Have you ever wondered how those sleek, perfectly designed products like your smartphone, car parts, or even the toys you play with are made? The answer often lies in something many people overlook molding. Yep, molding services are the secret sauce behind many high-quality products. If you think about it, every plastic part you use, every smooth surface you touch, and even those oddly shaped pieces that fit perfectly together chances are they were made using molding services.

Now, let’s break down what molding service really are and why they’re crucial for creating products that stand out in both quality and durability. Whether you’re working on a new product line, designing a prototype, or looking to manufacture a large volume of items, understanding molding can give you an edge over your competitors.

What Are Molding Services?

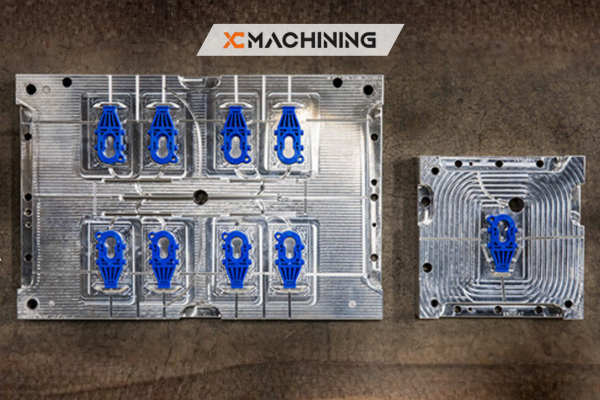

Molding services are specialized processes used to create precise, repeatable shapes in materials like plastic, metal, or rubber. The most common types of molding include injection molding, compression molding, and blow molding. In each case, raw materials are heated until they become pliable and then injected or pressed into molds to form the desired shape.

For example, think about how plastic bottles are made. A plastic pellet is heated up, and then it’s blown into a mold that gives it the shape of a bottle. This is the magic of Injection Molding. It’s like baking a cake mix the ingredients (materials), put them in a mold (the pan), and voila! You have a finished product. The best part? Molding can create thousands of identical products with minimal human intervention, making it perfect for mass production.

Why Molding Services Are So Important

Imagine you’re trying to create a product, but the materials you use are tough to shape or don’t hold up over time. You’d probably be stuck, right? This is where expert molding services come in. When you hire a company that specializes in molding, they ensure that the process is precise, cost-effective, and sustainable. Without reliable molding service, many industries would struggle to produce the high-quality goods consumers expect.

Here’s why molding is so crucial:

- Consistency: Molding ensures that each product is identical. No flaws, no mistakes.

- Durability: The right molding service ensures products can stand the test of time, resisting wear and tear.

- Customization: Whether it’s a one-off prototype or thousands of items, molding can accommodate both small and large production runs.

Businesses may produce goods that are both aesthetically beautiful and useful by utilizing the power of molding.

Molding Service Types

Molding processes come in a variety of forms, each tailored to specific materials and manufacturing requirements. Let’s examine a few of the most prevalent ones:

The process of injection molding

The most popular method for creating plastic injection mold. It entails applying tremendous pressure while pumping molten plastic into a mold. This process is fast, efficient, and perfect for making high-volume parts like bottle caps, containers, and even parts for electronics.

Benefits of Injection Molding:

- High-speed production

- Great for detailed designs

- Create intricate textures and shapes

- Cheap production costs for large quantities

2. Molding by Compression

Rubber and thermosetting polymers are commonly molded via compression molding. After being put in a mold cavity, the material is heated and compacted. This method is ideal for creating large, durable parts, like automotive bumpers or industrial seals.

Benefits of Compression Molding:

- Ideal for large, bulky parts

- Lower tooling costs

- Excellent for high-strength materials

3. Blow Molding

Blow molding is used for making hollow plastic parts. This is the process behind creating items like plastic bottles, drums, and tanks. The molten plastic is inflated inside a mold to form a hollow shape.

Benefits of Blow Molding:

- Perfect for hollow items

- Efficient for high-volume production

- Low material waste

Each type of molding has its strengths, and the right one depends on the material and type of product you’re looking to create. The quality of the finished product can be greatly influenced by the skill involved in each molding procedure.

Innovation in Products and Molding Services

For companies hoping to stay ahead of the competition, product innovation is essential. Molding services play a significant role in facilitating this innovation. By allowing designers and engineers to experiment with complex shapes, textures, and materials, molding opens the door to creative possibilities that would be impossible with traditional manufacturing methods.

Take, for example, the tech industry. Many electronics, like smartphones and laptops, rely on precise, intricate parts made through low volume injection molding. This process enables the production of ergonomic, sleek, and lightweight designs, providing a competitive edge in a crowded market. Whether it’s a unique shape or a special function embedded in the design, molding services allow for a level of product flexibility that fosters innovation. Plus, advanced techniques like rapid prototyping enable companies to test designs quickly and make real-time changes, enhancing the creative process.

Molding services are a vital tool for companies looking to push boundaries and bring fresh, innovative products to life.

Benefits of Expert Molding Services

So, why should you trust expert molding services for your next project? Well, it all boils down to quality, efficiency, and cost-effectiveness. Here’s a closer look at the benefits of working with professionals in this field:

- High-Quality Products: Molding services guarantee precision, meaning your products will have the perfect fit, finish, and functionality. No matter the design, you can trust that the final result will meet your expectations.

- Reduced Costs: By using molding, businesses can produce large quantities of parts or products quickly, lowering the cost per unit. You’ll spend less on materials and labor, and your products will still be top-notch.

- Faster Turnaround: Need your products ready in a hurry? Molding services speed up production times, ensuring you get your product to market faster. When every day counts, this is a big advantage.

In fact, companies that use professional molding services often see a 20-30% reduction in production time compared to traditional manufacturing methods. Talk about efficiency!

