XC Machining supports the automation industry with cutting-edge CNC machining solutions, enabling the production of complex parts that drive efficiency and innovation in automated systems and processes. change this Automative Industry

a1

XC Machining supports the automation industry with cutting-edge CNC machining solutions, enabling the production of complex parts that drive efficiency and innovation in automated systems and processes. change this Automative Industry

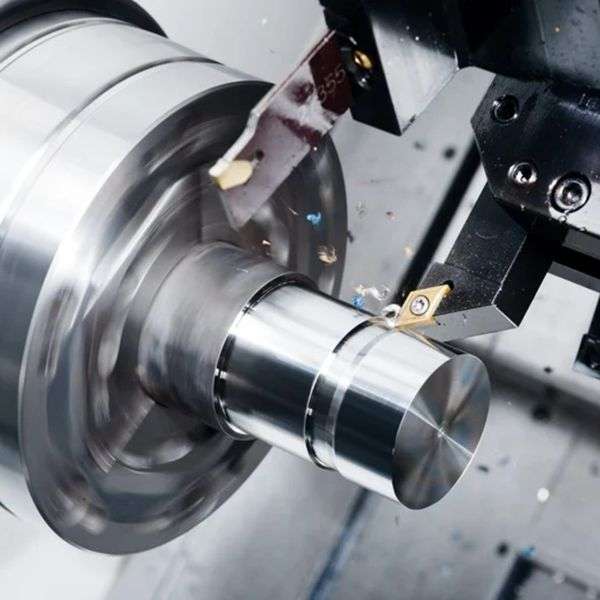

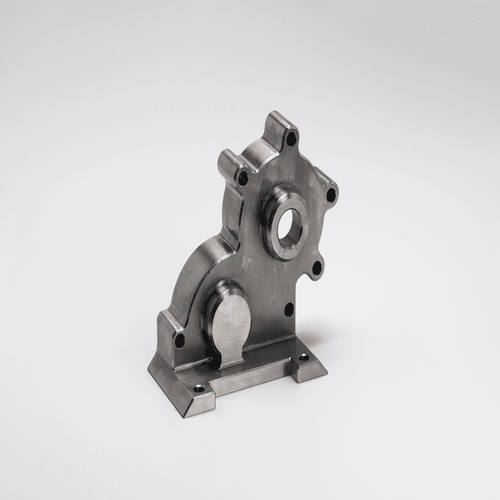

Our state-of-the-art facilities are equipped with advanced CNC machining, die casting, and surface finishing technologies, ensuring precision, efficiency, and quality in every project. From design to assembly, we support diverse industries with customized solutions tailored to meet the highest industry standards.

Discover unparalleled excellence in aerospace and aviation manufacturing with our state-of-the-art capabilities, delivering precision and reliability every step of the way.

We offer an extensive array of material options, catering to prototyping through full-scale production needs. Choose from more than 30 metal alloys and hundreds of high-performance plastics.

At XC Machining, we understand the importance of selecting the right materials for your automation projects. We offer an extensive array of material options, catering to both prototyping and full-scale production needs.

Alloy steel

High-Performance Plastics

We offer an extensive array of material options, catering to prototyping through full-scale production needs. Improve durability and performance with a selection of finishes

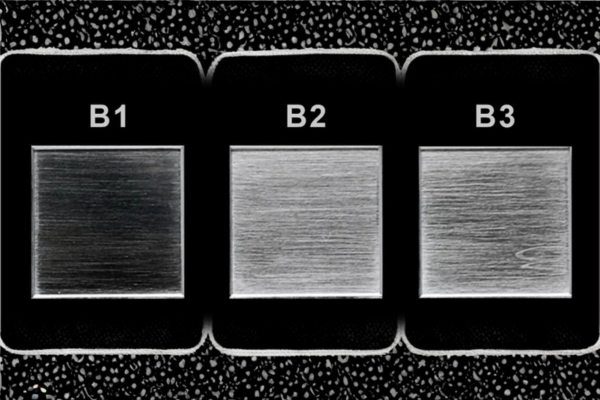

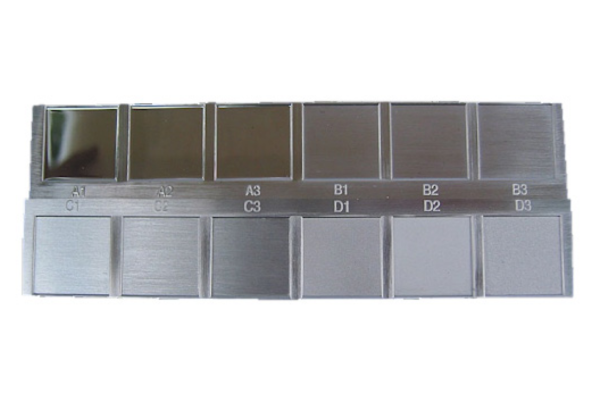

Injection mold tooling refers to the tools used to create molded parts. The surface finish of the tooling affects the final part quality and longevity.

Polishing is essential for the mold cavity to ensure smooth surface finishes on the molded parts, reducing part defects and enhancing product quality.

Texturing is applied to mold surfaces to create a patterned finish on molded parts, providing functional properties such as improved grip and aesthetic appeal.

Hard coating is applied to injection mold tooling to improve wear resistance and extend the lifespan of the tooling, especially for high-volume production.

