In the medical manufacturing industry, the demand for precise components that meet stringent standards has seen rapid growth. Medical CNC machining is the preferred choice for creating components that require meticulous accuracy, biocompatibility, and reliable production. With the flexibility to work with a wide variety of materials, CNC machining ensures that medical products meet industry quality and safety standards, providing peace of mind to healthcare professionals and patients alike.

Perks of Choosing XC Machining for Medical CNC Solutions:

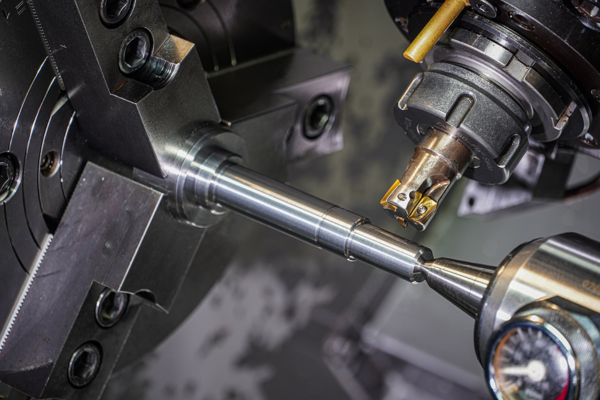

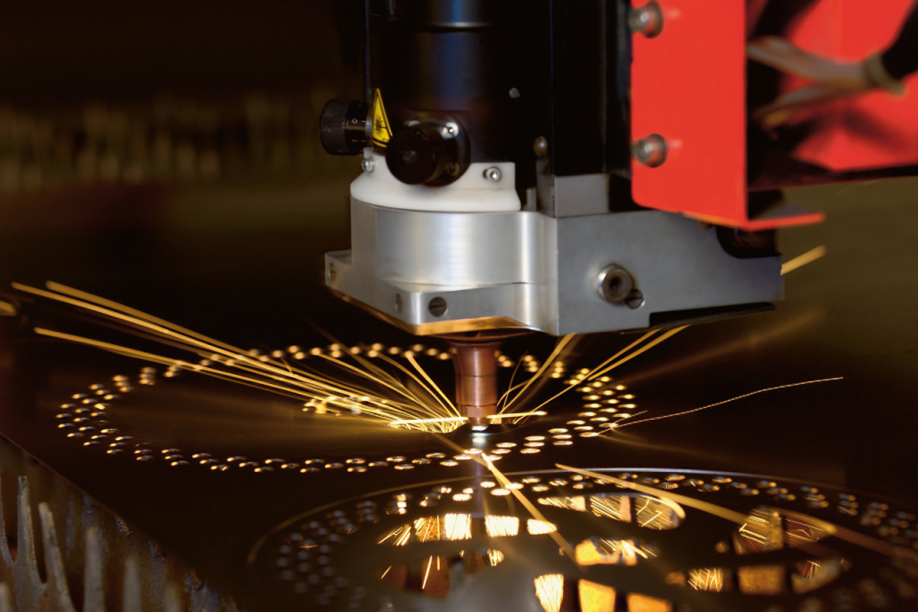

- CNC Milling and Turning: We utilize advanced 3- and 4-axis CNC milling machines to produce complex medical components with tight tolerances. Our CNC turning capabilities allow us to create intricate cylindrical parts essential for various medical devices.

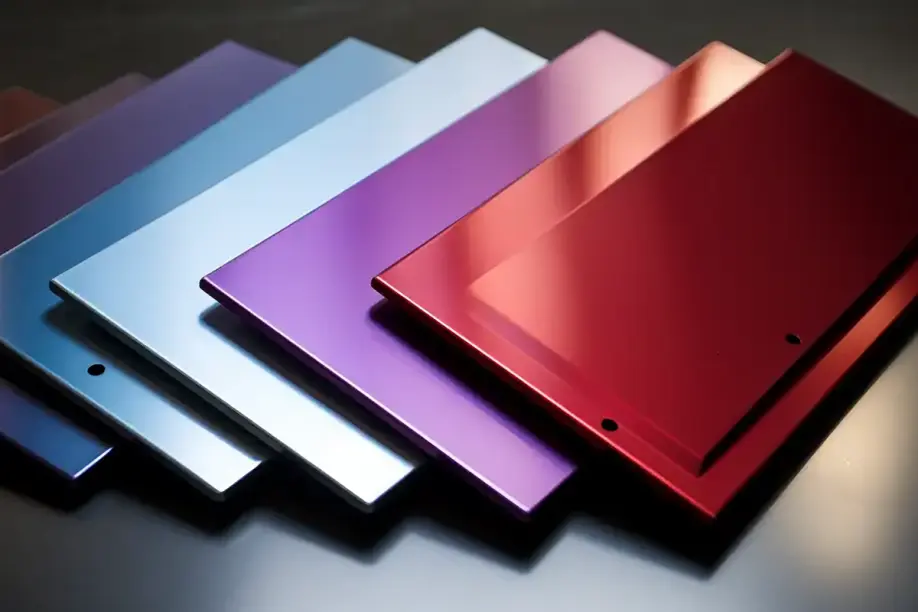

- Materials Expertise: We work with a wide range of biocompatible materials, including stainless steel, titanium, aluminum, and medical-grade plastics such as PEEK and PVC, ensuring the suitability of each component for its intended medical application.

- Rapid Prototyping and Production: Our efficient processes enable quick turnaround times for both prototypes and low-volume production runs, facilitating faster development and time-to-market for medical devices.