How Expert Molding Services Ensure Consistency

Have you ever bought a product that looked great in the store, but when you used it, it didn’t work quite right? It might’ve been due to poor manufacturing or inconsistencies in production. Consistency is key to ensuring customer satisfaction, and expert molding services excel in this area.

When you use molding services, you get:

- Exact Replication: Every product comes out the same way, which is especially important for industries like automotive or electronics, where precision is everything.

- Quality Control: Experienced molding companies use strict quality control measures to ensure that every item meets the required standards before it’s shipped out.

This level of consistency makes molding the go-to method for many large-scale manufacturers.

How Molding Services Improve Manufacturing Efficiency

In today’s fast-paced market, efficiency is key to staying competitive. Expert molding services improve manufacturing efficiency by streamlining the production process. Once the molds are designed and tested, they can be used for high-volume production runs with minimal downtime. This means manufacturers can produce large quantities of items in less time, lowering labor costs and reducing waste.

Additionally, molding machines are highly automated, which reduces human error and increases consistency across all produced parts. This automation speeds up the process, eliminates injection molding cost mistakes, and improves the overall quality of the finished product. By reducing setup times and improving production schedules, molding help businesses deliver products faster to meet customer demand. In some cases, manufacturers have been able to cut production time by up to 40%, allowing them to bring products to market more quickly and effectively.

By integrating molding into the production line, businesses experience a substantial boost in operational efficiency, leading to better profitability.

Cost-Effectiveness of Molding Services

Let’s talk numbers. Molding might seem like an expensive option up front, but when you consider the savings in the long run, it makes sense. Here’s how:

- Lower Labor Costs: Since the process is mostly automated, there’s less need for manual labor. This cuts down on overhead costs.

- Material Efficiency: Molding processes are highly efficient in terms of material use, meaning you waste less raw material, which translates to savings.

- High-Volume Production: Once the molds are created, producing large quantities of parts is relatively cheap. The more you produce, the lower the cost per unit.

Many companies see their costs drop by as much as 40-50% after switching to molding for large-scale production. This kind of efficiency helps businesses maximize profits without sacrificing quality.

Molding Services for Different Industries

Molding isn’t just for making toys or bottles. It’s a versatile service used in almost every industry today. From electronics to automotive to medical devices, molding is crucial for producing high-quality products. Let’s take a look at a few industries that benefit from expert molding service:

- Automotive Industry: Car parts, such as bumpers, dashboards, and interior components, are often made using molding services. These parts need to be strong, durable, and consistent, making molding an ideal choice.

- Electronics: Smartphone casings, tablet shells, and other electronic components are frequently created using molding. The precision and ability to create complex shapes are vital for these products.

- Medical Devices: Medical devices need to meet stringent safety and quality standards, and molding services ensure that these products are manufactured with precision and care.

Each of these industries depends on molding services to create products that are both functional and reliable.

The Environmental Impact of Molding Services

In today’s world, sustainability is becoming a bigger concern. Every business, big or small, is trying to find ways to lower their environmental footprint. The good news? Molding services can be a great way to achieve this!

Here’s why molding services can be more eco-friendly:

- Reduced Waste: Molding is an efficient process that generates less waste compared to other manufacturing methods.

- Recycled Materials: Some molding processes allow for the use of recycled materials, which reduces the need for new raw materials.

- Energy Efficiency: Modern molding machines are designed to use less energy, lowering overall environmental impact.

By opting for molding services, companies can make products with a smaller carbon footprint while still meeting the needs of the market.

How Molding Services Improve Product Design

Sometimes, creating a new product requires a perfect blend of creativity and engineering. Fortunately, undercuts in injection molding can improve product design in ways traditional manufacturing can’t. Let’s break down how molding service can enhance the design process:

- Complex Geometries: Molding allows designers to create intricate shapes that would be impossible or too expensive with other methods.

- Design Flexibility: Whether you need to make quick design changes or create variations of a product, molding can accommodate these shifts.

- Prototyping: Molding makes it easier to prototype a design quickly, test it out, and make adjustments.

With molding services, product design can become more creative, functional, and versatile.

How Molding Services Help Meet Tight Deadlines

In business, deadlines are everything. Late deliveries can cause lost sales, unhappy customers, and a damaged reputation. Molding services help companies meet tight deadlines by offering fast, reliable, and efficient production methods. Since molding is an automated process, the production time is often much faster than other traditional manufacturing techniques.

Once the initial mold is designed and tested, producing parts becomes a quick and streamlined process. This speed helps companies react faster to market demand or unexpected shifts in consumer preferences. Additionally, molding allows for the production of large batches of identical parts without the need for constant adjustments, which can often delay projects. By relying on the automation and precision of molding, businesses can deliver high-quality products on time, even under pressure.

If you’re dealing with a rush order or a last-minute project, molding services can save the day by getting products out the door quickly without sacrificing quality.

Future Trends in Molding Services

The molding industry is not standing still. As technology advances, so do the molding techniques. Here’s a glimpse at some future trends that could reshape the industry:

- 3D Printing Integration: Some molding services are already starting to integrate 3D printing to create more intricate molds. This allows for quicker prototyping and greater flexibility in design.

- Sustainability: As industries push for greener practices, molding services are looking at ways to use recycled materials and reduce waste in the manufacturing process.

These innovations ensure that the molding industry will continue to meet the growing demands for quality products while staying ahead of the curve in terms of efficiency and sustainability.

Conclusion

So, now you know the secret behind high-quality products—molding! Whether you’re looking to create a new product, streamline production, or ensure consistency, molding service offer a world of benefits. From precision and durability to cost savings and faster production, it’s clear that expert molding is the backbone of modern manufacturing.

Are you ready to take your product to the next level with expert molding services? What do you think will be the next big thing in the world of molding?