Electropolishing is used to improve the surface smoothness and corrosion resistance of injection mold tools, ensuring long-term use without degradation.

Sanding removes imperfections from mold surfaces, ensuring the mold cavity is smooth and defect-free, which results in better-quality molded parts.

Vibratory finishing helps smooth out mold surfaces, removing small defects and ensuring consistent quality in the molded parts, especially for high-precision tooling.

Explore how our pioneering methods are revolutionizing the robotics and automation sector, driving efficiency, and shaping the industry’s future landscape.

Musicion ensures competitive pricing, robust IP protection, and expert design for manufacturability (DFM) guidance. Receive upfront pricing inclusive of shipping, quality control, and customs clearance. Our focus on IP security guarantees the confidentiality of your designs. Our mechanical engineers offer personalized DFM analysis to optimize your projects.

Expect precision and punctuality with Musicion. Our rigorous quality control procedures and vetting process for manufacturing partners ensure adherence to the highest standards. We conduct thorough inspections in Amsterdam and Chicago to verify functionality and cosmetic specifications. From order to delivery, we manage customs clearance requirements to ensure on-time delivery, every time.

Mitigate supply chain risks with Musicion's global and local sourcing capabilities. Access a diverse network of industrial specialists in 3D printing, CNC machining, injection molding, and sheet metal fabrication. Whether for aerospace or aviation projects, our consistent capacity and compliance solutions ensure reliability and resilience in your supply chain.

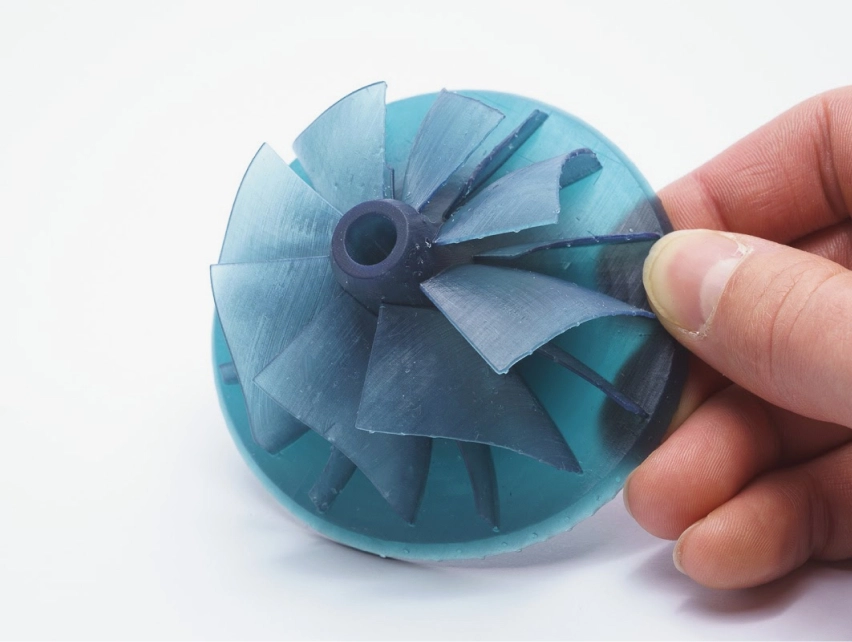

Get reliable vacuum casting services for high-quality prototypes and production parts at competitive prices. XinCheng offers highly detailed casting parts with consistent quality.

Sheet metal fabrication uses cutting, bending, and forming techniques to create precision metal components for industrial, commercial, and manufacturing applications.

Leverage our injection molding services for high-quality prototypes and custom parts, with expert support, competitive pricing, and faster production cycles for reliable, efficient results.

Custom and specialized die casting services for all types of metal parts as well as customized products. High-Precision die casting parts to meet your needs. Request to get a quote today!

With 3, 4, and 5-axis CNC machining services, we can produce complex prototypes and parts with precise tolerances. More than 60+ materials are available for you to choose from.

Get high-quality custom 3D printing services for prototype and production parts. Whether SLS or SLA, we deliver efficient solutions to meet your design and production goals without limitations.

Discover the genuine experiences of our customers. Their words carry more weight than our claims. Explore how we’ve exceeded expectations and fulfilled unique requirements.

XC Machining has been an outstanding partner for our product development. Their team provided best design solutions that helped us improve our parts and reduce costs. The prototypes were delivered on time and exceeded our quality expectations

Edward Starc

“Great quality, excellent service! XC Machining’s prototyping solutions streamlined our production timelines without sacrificing quality. I recommend them for precise, custom manufacturing.”

Mark D.

“XC Machining’s quick quotes and attention to detail were exceptional. Their expertise brought our design to life promptly. A dependable partner for innovative projects.”

Sophia L.

“The materials and finishes available at XC Machining are top-notch. Their DFM analysis greatly improved our design, and the pricing was excellent. Highly recommended!”

Liam T.

“Exceptional service! XC Machining delivered quality prototypes quickly, and their support team was highly responsive. I highly recommend them for reliable, custom manufacturing solutions.”

Emma R.

“XC Machining exceeded our expectations in both precision and speed. The team ensured our specifications were met, making them our trusted partner for rapid prototyping and manufacturing.”

John S.

Experience precision engineering with XC Machining. From detailed prototypes to high-volume production, we’re here to turn your concepts into reality. Contact us today to discuss your project needs!

q1

a1

Copyright © 2026 XC Machining

Copyright © 2026 XC Machining