CNC Machining for the Medical Industry

The medical manufacturing sector has witnessed a significant increase in the demand for highly precise components that adhere to strict tolerances. These components must meet rigorous quality and safety standards while ensuring efficient and reliable production. Medical CNC Machining has emerged as the preferred solution for product designers and manufacturers in the healthcare industry.

With its unmatched versatility and ability to work with a wide range of materials, CNC machining is ideal for creating medical components with exceptional precision and accuracy. This process ensures the production of reliable, biocompatible parts that prioritize patient safety and reduce the risk of errors, making it an invaluable asset to the medical field.

Why Choose XC Machining for Medical Components?

- Precision and Accuracy: Our state-of-the-art CNC machinery and experienced technicians ensure that every part meets exact specifications, which is critical for medical applications where precision is paramount.

- Quality Assurance: We adhere to stringent quality control measures throughout the manufacturing process, ensuring that each component complies with industry standards and regulations.

- Customization: We offer customized solutions to meet the unique requirements of each client, from material selection to surface finishes, ensuring that the final product aligns with your specific needs.

- Experience: With years of experience in the medical manufacturing sector, we understand the complexities and demands of producing medical-grade components.

Applications of Our Medical CNC Machining Services

Our precision machining services cater to a variety of medical applications, including:

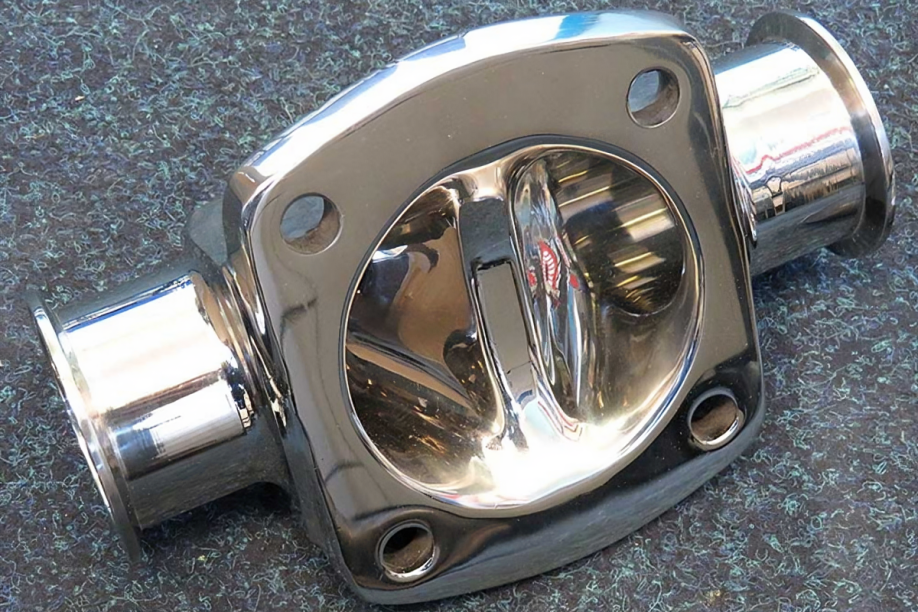

- Surgical Instruments: Manufacturing of high-precision tools used in surgical procedures.

- Implantable Devices: Production of components for implants requiring biocompatibility and precision.

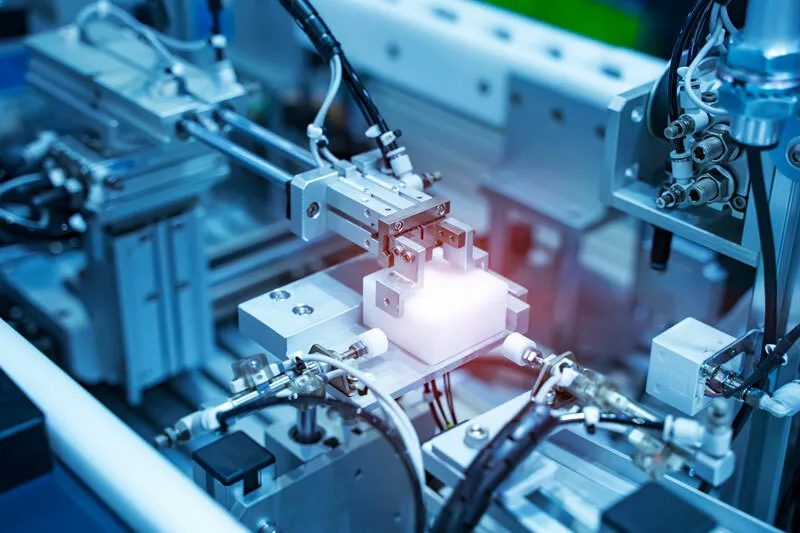

- Diagnostic Equipment: Fabrication of parts for machines used in medical diagnostics.

- Laboratory Equipment: Creation of precise components for laboratory instruments.

Medical CNC Solutions: Precision That Elevates Patient Care

The medical manufacturing industry relies on precision, reliability, and uncompromising quality. As the demand for high-accuracy components continues to grow, Medical CNC Machining has become the go-to solution for producing critical medical parts. From surgical tools to implantable devices, CNC machining offers exceptional precision, biocompatibility, and consistency. Its versatility in handling a wide range of materials ensures that medical products not only meet but exceed industry standards for safety and performance, giving healthcare professionals and patients the confidence they deserve.

Partner with XC Machining for your medical CNC machining needs and experience the highest level of precision and quality in the industry. Contact us today to discuss your project requirements and learn how we can assist in bringing your medical devices to market efficiently and effectively.