy finishes.

Powder coating provides protective finish for die-cut parts, offering excellent resistance to corrosion, wear, and UV degradation in a variety of colors.

Custom die cutting at XC Machining produces precise cuts with clean edges, but additional surface finishes may be required to enhance the part’s appearance, functionality, and durability.

Die cutting typically provides a smooth edge with minimal burrs, resulting in a clean and precise cut without extensive post-processing.

Deburring removes sharp edges and small imperfections left after the die cutting process, ensuring that parts are safe to handle.

A brushed finish adds a uniform matte texture to die-cut parts, offering an elegant and aesthetically pleasing surface that reduces visible marks.

Polishing gives die-cut parts a high-gloss, mirror-like finish, ideal for applications where both appearance and smoothness are required.

Anodizing enhances the durability of metal die-cut parts by creating a protective oxide layer, available in both matte and glossy finishes.

Powder coating provides protective finish for die-cut parts, offering excellent resistance to corrosion, wear, and UV degradation in a variety of colors.

XC Machining is a trusted partner for industries demanding complexity, reliability and precision. Our expensive experience in producing millions of high quality components brings unmatched expertise to every project.

Our services cover a diverse range of applications to ensure that we meet the unique needs of each sector with great care.

XC Machining supports the automotive industry with cutting-edge CNC machining solutions, enabling the production of complex parts that drive efficiency

For the semiconductor industry, XC Machining offers CNC machining services that meet the high precision demands necessary for manufacturing components

Our CNC machining services are pivotal in the energy sector, where precision and durability are essential. XC Machining supports the

XC Machining is a trusted partner in the industrial machinery sector, offering CNC machining solutions that ensure the robust and

XC Machining delivers precision machining solutions for the electronics industry, producing intricate components that meet the exacting standards required for

XC Machining offers specialized CNC machining services for the communications industry, crafting precision parts that are vital for the infrastructure

Get reliable vacuum casting services for high-quality prototypes and production parts at competitive prices. XinCheng offers highly detailed casting parts with consistent quality.

Sheet metal fabrication uses cutting, bending, and forming techniques to create precision metal components for industrial, commercial, and manufacturing applications.

Leverage our injection molding services for high-quality prototypes and custom parts, with expert support, competitive pricing, and faster production cycles for reliable, efficient results.

From the commercial and consumer level up to the aerospace industry, die casting has numerous applications. Some of the prominent applications of it are as under.

Copyright © 2026 XC Machining

Copyright © 2026 XC Machining