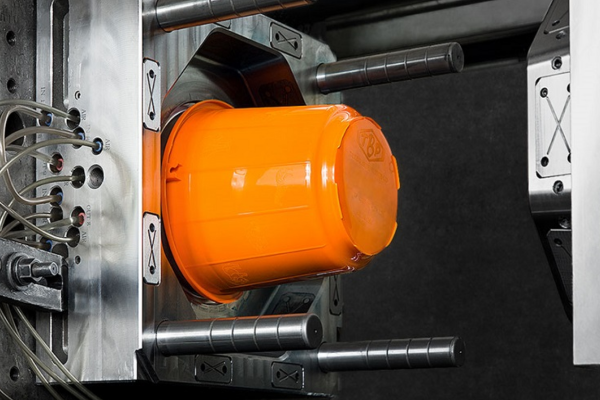

Insert molding offers several benefits, including reduced assembly time, improved part strength, and enhanced functionality by combining metal inserts with plastic components in a single mold. This method eliminates the need for additional assembly steps and ensures a more reliable, cost-effective manufacturing process, making it ideal for complex parts used in high-performance applications.